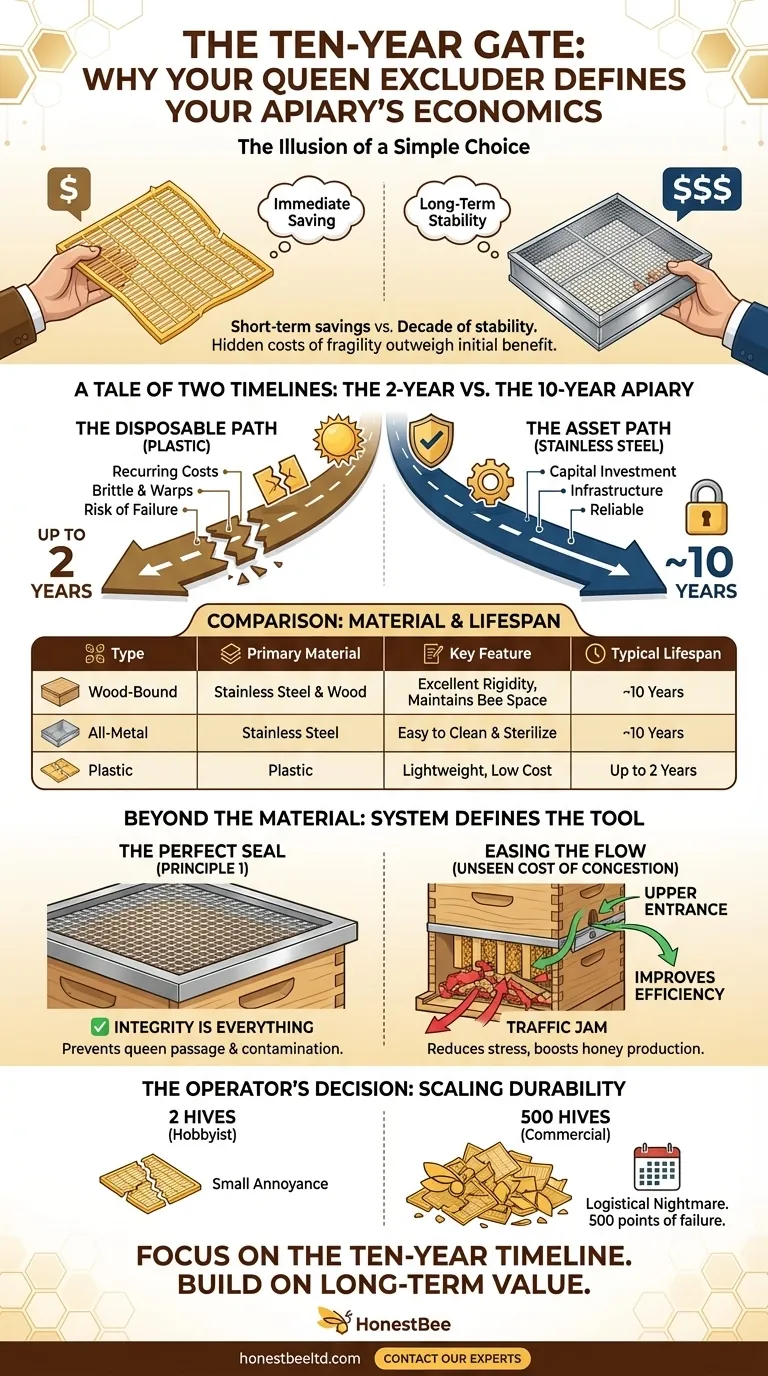

The Illusion of a Simple Choice

An apiary manager stands before a choice. In one hand, a lightweight plastic queen excluder, costing a few dollars. In the other, a rigid stainless steel model, costing four times as much.

On the surface, it’s a simple calculation of upfront cost. But this decision isn't about saving a few dollars today. It's a psychological test of time horizons. It reveals whether you are managing for this season's expenses or for the next decade's operational stability.

The cheaper option feels like a win. Our minds are wired to favor immediate, tangible savings. Yet, in systems like beekeeping, the hidden costs of fragility almost always outweigh the initial benefit.

A Tale of Two Timelines: The 2-Year vs. The 10-Year Apiary

The choice of material isn't just a detail; it sets the operational rhythm for your entire apiary. You are choosing between a disposable component and a permanent asset.

The Disposable Path: The Plastic Excluder

Plastic excluders are wonderfully economical. They are light and easy to handle. For a new beekeeper or a small-scale experiment, they represent a low barrier to entry.

But for a commercial operation, they introduce a cycle of recurring costs. With a maximum lifespan of two years, they become brittle in the sun and warp under the hive's weight and heat. This isn't a one-time purchase; it's a subscription you pay in money, labor, and the constant risk of failure during a critical nectar flow.

The Asset Path: The Stainless Steel Excluder

Stainless steel excluders, whether all-metal or wood-bound, are a different class of tool. They are a capital investment designed to last for a decade.

- Wood-Bound Steel: Offers excellent rigidity and perfectly maintains the critical bee space above the brood frames.

- All-Metal Steel: Incredibly durable and the easiest to clean and sterilize, preventing disease transfer between hives.

The higher upfront cost vanishes when amortized over ten years of flawless service. This isn't an expense; it's infrastructure. It's the gate that reliably separates pure honey from the brood nest, season after season.

| Type | Primary Material | Key Feature | Typical Lifespan |

|---|---|---|---|

| Wood-Bound | Stainless Steel & Wood | Excellent rigidity, maintains bee space | ~10 years |

| All-Metal | Stainless Steel | Easy to clean and sterilize | ~10 years |

| Plastic | Plastic | Lightweight, flexible, low cost | Up to 2 years |

Beyond the Material: The System Defines the Tool

The most brilliant engineers understand that the performance of any single component is defined by the system it operates within. A queen excluder is not just a screen; it's an interface that governs hive traffic, honey purity, and colony health.

The First Principle: A Perfect Seal

A warped plastic excluder or a bent metal one can create a small gap along the edge. To an accountant, it's a minor defect. To a beekeeper, it is a total system failure.

If the queen slips through that gap into the honey supers, she will begin laying eggs. This contaminates the harvest, creates immense work to find and relocate her, and defeats the entire purpose of the device. The integrity of the seal is everything.

Easing the Flow: The Unseen Cost of Congestion

Forcing tens of thousands of worker bees through a single barrier creates a traffic jam. This congestion can slow down honey production and cause physical wear on the bees' wings.

A best practice for high-production hives is to provide a small upper entrance above the excluder. This simple modification allows foragers to bypass the bottleneck, improving efficiency and reducing stress on the colony. The tool works best when its impact on the larger system is understood and mitigated.

The Operator's Decision: Scaling Durability

For a hobbyist with two hives, replacing a cracked plastic excluder is a small annoyance.

For a commercial apiary with 500 hives, replacing 500 brittle excluders every other year is a logistical and financial nightmare. It’s 500 points of potential failure. The decision to invest in durable, reliable equipment is a hallmark of a professional operation that values its time and labor.

This is the principle we build on at HONESTBEE. We focus on supplying commercial apiaries and equipment distributors with tools designed for the ten-year timeline, not the two-year replacement cycle. For distributors, offering equipment that lasts builds a reputation for quality and earns customer loyalty. For apiaries, it provides a foundation for predictable, scalable success.

The true cost of a tool is not its price tag. It's the sum of its purchase price, its replacement frequency, the labor it consumes, and the cost of its failure at a critical moment.

For operations built on the principle of long-term value, choosing the right supply partner is as crucial as choosing the right tool. Contact Our Experts

Visual Guide

Related Products

- Professional Plastic Queen Excluder for Modern Beekeeping

- Premium Wood Framed Metal Wire Queen Bee Excluder

- High Performance Plastic Queen Excluder for Beekeeping and Apiary Management

- Wooden Queen Bee Excluder for Beekeeping

- Metal Queen Bee Excluder for Beekeeping

Related Articles

- Why Plastic Queen Excluders Outperform Metal and Wood: Science, Savings, and Hive Protection

- How to Choose Queen Excluder Materials for Healthier Hives and Higher Yields

- The Geometry of Order: Why the Queen Excluder is a Beekeeper's Most Strategic Tool

- The Unseen Gatekeeper: Why Queen Excluders Are Non-Negotiable for Flow Hives

- Plastic Queen Excluders vs. Alternatives: A Beekeeper’s Guide to Smarter Hive Management