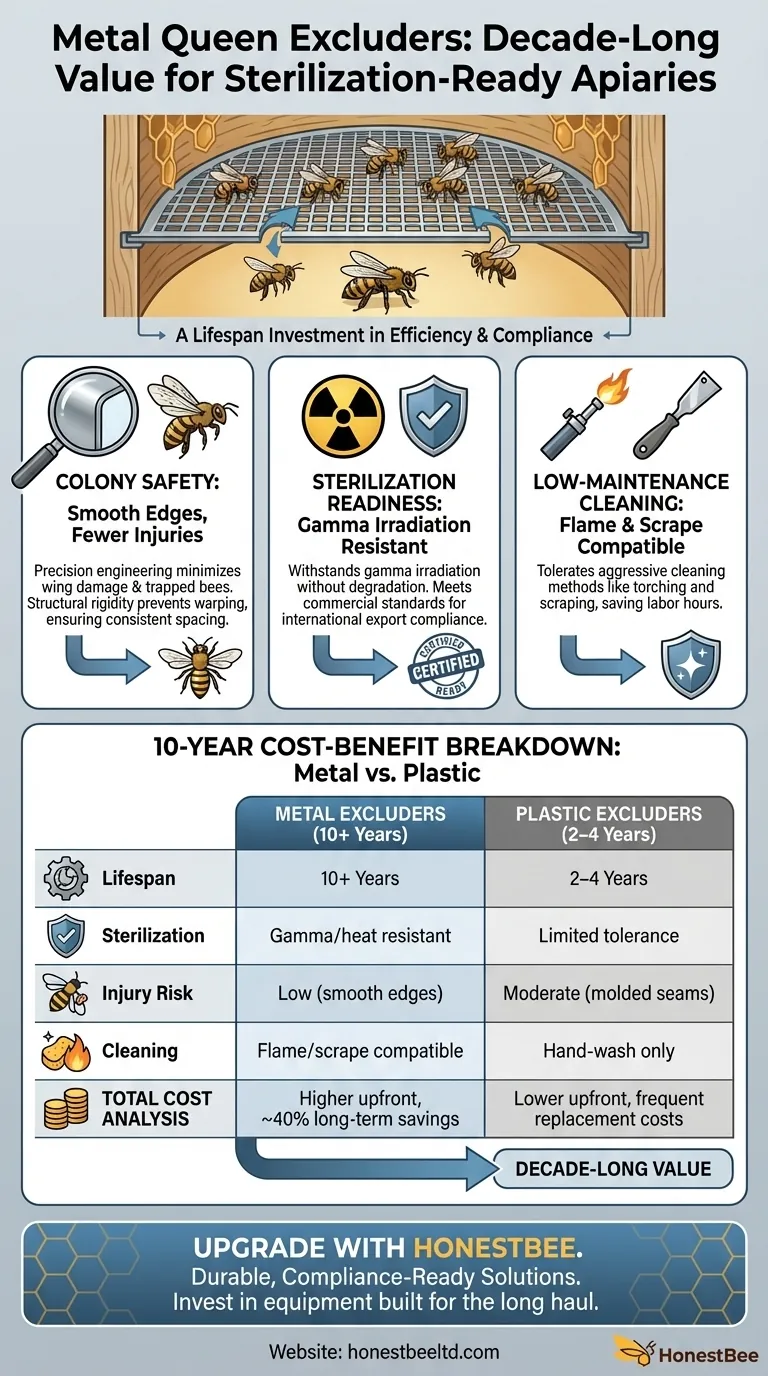

For commercial beekeepers, equipment choices directly impact operational efficiency and compliance. Metal queen excluders stand out as a lifespan investment—combining colony safety, sterilization readiness, and long-term cost savings. Here’s how they outperform alternatives.

Metal Queen Excluders: Beyond Basic Durability

How Smooth Edges and Structural Integrity Protect Your Colony

Metal excluders minimize bee injuries through precision engineering. Unlike plastic variants with molded seams, stainless steel or galvanized models feature rolled edges that prevent wing damage during worker bee passage. Beekeepers report fewer instances of trapped or injured bees—a critical factor for maintaining hive productivity.

Structural rigidity also prevents warping, a common issue with plastic excluders in high-heat environments. Warped excluders create uneven gaps, allowing queen bees to bypass the barrier and lay eggs in honey supers. Metal’s stability ensures consistent spacing year-round.

Gamma Irradiation Resistance: Meeting Commercial Beekeeping Standards

Commercial operations often require sterilization to prevent disease spread. Metal excluders withstand gamma irradiation—a standard sterilization method—without degradation. Plastic excluders may become brittle or discolored after repeated treatments, necessitating replacement.

Key advantage: Metal’s durability aligns with protocols for international honey exports, where sterilization is mandatory for compliance with phytosanitary regulations.

Heat and Scraping Cleaning: Minimizing Maintenance Labor and Costs

Metal excluders tolerate aggressive cleaning methods:

- Flame torching: Quickly eliminates wax buildup and pathogens.

- Scraping: Metal withstands blade scraping without gouging.

Plastic excluders risk melting or deformation under similar treatments, requiring gentler (and slower) cleaning. For large-scale apiaries, metal’s low-maintenance design translates to labor-hour savings.

Metal vs. Plastic: A 10-Year Cost-Benefit Breakdown for Beekeepers

| Factor | Metal Excluders | Plastic Excluders |

|---|---|---|

| Lifespan | 10+ years | 2–4 years |

| Sterilization | Gamma/heat resistant | Limited tolerance |

| Injury Risk | Low (smooth edges) | Moderate (molded seams) |

| Cleaning | Flame/scrape compatible | Hand-wash only |

Total cost analysis: While metal excluders cost 2–3× more upfront, their decade-long service life outweighs replacing plastic units every few years. For a 100-hive operation, metal can reduce long-term equipment costs by roughly 40%.

Upgrade to Sterilization-Ready Equipment with HONESTBEE

For commercial beekeepers and distributors, HONESTBEE’s metal queen excluders offer durable, compliance-ready solutions. Reduce replacement costs and hive disruptions—invest in equipment built for the long haul.

Have you evaluated how equipment longevity impacts your annual operational budget?

Visual Guide

Related Products

- Metal Queen Bee Excluder for Beekeeping

- Wooden Queen Bee Excluder for Beekeeping

- Premium Wood Framed Metal Wire Queen Bee Excluder

- Professional Plastic Queen Excluder for Modern Beekeeping

- Stainless Steel Beekeeping Queen Grafting Tool for Honey Bee Rearing

Related Articles

- Beyond Upfront Cost: Why Metal Queen Excluders Are an Investment in Apiary Efficiency

- How Queen Excluders Protect Honey Quality: Science, Economics & Best Practices

- The Ten-Year Gate: Why Your Queen Excluder Defines Your Apiary's Economics

- How to Choose the Right Queen Excluder for Your Beekeeping Success

- Metal Queen Excluders: The Long-Term Solution for Healthy, Productive Hives