Filtering honey is a crucial quality control step that transforms the raw product from the hive into a stable and appealing final product. It is primarily done to remove physical impurities such as wax particles, propolis, bee parts, and other hive debris that can negatively affect the honey's clarity, texture, and shelf life.

The core purpose of filtering extends beyond simple cleaning. It is a strategic decision that dictates the honey's final characteristics, balancing consumer appeal and marketability against the desire to preserve its raw, natural state.

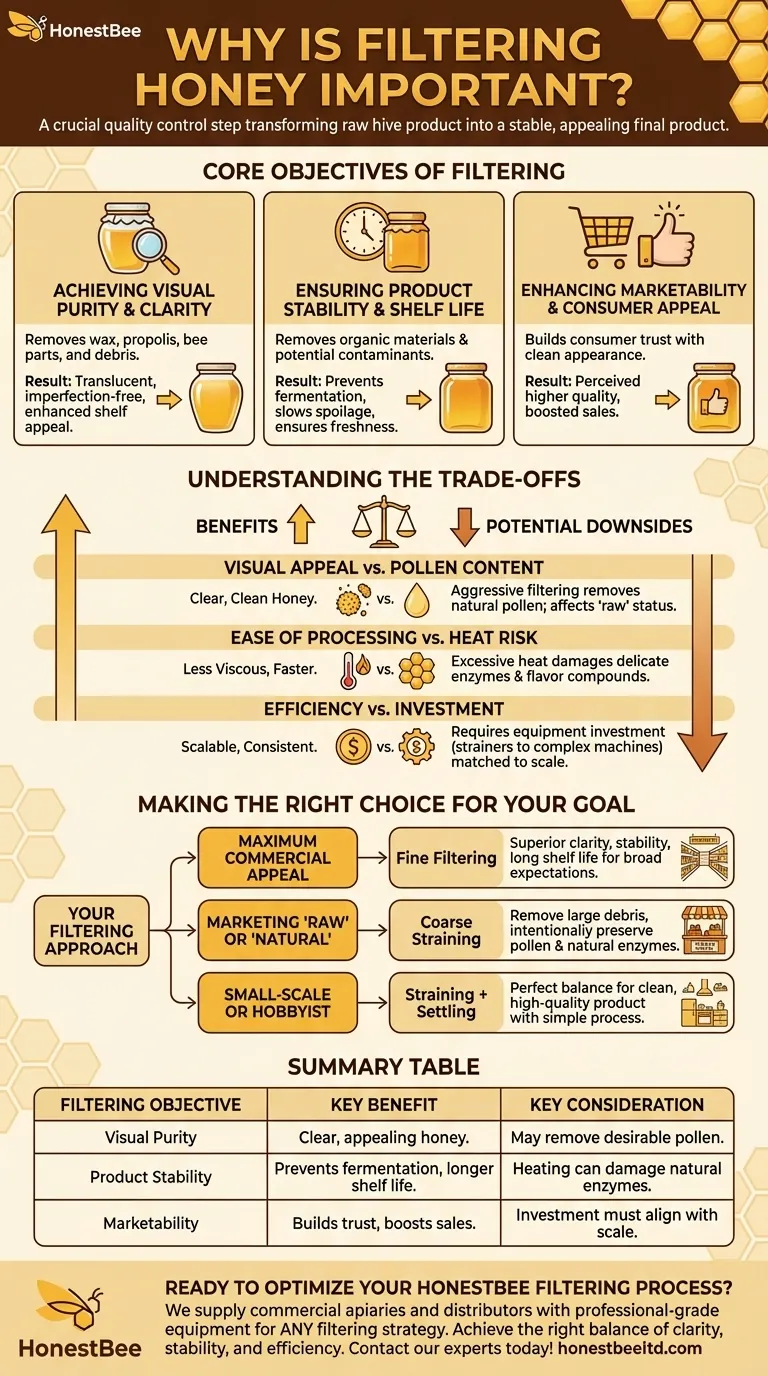

The Core Objectives of Filtering

Filtering is not a single action but a process with several distinct goals. Each objective contributes to the final quality and commercial viability of the honey.

Achieving Visual Purity and Clarity

Consumers often associate high-quality honey with a clear, golden, and visually pure appearance. Filtering is the most effective way to achieve this standard.

By removing suspended particles like beeswax, propolis, and other small debris, the honey becomes translucent and free from imperfections. This enhances its aesthetic appeal on the shelf.

Ensuring Product Stability and Shelf Life

Raw honey contains various organic materials that can act as nucleation points for crystallization or introduce yeast spores.

Filtering removes these potential contaminants, which helps prevent or slow down fermentation and spoilage. A cleaner product is a more stable product, ensuring it remains fresh and maintains its quality for a much longer period.

Enhancing Marketability and Consumer Appeal

A clear, clean, and professional-looking product builds consumer trust. Honey that is free of visible impurities is perceived as higher quality and safer to consume.

This improved appearance and extended shelf life directly boost marketability and sales, whether you are a small-scale beekeeper or a large commercial producer.

Understanding the Trade-offs of Filtering

While filtering provides significant benefits, it's essential to understand the potential downsides. The method and intensity of filtering involve critical trade-offs that affect the final product.

The Impact on Pollen Content

One of the most significant trade-offs involves pollen. Aggressive, fine filtering can remove much of the naturally occurring pollen from the honey.

Many consumers specifically seek out local honey for its pollen content, believing it offers regional health benefits. Therefore, marketing honey as "raw" or "unfiltered" often requires leaving this pollen intact, which necessitates only minimal straining.

The Risk of Introducing Heat

To make honey less viscous and easier to filter, commercial operations often heat it. However, this carries a significant risk.

Excessive heat can destroy the delicate enzymes and volatile aromatic compounds that give raw honey its unique flavor and perceived health benefits. Gentle or no-heat methods are preferable for preserving these natural properties.

Investment vs. Scale

Proper filtering requires an investment in equipment, from simple strainers for a hobbyist to more complex pumps and filtering machines for commercial operations.

The decision to invest must be balanced against the scale of your operation and your target market's expectations for the final product.

Making the Right Choice for Your Goal

Your approach to filtering should be a deliberate choice based on the product you want to create and the market you want to serve.

- If your primary focus is maximum commercial appeal: Fine filtering is necessary to achieve superior clarity, stability, and a long shelf life that meets broad consumer expectations.

- If your primary focus is marketing "raw" or "natural" honey: Use only coarse straining to remove large debris while intentionally preserving the pollen and natural enzymes.

- If your primary focus is small-scale or hobbyist production: A simple process of straining followed by a period of settling is often the perfect balance for producing a clean, high-quality product.

Ultimately, your filtering strategy is the critical link between the raw product from the hive and the finished product on the shelf.

Summary Table:

| Filtering Objective | Key Benefit | Key Consideration |

|---|---|---|

| Visual Purity | Removes wax, propolis & debris for clear, appealing honey. | Aggressive filtering may remove desirable pollen. |

| Product Stability | Prevents fermentation & spoilage for a longer shelf life. | Heating for easier filtering can damage natural enzymes. |

| Marketability | Builds consumer trust and boosts sales with a professional look. | Investment in equipment must align with production scale. |

Ready to optimize your honey filtering process for superior quality and market success?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the professional-grade, wholesale-focused supplies needed to implement the perfect filtering strategy—whether your goal is crystal-clear commercial appeal or preserving the raw qualities of natural honey. Our equipment helps you achieve the right balance of clarity, stability, and efficiency.

Contact our experts today to discuss the best filtering solutions for your operation and target market.

Visual Guide

Related Products

- Professional Honey Filter with Tripod Support Stand

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Professional Stainless Steel Honey Filter with Support Handle

- Two-Stage Plastic Honey Filter for Buckets

- Nylon Honey Strainer Square Filter Cloth for Honey Filters

People Also Ask

- What filter size for honey? A Beekeeper's Guide to Straining for Clarity and Quality

- What are the benefits of drying honey filtering equipment after use? Protect Your Honey Quality & Equipment Investment

- What is the primary purpose of honey filters? Achieve Professional Clarity & Pure Honey Quality

- Why is filtering honey considered an essential step in honey processing? Ensure Quality and Commercial Viability

- What is better, a 100 or 200 micron filter? Find the Right Fit for Your Water System