For beekeepers, honey supers represent both opportunity and risk—these critical hive components store surplus honey but can also harbor contaminants that compromise yield quality. This guide delivers science-backed protocols for super maintenance, harvesting best practices, and real-world strategies from professional apiaries to ensure your honey remains pure from hive to jar.

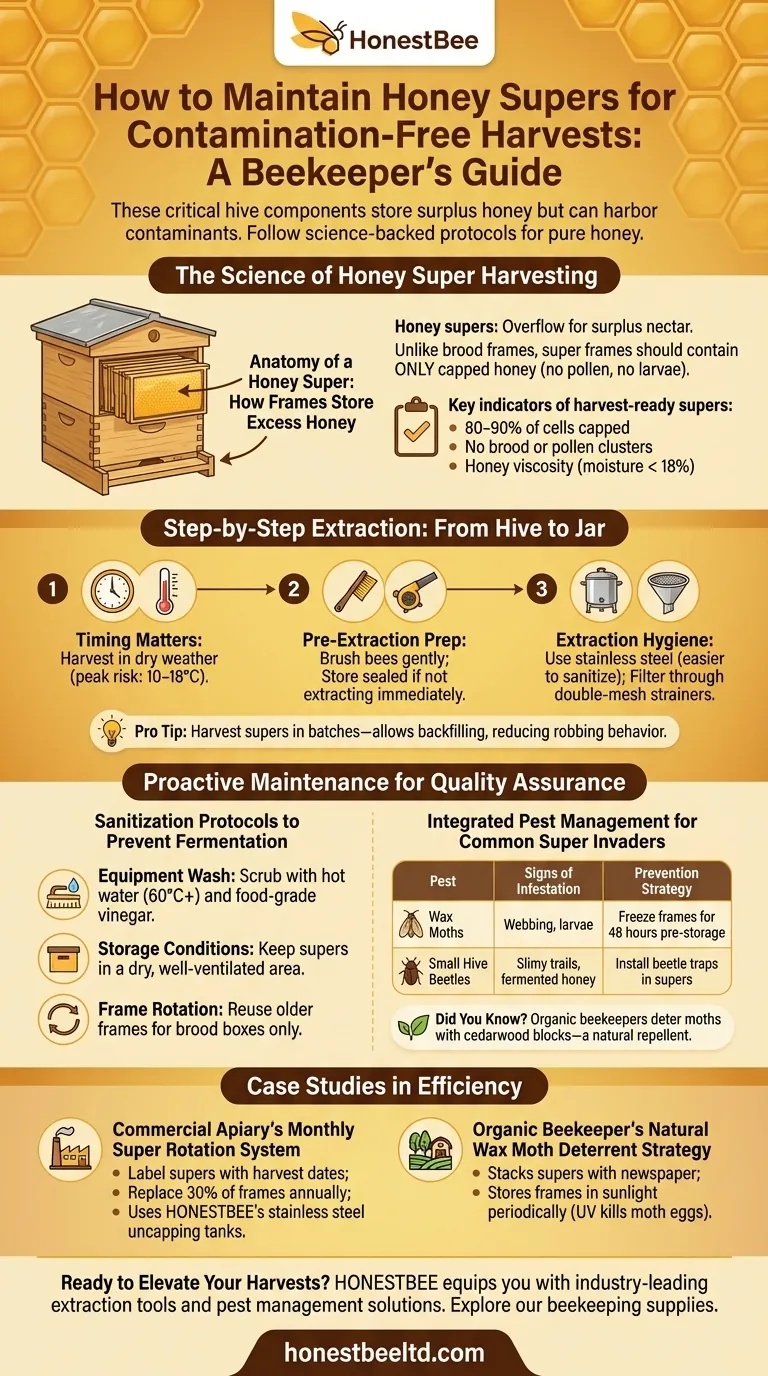

The Science of Honey Super Harvesting

Anatomy of a Honey Super: How Frames Store Excess Honey

Honey supers function as overflow chambers where worker bees deposit nectar once brood boxes reach capacity. Unlike brood frames, super frames should contain only capped honey—no pollen or larvae. Research shows that brood presence in supers triggers nurse bees to remain indefinitely, increasing contamination risks.

Key indicators of harvest-ready supers:

- 80–90% of cells capped (uncapped honey ferments faster)

- No brood or pollen clusters

- Honey viscosity tested via refractometer (optimal moisture: under 18%)

Step-by-Step Extraction: From Hive to Jar

- Timing Matters: Harvest during dry weather; humidity accelerates crystallization (peak risk: 10–18°C).

- Pre-Extraction Prep:

- Brush bees gently off frames using a bee brush or air blower.

- Store supers in a sealed, pest-proof space if not extracting immediately.

- Extraction Hygiene:

- Use stainless steel equipment (easier to sanitize than wood).

- Filter raw honey through double-mesh strainers to remove wax debris.

Pro Tip: Harvest supers in batches—this allows bees to backfill emptied frames, reducing robbing behavior.

Proactive Maintenance for Quality Assurance

Sanitization Protocols to Prevent Fermentation

Contaminated extraction tools are a leading cause of spoiled honey. Implement these steps post-harvest:

- Equipment Wash: Scrub all surfaces with hot water (60°C+) and food-grade vinegar.

- Storage Conditions: Keep supers in a dry, well-ventilated area; moisture encourages mold.

- Frame Rotation: Reuse older frames for brood boxes only—their porous wax absorbs bacteria over time.

Integrated Pest Management for Common Super Invaders

| Pest | Signs of Infestation | Prevention Strategy |

|---|---|---|

| Wax Moths | Webbing, larvae in comb | Freeze frames for 48 hours pre-storage |

| Small Hive Beetles | Slimy trails, fermented honey | Install beetle traps in supers |

Did You Know? Organic beekeepers deter moths with cedarwood blocks—a natural repellent that doesn’t taint honey.

Case Studies in Efficiency

Commercial Apiary’s Monthly Super Rotation System

A 500-hive operation in Florida maintains yield consistency by:

- Labeling supers with harvest dates to track age.

- Replacing 30% of frames annually to minimize pathogen buildup.

- Using HONESTBEE’s stainless steel uncapping tanks for faster, cleaner processing.

Organic Beekeeper’s Natural Wax Moth Deterrent Strategy

A Vermont beekeeper avoids chemicals by:

- Stacking supers with newspaper between layers (moths dislike the ink smell).

- Storing frames in sunlight periodically—UV light kills moth eggs.

Ready to Elevate Your Harvests?

HONESTBEE equips commercial beekeepers and distributors with industry-leading extraction tools and pest management solutions—all designed to protect your honey’s purity and profitability. Explore our beekeeping supplies to build a contamination-resistant workflow today.

Final Thought: The difference between good and great honey lies not just in floral sources, but in the invisible diligence of super maintenance. By adopting these protocols, you’re safeguarding nature’s liquid gold at every step.

Visual Guide

Related Products

- Plastic Queen Bee Excluder for Bee Hive Wholesale

- In-Hive Dual Compartment Frame Bee Feeder for Targeted Colony Nutrition

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- Wooden Bee Brush with Double-Row Horsehair Bristles

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

Related Articles

- How to Choose the Best Queen Excluder: Balancing Durability, Cost, and Bee Welfare

- Queen Excluders: Strategic Tool or Barrier to Natural Beekeeping?

- Beyond the Gate: The Queen Excluder as a Keystone of Apiary Efficiency

- The Geometry of Order: Why the Queen Excluder is a Beekeeper's Most Strategic Tool

- The Fatal Logic of the Winter Cluster: Why a Queen Excluder Becomes a Hive's Single Point of Failure