Key Expectation Promise: This guide reveals the science behind honey’s corrosive effects on extractors, provides step-by-step cleaning protocols, and demonstrates how neglect accelerates equipment failure—helping you avoid unnecessary replacement costs.

Why Proper Honey Extractor Cleaning Matters

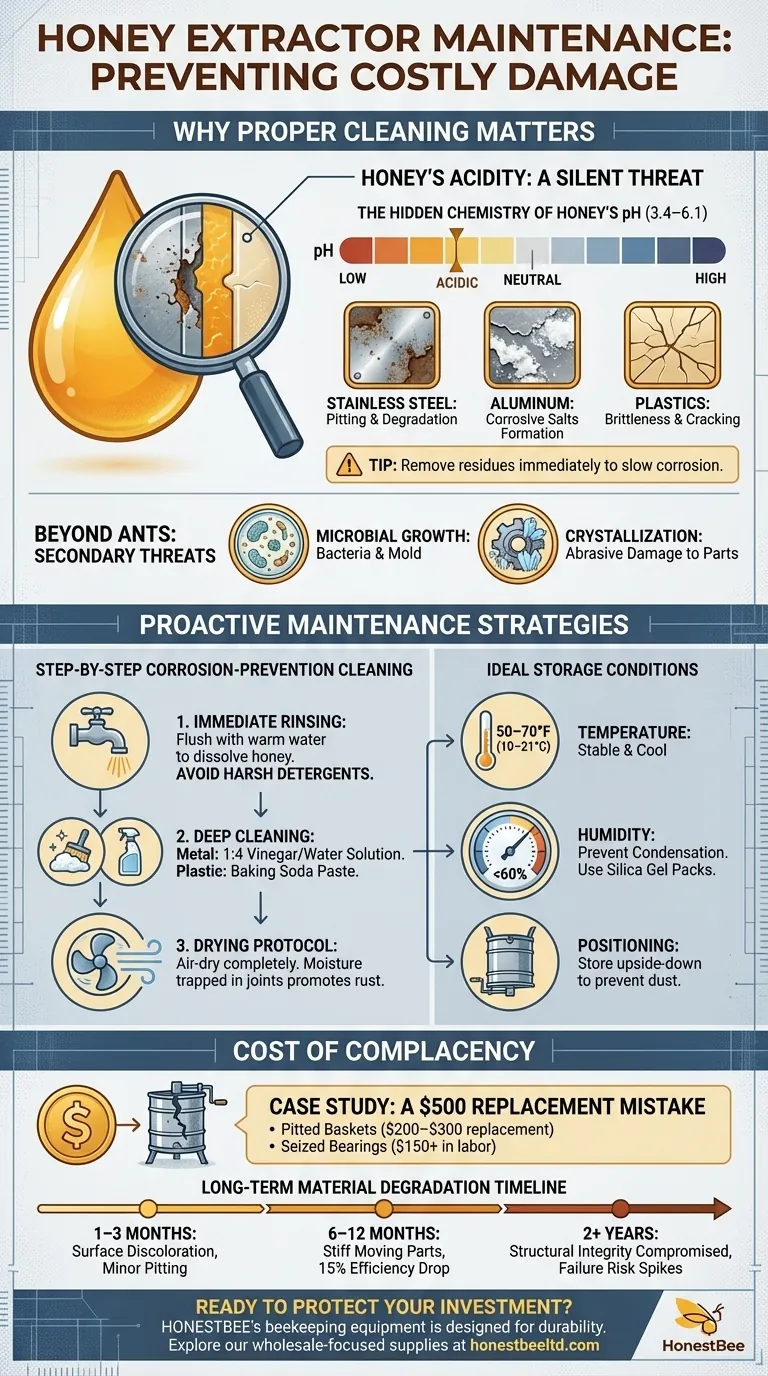

Honey’s natural composition makes it a stealthy threat to your extraction equipment. Left unchecked, residues trigger chemical reactions that degrade metal and plastic components over time.

The Hidden Chemistry of Honey’s Acidity

Research shows honey’s pH ranges from 3.4 to 6.1, placing it firmly in the acidic to mildly acidic category. This acidity reacts with:

- Stainless steel: Prolonged exposure can pit surfaces, especially in lower-grade alloys.

- Aluminum: Forms corrosive salts when combined with honey’s organic acids.

- Plastics: Certain polymers become brittle after repeated acidic contact.

Tip: After extraction, always prioritize removing honey residues—even small amounts accelerate corrosion.

Beyond Ants: Secondary Threats from Residue

Sticky residues attract more than pests. They create breeding grounds for:

- Microbial growth: Bacteria and mold thrive in sugary residues, contaminating future batches.

- Crystallization: Dried honey forms abrasive deposits that damage moving parts during operation.

Proactive Maintenance Strategies

Step-by-Step Corrosion-Prevention Cleaning

-

Immediate Rinsing

- Flush extractor with warm (not hot) water post-use to dissolve honey. Avoid harsh detergents that may leave chemical residues.

-

Deep Cleaning

- For metal parts: Use a diluted vinegar solution (1:4 vinegar-to-water ratio) to neutralize alkaline corrosion. Rinse thoroughly.

- For plastic components: Scrub with baking soda paste to gently remove residues without scratching.

-

Drying Protocol

- Air-dry all parts completely before reassembly. Moisture trapped in joints promotes rust.

Ideal Storage Conditions for Metal/Plastic Parts

- Temperature: Store in a stable, cool environment (50–70°F/10–21°C). Extreme heat warps plastics; cold contracts metal.

- Humidity: Maintain <60% humidity to prevent condensation. Silica gel packs in storage bins help control moisture.

- Positioning: Store extractors upside-down to prevent dust accumulation in hard-to-clean areas.

Cost of Complacency

Case Study: A Beekeeper’s $500 Replacement Mistake

A commercial apiary skipped routine cleaning for two seasons, assuming occasional rinses sufficed. Result:

- Pitted stainless steel baskets required replacement ($200–$300 per unit).

- Seized bearings from crystallized honey demanded full motor overhauls ($150+ in labor).

Long-Term Material Degradation Timeline

- 1–3 months: Surface discoloration appears; minor pitting begins.

- 6–12 months: Moving parts stiffen; efficiency drops by ~15%.

- 2+ years: Structural integrity compromised; failure risk spikes.

Ready to Protect Your Investment?

HONESTBEE’s beekeeping equipment is designed for durability—but even the best tools need care. Explore our wholesale-focused supplies to keep your operation running smoothly.

Reflective Close: How might a 10-minute cleaning routine today save you hundreds in repairs tomorrow?

Visual Guide

Related Products

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- HONESTBEE 6 Frame Three Use Electric Honey Extractor for Beekeeping

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

Related Articles

- The Physics of a Perfect Harvest: Why the Honey Extractor Is a Marvel of Efficiency

- Beyond the Harvest: The Critical Discipline of Cleaning Your Honey Extractor

- Ethical Honey Harvesting: Essential Tools and Techniques for Beekeepers

- How to Prevent Honey Extractor Failures: Balancing Loads and Choosing Durable Frames

- How to Clean Your Honey Extractor Safely Without Compromising Honey Quality