For beekeepers looking to process their beeswax, the primary options are solar-powered and electric melters. The best choice depends entirely on the scale of your operation, with solar melters being ideal for hobbyists and electric models designed for the high-volume needs of commercial producers.

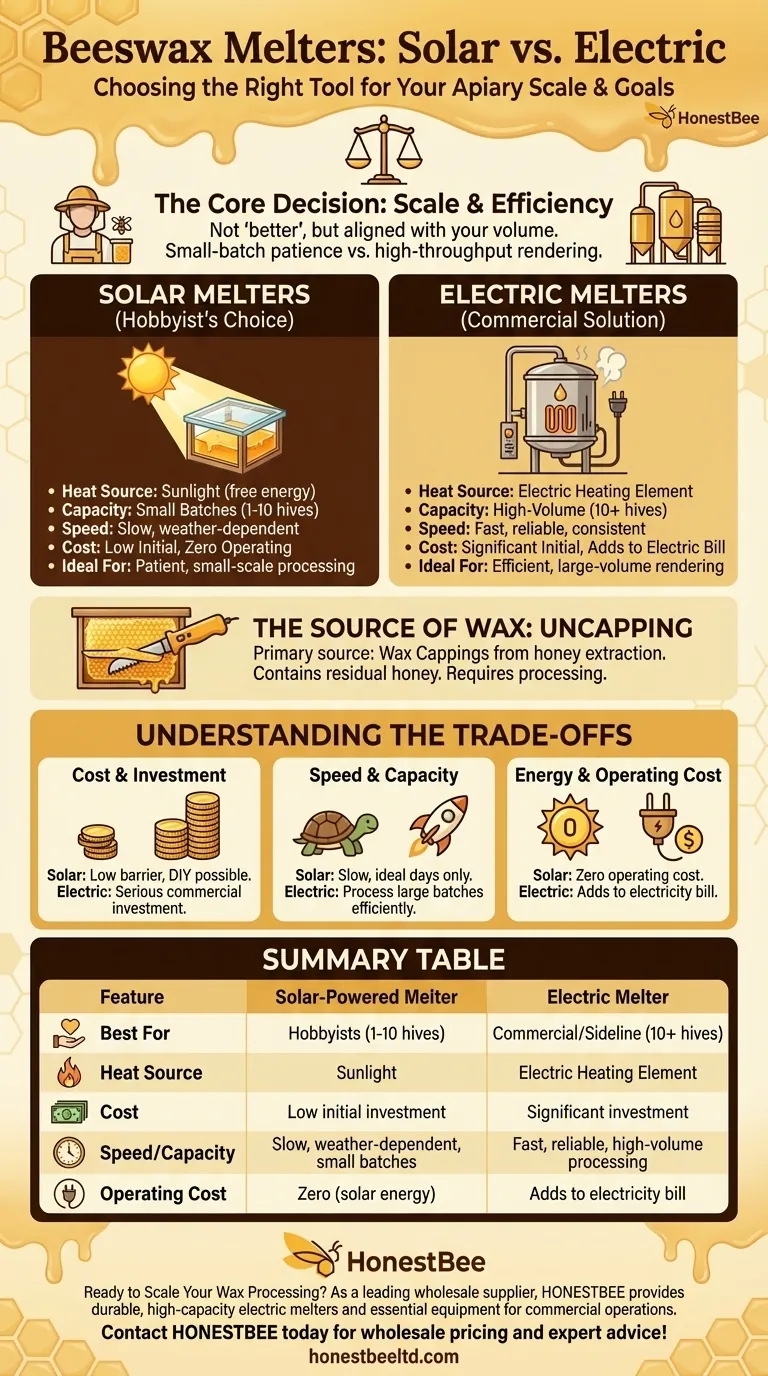

The core decision between a solar and electric beeswax melter is not about which is "better," but which tool aligns with your specific volume and efficiency needs. It's a choice between patient, small-batch processing and high-throughput, commercial-scale rendering.

The Two Primary Melter Technologies

Understanding how each type of melter works is the first step in determining which is right for your apiary. The fundamental difference lies in the heat source and the capacity it enables.

Solar-Powered Melters: The Hobbyist's Choice

A solar melter is essentially a well-insulated box with a glass or plastic top, designed to trap the sun's heat like a greenhouse. Inside, wax cappings or old comb are placed on a tray, and the heat melts the wax, which then drips through a filter into a collection pan.

This method is simple, effective for small quantities, and relies entirely on free energy from the sun.

Electric Melters: The Commercial Solution

Electric melters are high-capacity tanks with built-in heating elements that provide consistent, controllable heat. They are designed to process large quantities of beeswax cappings quickly and efficiently, regardless of the weather.

These units are a significant investment but are essential for commercial beekeepers who need to render hundreds of pounds of wax in a single season.

The Source of the Wax: Uncapping

The primary source of clean, high-quality wax for rendering comes from the wax cappings removed during honey extraction.

Processing Wax from Honey Frames

To extract honey, beekeepers must first slice off the thin layer of wax that seals each cell. This is typically done with a heated electric uncapping knife or a manual uncapping fork.

These wax cappings, full of residual honey, are what you will primarily process in your melter to produce clean beeswax blocks.

Understanding the Trade-offs

Choosing between solar and electric involves a clear set of compromises related to cost, speed, and capacity. Your goals will dictate which set of trade-offs is acceptable.

Cost and Initial Investment

Solar melters have a very low barrier to entry. They are relatively inexpensive to purchase, and many beekeepers build their own DIY versions.

Electric melters are a serious piece of commercial equipment and represent a significant financial investment, often costing many times more than a solar unit.

Speed and Capacity

The biggest limitation of a solar melter is its dependence on sunny, warm weather. Processing is slow and can only be done on ideal days, with a capacity suited for just a few hives' worth of cappings.

Electric melters offer speed and reliability. They can process large batches in a predictable timeframe, allowing a commercial operator to render all their season's wax efficiently.

Energy and Operating Cost

The key advantage of a solar melter is its operating cost: zero. It runs entirely on renewable solar energy.

An electric melter, while efficient, will add to your electricity bill. This operating cost must be factored into the profitability of your wax rendering.

Making the Right Choice for Your Operation

Your decision should be based on a realistic assessment of your beekeeping scale and goals.

- If your primary focus is hobby beekeeping (1-10 hives): A solar melter is the most economical and practical choice for processing your small batches of wax.

- If your primary focus is sideline or commercial beekeeping (10+ hives): An electric melter is a necessary investment to efficiently process large volumes of wax and maximize your return.

Choosing the right melter transforms wax rendering from a difficult chore into a valuable part of your beekeeping business.

Summary Table:

| Feature | Solar-Powered Melter | Electric Melter |

|---|---|---|

| Best For | Hobbyists (1-10 hives) | Commercial/Sideline (10+ hives) |

| Heat Source | Sunlight | Electric Heating Element |

| Cost | Low initial investment | Significant investment |

| Speed/Capacity | Slow, weather-dependent, small batches | Fast, reliable, high-volume processing |

| Operating Cost | Zero (solar energy) | Adds to electricity bill |

Ready to scale your wax processing?

As a leading wholesale supplier to commercial apiaries and distributors, HONESTBEE provides the durable, high-capacity electric melters and essential beekeeping equipment you need to run a profitable operation. Let us help you maximize your wax yield and efficiency.

Contact HONESTBEE today for wholesale pricing and expert advice tailored to your commercial needs!

Visual Guide

Related Products

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- 10L Stainless Steel Electric Honey Press Machine

People Also Ask

- What is the role of beeswax processing equipment? Maximize Your Apiary Profit Through Full Resource Utilization

- How can the beeswax cappings from honey extraction be processed and reused? Transform Waste into High-Value Gold

- What are the advantages of integrated electric heating tubes compared to traditional steam heating? Boost Your Efficiency

- What is the specific function of applying melted natural beeswax? Boost Your Hive Occupancy with Biological Lures

- What is the primary function of solar or steam wax melters in the initial processing of raw beeswax? Maximize Wax Purity