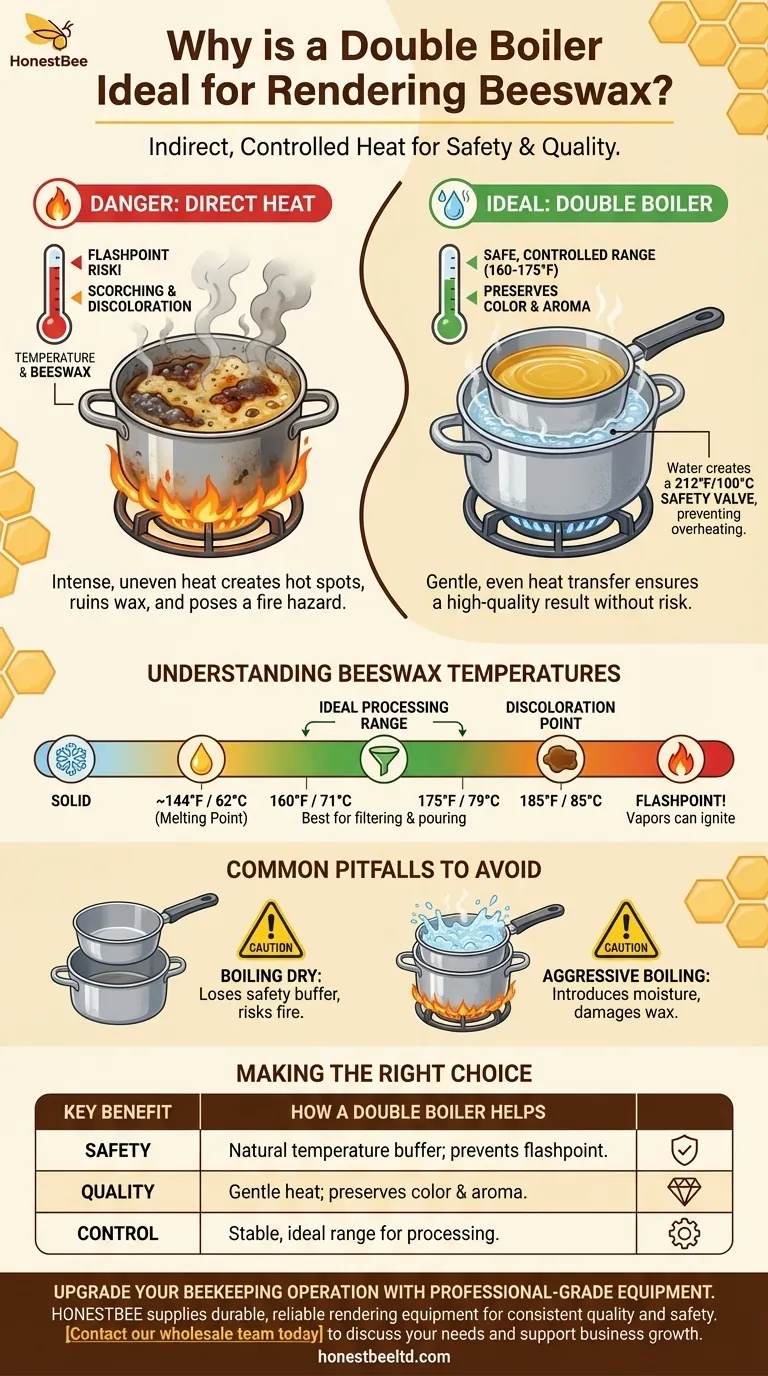

A double boiler is ideal for rendering beeswax because it uses indirect heat to melt the wax slowly and evenly. This method provides precise temperature control, which is essential for preventing the wax from scorching, discoloring, or dangerously reaching its flashpoint.

The core challenge of rendering beeswax is its low melting point combined with its flammability. A double boiler solves this by using simmering water as a natural temperature buffer, making it nearly impossible to overheat the wax and ensuring both a safe process and a high-quality result.

The Principle of Controlled, Indirect Heat

Working with beeswax is a game of temperature management. Direct heat from a stove burner is intense and uneven, creating hot spots that can easily ruin the wax or create a fire hazard. The double boiler elegantly sidesteps this entire problem.

How a Double Boiler Works

A double boiler consists of two pots stacked together. The bottom pot holds a small amount of water, and the top pot, which contains the beeswax, is heated by the steam generated from the simmering water below.

This setup ensures the top pot is never in direct contact with the heating element. The heat is transferred gently and uniformly, allowing the beeswax to melt without any risk of scorching.

The Critical Role of Water as a Safety Valve

Water is the key to the entire process. Since water boils at 212°F (100°C), it creates a natural temperature ceiling for the top pot.

As long as there is water in the bottom pot, the temperature of the melting wax will remain safely below this point, far from its danger zone.

Why Direct Heat is Unsafe

Placing a pot of beeswax directly on a burner is a significant risk. The temperature can rise uncontrollably and quickly exceed the wax's flashpoint, which is the temperature at which its vapors can ignite.

A double boiler eliminates this risk by keeping the temperature in a safe, predictable range.

Understanding Beeswax Temperatures

Knowing the key temperature thresholds is crucial for a successful rendering. A double boiler makes it easy to stay within the ideal window.

Melting Point: ~144°F (62°C)

This is the temperature at which beeswax begins to liquefy. A gentle simmer in the bottom pot of a double boiler is all that is needed to reach and maintain this temperature.

Ideal Processing Range: 160-175°F (71-79°C)

Once melted, keeping the wax in this range ensures it remains fully liquid for filtering and pouring. The references suggest not exceeding 170°F (77°C) to maintain optimal quality.

Discoloration Point: Above 185°F (85°C)

If beeswax gets too hot, it will begin to darken and can lose its desirable natural color and aroma. The gentle heat of a double boiler helps preserve the wax's pristine quality.

Common Pitfalls to Avoid

While the double boiler method is remarkably safe, a few simple mistakes can undermine its effectiveness.

Letting the Bottom Pot Boil Dry

This is the most critical error to avoid. If all the water in the bottom pot evaporates, you lose your temperature buffer. The setup effectively becomes a direct-heat scenario, reintroducing the risk of scorching and fire.

Always ensure the bottom pot has an adequate amount of water and check it periodically during a long rendering session.

Using Aggressively High Heat

There is no benefit to a rapid, rolling boil. A light simmer at a medium-low setting provides more than enough heat to melt the wax.

Overly aggressive boiling can cause water to splash into your beeswax, introducing moisture that can affect the quality of the final product.

Making the Right Choice for Your Goal

Using a double boiler isn't just a suggestion; it's a best practice rooted in the fundamental properties of beeswax.

- If your primary focus is safety: The double boiler is non-negotiable, as it is the simplest way to prevent the wax from ever approaching its dangerous flashpoint.

- If your primary focus is quality: The gentle, even heating prevents discoloration and scorching, preserving the natural color and aroma of your beeswax.

- If your primary focus is control and ease: This method creates a stable, low-temperature environment that melts wax effectively without requiring constant, stressful adjustments.

By understanding and applying the principle of indirect heat, you can render beeswax safely and achieve a perfect result every time.

Summary Table:

| Key Benefit | How a Double Boiler Helps |

|---|---|

| Safety | Uses water as a natural temperature buffer to prevent wax from reaching its flashpoint. |

| Quality | Provides gentle, even heat to prevent discoloration and preserve the wax's natural color and aroma. |

| Control | Maintains a stable, ideal processing temperature (160-175°F / 71-79°C) for easy filtering and pouring. |

Upgrade Your Beekeeping Operation with Professional-Grade Equipment

For commercial apiaries and distributors, consistent, high-quality wax rendering is key to product quality and operational safety. HONESTBEE supplies the durable, reliable beekeeping supplies and equipment you need to scale your production efficiently and safely.

Contact our wholesale team today to discuss your equipment needs and discover how we can support your business growth.

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

People Also Ask

- What are the steps for using a wax melter to melt beeswax? Master Safe, Efficient Beeswax Processing

- Can I melt beeswax in a wax melter? The Key to Safe, High-Quality Results

- How can you monitor the temperature of beeswax as it melts? Ensure Quality & Safety with Precise Control

- How long does the wax melting process typically take? A Guide to Safe & Efficient Melting

- What are the safety precautions when working with melted beeswax? Prevent Burns and Fire Hazards