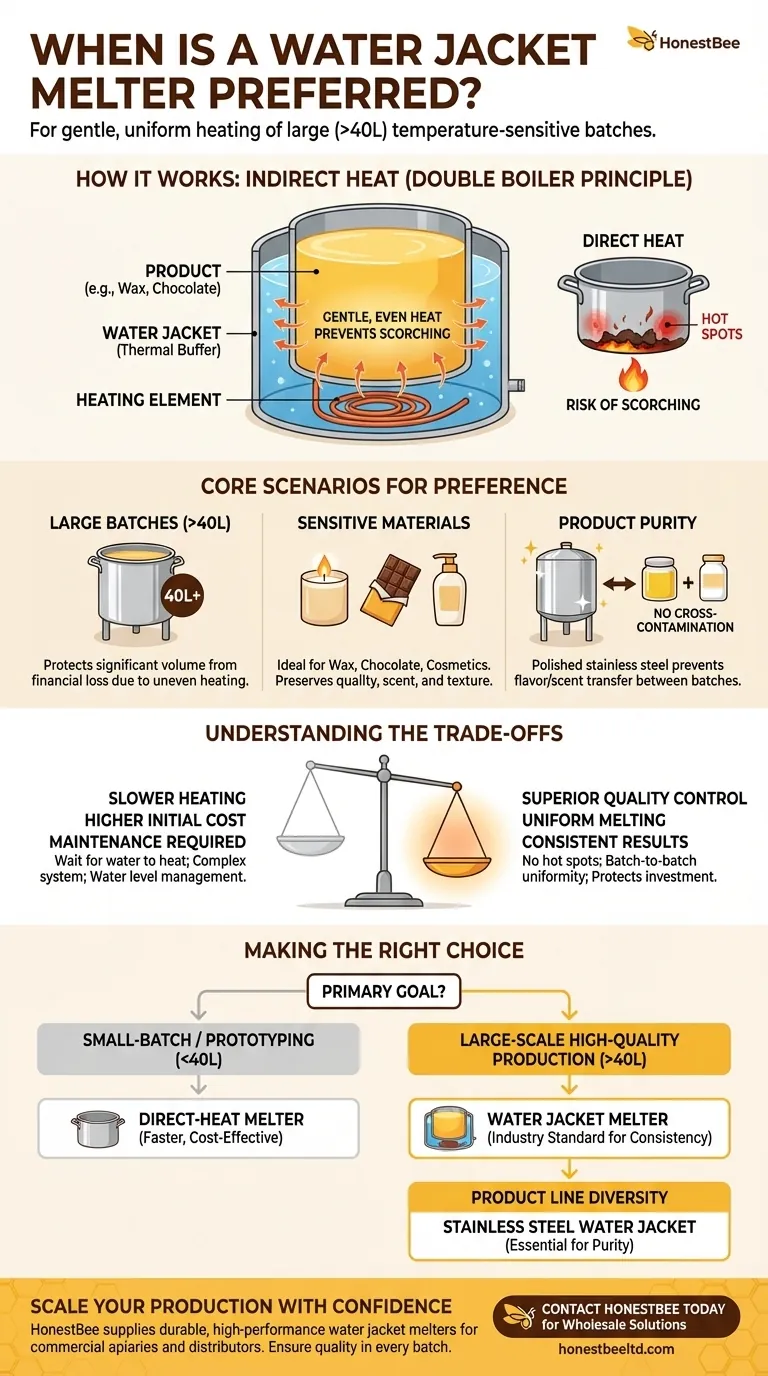

A water jacket melter is the preferred choice when you need to melt large volumes of temperature-sensitive material, specifically batches of 40 liters or more. Its design provides gentle, even heat that prevents scorching, which is a critical risk when working with materials like wax, chocolate, or cosmetic bases at a commercial scale.

The core reason to choose a water jacket melter is for quality control at scale. Its indirect heating method acts as a safeguard, ensuring the entire batch melts uniformly without hot spots that can degrade or ruin your final product.

How a Water Jacket Melter Works: The Principle of Indirect Heat

A water jacket melter functions like a large, industrial-grade double boiler. Understanding this simple principle is key to appreciating its value.

The "Double Boiler" Analogy

The melter consists of an inner tank to hold your product (e.g., wax) and an outer "jacket" that holds water. A heating element warms the water, and the hot water then transfers its heat evenly to the walls of the inner tank, melting the contents gently.

Why This Prevents Scorching

Direct-heat melters apply heat from an element directly to the bottom of the tank. This creates intense hot spots that can easily burn or "scorch" the material it touches, altering its chemical structure, color, or scent. A water jacket eliminates this risk by ensuring no part of the inner tank's surface gets hotter than the surrounding water.

Unmatched Temperature Stability

The large volume of water in the jacket acts as a thermal buffer. It heats up slowly and cools down slowly, preventing the rapid temperature fluctuations that can occur with direct-heat systems. This stability is crucial for achieving a consistent product from one batch to the next.

The Core Scenarios for Choosing a Water Jacket Melter

While its design is superior for gentle heating, a water jacket melter is not always the right tool. It is specifically suited for particular operational needs.

When Batch Size Exceeds 40 Liters

The 40-liter threshold is a practical guideline. Below this volume, the risk of scorching in a direct-heat melter can be managed more easily, and the faster heating time of direct heat is often an advantage. Above this volume, the financial loss from ruining a large batch of material makes the protective qualities of a water jacket a necessary investment.

When Working with Temperature-Sensitive Materials

Any material that can be damaged by overheating is a prime candidate for a water jacket melter. This includes:

- Waxes: Soy, paraffin, and beeswax can scorch, altering their burning properties and appearance.

- Chocolates and Confectionery: Overheating chocolate causes it to "seize" or lose its temper, ruining the texture.

- Soaps and Cosmetic Bases: Delicate oils, butters, and active ingredients can be degraded by excessive heat.

When Product Purity is Essential

If you produce multiple products using the same equipment, preventing cross-contamination is critical. High-quality water jacket melters are typically made of stainless steel. For operations using strong scents or dyes, a polished, non-porous internal finish is essential to prevent the tank walls from absorbing and transferring these agents between batches.

Understanding the Trade-offs

A water jacket melter offers superior quality control, but this comes with practical trade-offs compared to simpler direct-heat systems.

Slower Heating Times

The primary disadvantage is speed. You must wait for the entire volume of water to heat up before it can begin effectively melting your product. For small, quick jobs, this can be inefficient.

Higher Initial Cost and Complexity

These machines are more complex, often involving thermostats, water fill/drain ports, and more robust construction. This results in a higher upfront investment compared to a basic direct-heat pot.

Maintenance Requirements

The water in the jacket requires management. It must be kept at the correct level and may need occasional draining and cleaning to prevent mineral buildup, especially in hard water areas.

Making the Right Choice for Your Operation

Choosing your melter is an investment in your production workflow. Base your decision on your primary operational goal.

- If your primary focus is large-scale, high-quality production (>40L): A water jacket melter is the industry standard for ensuring batch consistency and protecting your raw materials.

- If your primary focus is small-batch prototyping or hobbyist work: A smaller, direct-heat melter is almost always more cost-effective and faster for your needs.

- If your primary focus is product line diversity: Invest in a water jacket melter with a polished stainless steel interior to ensure product purity when switching between different scents and colors.

Ultimately, choosing a water jacket melter is a decision to prioritize product quality and consistency as your operation grows.

Summary Table:

| Scenario | Reason for Preference |

|---|---|

| Batch Size > 40 Liters | Protects large, valuable batches from financial loss due to scorching. |

| Temperature-Sensitive Materials | Provides gentle, indirect heat to preserve the quality of wax, chocolate, etc. |

| Essential Product Purity | Polished stainless steel interior prevents cross-contamination between batches. |

| Requires Temperature Stability | Water acts as a thermal buffer for consistent results from batch to batch. |

Scale Your Production with Confidence

Protecting your valuable raw materials is non-negotiable for commercial success. HONESTBEE supplies durable, high-performance water jacket melters designed for the rigorous demands of commercial apiaries and beekeeping equipment distributors.

Our wholesale-focused operations ensure you get the reliable equipment you need to guarantee product quality and consistency in every batch.

Contact HONESTBEE today to discuss your commercial melting needs and explore our wholesale solutions.

Visual Guide

Related Products

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- 10L Stainless Steel Honey Wax Press Extractor for Wax Cappings

People Also Ask

- What makes polyurethane foam environmentally friendly? The Surprising Benefits of a Durable, Inert Material

- What happens to beeswax if it is heated beyond 170F? Prevent Irreversible Quality Loss and Darkening

- How do water jacket melters function? Achieve Gentle, Scorch-Free Melting for Sensitive Materials

- What are the main types of wax melters? Choose the Right Heating Method for Your Needs

- What are the primary products of honey bee farming besides honey? Discover the Hive's Hidden Treasures