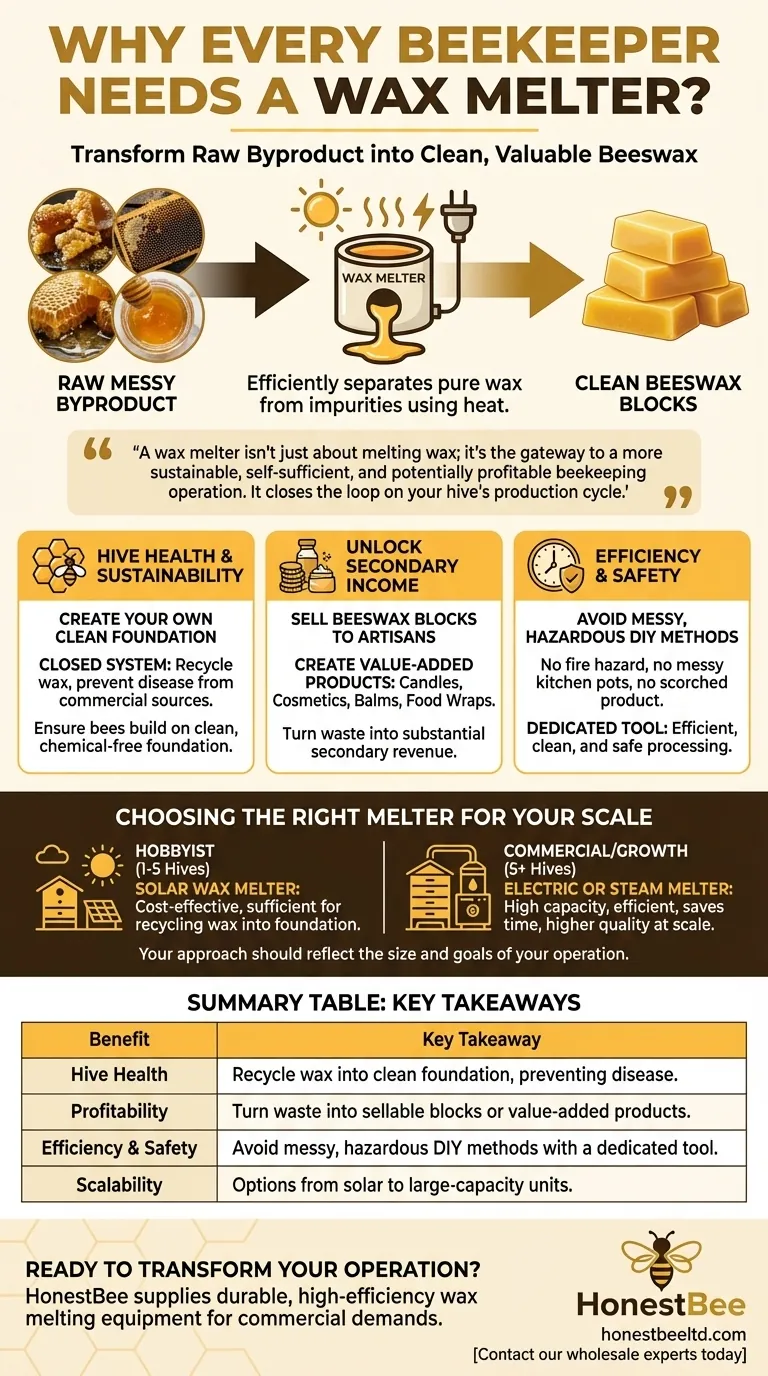

At its core, a wax melter is an indispensable tool because it allows a beekeeper to transform a raw, messy byproduct into one of their most valuable and versatile assets: clean beeswax. Without an efficient way to render wax from old combs and cappings, you are discarding a resource critical for both hive health and potential income.

A wax melter isn't just about melting wax; it's the gateway to a more sustainable, self-sufficient, and potentially profitable beekeeping operation. It closes the loop on your hive's production cycle.

Beyond Honey: Unlocking the Value of Beeswax

Many new beekeepers focus exclusively on honey, but seasoned apiarists know the immense value of the wax that protects it. A dedicated melter is the key to accessing this value.

From Raw Cappings to a Usable Product

After a honey harvest, you are left with wax cappings, old frames, and burr comb. In this raw state, it is a sticky mess mixed with honey residue and other debris.

A wax melter uses heat (from the sun, steam, or electricity) to separate the pure wax from these impurities, rendering it into clean, uniform blocks that are easy to store and use.

The Foundation of a Healthy Hive

The most critical use for your rendered beeswax is creating new foundation sheets for your frames. This is fundamental to sustainable beekeeping.

By recycling your own wax, you create a closed system. You ensure your bees are building on a clean foundation, free from potential diseases or chemical residues that can be present in commercially purchased wax. This directly contributes to hive health and disease management.

A Source of Secondary Income

Clean beeswax is a valuable commodity with high demand in numerous industries. Processing your own wax opens up diverse revenue streams beyond honey sales.

This includes selling blocks of wax to artisans or creating your own value-added products like candles, cosmetics, balms, and food wraps. For many beekeepers, this secondary income can be substantial.

Understanding the Trade-offs

While essential, the "need" for a melter must be weighed against your specific scale and goals. The upfront cost and type of equipment are important considerations.

The Problem with DIY Methods

Attempting to render wax in a standard kitchen pot is inefficient, incredibly messy, and a significant fire hazard. Wax is flammable, and this crude method often results in a lower-quality, scorched product that is difficult to clean.

Scale Dictates the Solution

The term "wax melter" covers a wide range of devices. Not every beekeeper needs a large, expensive electric unit.

For a hobbyist with just a few hives, a simple and inexpensive solar wax melter is often perfectly sufficient. For a commercial operation, a large-capacity steam or electric melter becomes a necessity for processing wax efficiently.

The Cost of Neglecting Wax

The truest cost is not the price of a melter, but the lost value of discarded wax. Every pound of wax you throw away is a pound you cannot use for new foundation or sell. Over just a few seasons, this lost potential easily surpasses the cost of a basic melter.

Making the Right Choice for Your Apiary

Your approach to wax rendering should directly reflect the size and goals of your beekeeping operation.

- If your primary focus is hobby beekeeping (1-5 hives): A simple solar wax melter is a highly cost-effective tool that will meet your needs for recycling wax into foundation.

- If your primary focus is growth and efficiency (5+ hives): Investing in an electric or steam-powered melter will save you significant time and produce a higher quality product at scale.

- If your primary focus is profitability: A quality melter is non-negotiable, as it is the machine that turns a waste product into a consistent, marketable commodity.

Ultimately, mastering the art of processing beeswax is a hallmark of a resourceful and accomplished beekeeper.

Summary Table:

| Benefit | Key Takeaway |

|---|---|

| Hive Health | Recycle wax into clean foundation, preventing disease from commercial sources. |

| Profitability | Turn waste into sellable blocks or value-added products like candles and balms. |

| Efficiency & Safety | Avoid messy, hazardous DIY methods with a dedicated, efficient tool. |

| Scalability | Options range from simple solar melters for hobbyists to large-capacity units for commercial apiaries. |

Ready to transform your beekeeping operation?

A wax melter is the key to a sustainable, healthy, and profitable apiary. At HONESTBEE, we supply durable, high-efficiency wax melting equipment and beekeeping supplies designed for the demands of commercial apiaries and beekeeping equipment distributors.

Let us help you close your production loop and maximize the value of every hive.

Contact our wholesale experts today to find the perfect wax processing solution for your scale.

Visual Guide

Related Products

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

People Also Ask

- What are the industrial and artistic applications for 100% pure, unbleached beeswax? Top Uses & Benefits

- What are the differences between soy wax and beeswax? A Guide to Choosing the Right Wax

- Why is specialized beeswax processing equipment vital for organic beekeeping? Secure Your Colony's Biological Integrity

- What precautions should be taken when melting beeswax? Ensure Safety and Preserve Quality

- How can steam be used to render wax from old brood comb? Efficient Wax Recovery for Commercial Apiaries

- What are the safety risks associated with different types of wax melters? A Comprehensive Safety Guide for Beekeepers

- How does the beeswax melting and recycling process contribute to standardized apiary management? Maximize Hive Efficiency

- What are the primary process objectives of beeswax heating and melting equipment? Optimize Your Wax Purity and Yield