The Invisible Architecture of the Hive

A beekeeper hefts a pry bar, straining to separate two hive boxes. They don't budge. They are welded together with a matrix of hardened resin and wax. When they finally crack apart with a violent jolt, the air fills with angry bees.

This frustrating scene isn't a sign of a strong hive. It's a symptom of a fundamental design failure.

The modern beehive is not just a wooden box; it's a meticulously engineered system governed by a single, non-negotiable principle. Understanding this principle is far more important than memorizing dimensions, because it dictates the behavior of the colony and the sanity of the beekeeper.

This principle is called "bee space."

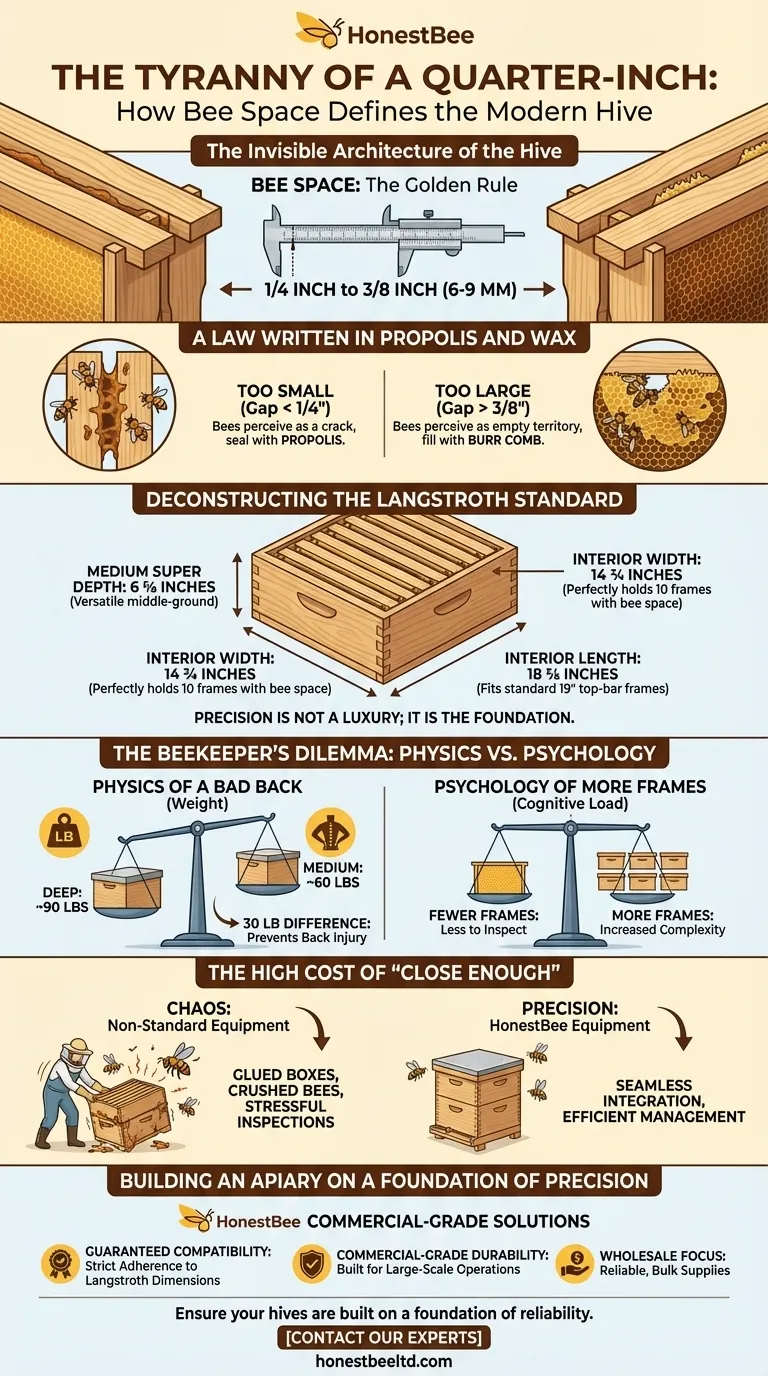

A Law Written in Propolis and Wax

Bee space is the gap bees naturally leave open as a passageway, roughly ¼ to ⅜ of an inch (6-9 mm). It is a behavioral trigger. It is a law of hive physics.

Violate this law, and the bees will correct your mistake.

- If a space is too small, they perceive it as a crack and seal it with propolis, a hard, sticky resin.

- If a space is too large, they perceive it as empty territory and build burr comb to fill it.

The result is the same: components become glued together, frames are immovable, and simple inspections descend into chaos. The hive becomes a fortress, not just against predators, but against its keeper.

Deconstructing the Langstroth Standard

The standard Langstroth hive is a masterclass in applied biology. Every dimension is a direct response to the law of bee space. Let's look at the versatile medium super as an example.

The Core Dimensions: A System of Precision

A 10-frame medium box isn't just a container; it's a precisely defined volume designed for bee movement and modularity.

| Dimension | Measurement | Purpose |

|---|---|---|

| Depth | 6 ⅝ inches | The defining feature; a versatile middle-ground for honey or brood. |

| Interior Width | 14 ¾ inches | Perfectly holds 10 frames while maintaining bee space between them. |

| Interior Length | 18 ⅜ inches | Ensures standard 19-inch top-bar frames fit with correct spacing. |

These numbers are not suggestions. They are the specifications for a predictable, manageable system. Choosing between an 8-frame system (which has a narrower width of ~12 ¼ inches) and a 10-frame system is less important than choosing one and sticking with it. The two are not compatible.

The Beekeeper's Dilemma: Physics vs. Psychology

The choice of equipment has profound consequences for the person managing the hive. The medium box offers a compelling compromise in a game of physical and psychological trade-offs.

The Physics of a Bad Back

The single greatest argument for the medium box is weight.

- A deep hive body full of honey can weigh over 90 pounds (40 kg).

- A medium super full of honey weighs a more manageable 50-60 pounds (22-27 kg).

That 30-pound difference isn't just a number. It's the difference between a sustainable career and a debilitating back injury. For this reason, many commercial operations run "all-medium" hives, using them for both brood chambers and honey supers.

The Psychology of More Frames

The trade-off for lighter lifts is a higher cognitive load. An all-medium hive requires more boxes to achieve the same volume as a deep brood chamber.

This means more boxes to unstack and more frames to pull during an inspection. It's a choice between acute physical strain (lifting heavy deeps) and prolonged operational complexity (inspecting more frames). There is no universally correct answer, only the right answer for your body and your management style.

The High Cost of "Close Enough"

In a system defined by quarter-inch tolerances, "close enough" is a recipe for failure. Using non-standard or inconsistently manufactured equipment is one of the most expensive mistakes an apiary can make.

It introduces systemic chaos. Bee space is violated. Boxes are glued shut with propolis. Burr comb connects frames, leading to crushed bees and a defensive colony when you try to separate them. Inspections become slow, stressful, and destructive.

Precision is not a luxury; it is the foundation of efficient, scalable, and humane beekeeping. Without it, you are not managing bees; you are fighting your own equipment.

Building an Apiary on a Foundation of Precision

For commercial apiaries and equipment distributors, standardization isn't just a goal—it's an operational necessity. Every component must integrate seamlessly, season after season. This is where professional-grade equipment becomes a non-negotiable asset.

HONESTBEE supplies commercial-grade beekeeping equipment built on the principle of absolute precision.

- Guaranteed Compatibility: Our hive bodies, supers, and frames adhere strictly to industry-standard Langstroth dimensions. They respect bee space, ensuring they integrate perfectly with your existing equipment.

- Commercial-Grade Durability: We build equipment designed to withstand the rigors of large-scale operations, protecting your investment for years to come.

- Wholesale Focus: Our operations are streamlined to provide reliable, bulk supplies that keep your apiary running efficiently.

To ensure your hives are built on a foundation of reliability and precision, let's discuss your operational needs. Contact Our Experts

Visual Guide

Related Products

- Langstroth Bee Hives Bee Keeping Box for Beginners Beekeeping

- Multi-Function Plier-Style Frame Grip Hive Tool

- HONESTBEE Professional Multi-Functional Hive Tool with Ergonomic Wood Handle

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

Related Articles

- The Unseen Architecture: Why Your Hive Size Defines Your Apiary's Future

- The Essential Guide to Beehive Boxes: Maximizing Colony Health and Productivity

- How to Choose Between Top Bar and Langstroth Hives for Effortless Beekeeping

- How Medium Boxes Elevate Beekeeping Efficiency: Ergonomics, Hive Health & Cost Savings

- Comprehensive Guide to Attracting Bees to a Hive