To remove pollen from honey, the industry standard is a process called ultrafiltration. This method pushes honey, often heated to reduce its viscosity, through microscopic filters that are fine enough to capture tiny pollen grains. However, this is distinct from simple straining, which only removes larger visible impurities like wax or bee parts while leaving the beneficial pollen intact.

The question isn't just how to remove pollen, but why it's there in the first place. While filtration can create a clearer product, it strips honey of the very elements that prove its origin and give it a unique identity.

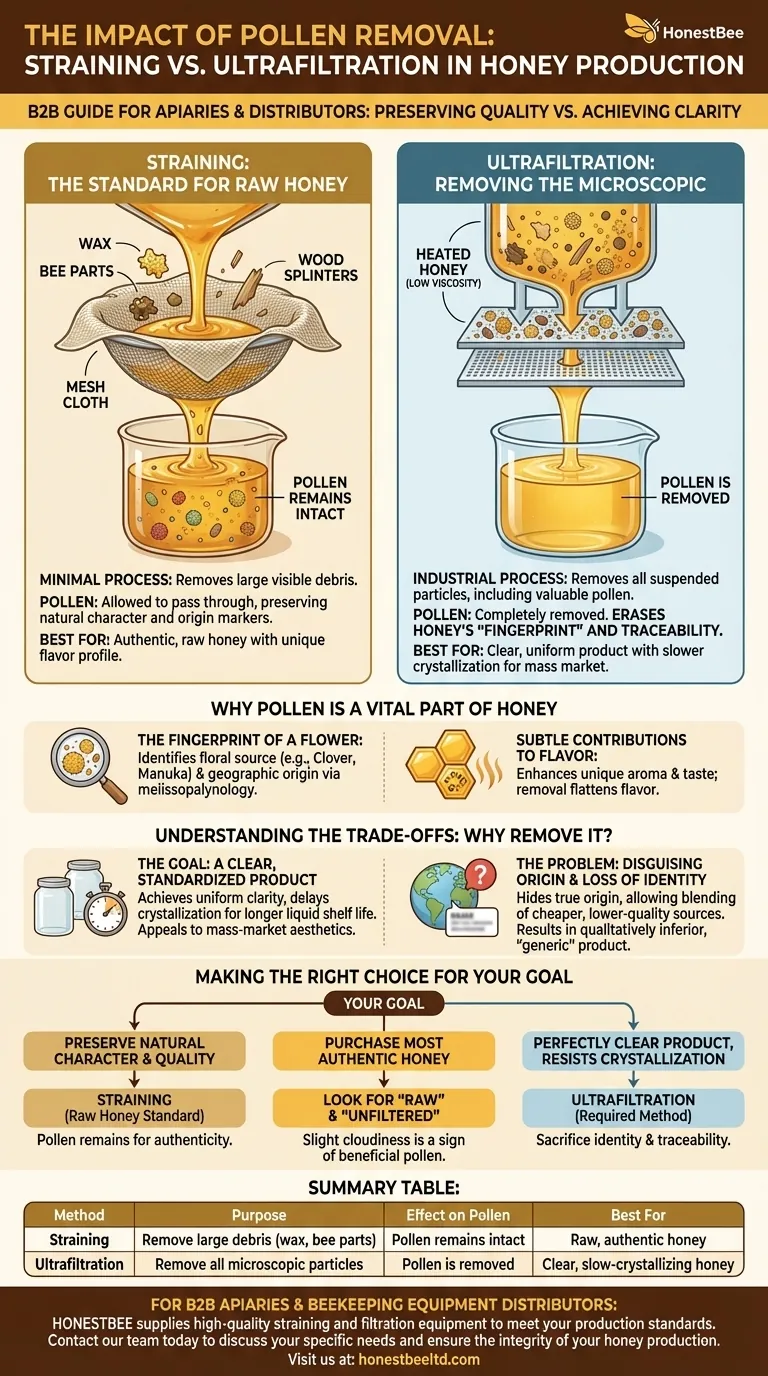

Straining vs. Filtering: A Critical Distinction

The method used to clean honey has a profound impact on the final product. The choice between straining and filtering determines whether the honey retains its natural character or becomes a more processed, generic sweetener.

Straining: The Standard for Raw Honey

Straining is a minimal process. It involves passing honey through a mesh or cloth to remove large, visible debris that is undesirable for consumption.

This includes things like bits of beeswax, wood splinters from the hive, or bee parts. Straining is a necessary step for all honey, but its key feature is that the mesh is large enough to allow microscopic pollen grains to pass through.

Ultrafiltration: Removing the Microscopic

Ultrafiltration is an industrial process designed to remove everything but the sugar and water. It is far more aggressive than simple straining.

To work effectively, honey is often heated to make it more fluid, and then forced under high pressure through extremely fine filters. This process removes all suspended particles, including the valuable pollen.

Why Pollen is a Vital Part of Honey

Pollen is not an impurity. It is an unavoidable and essential component of authentic honey, offering clear markers of its quality and origin.

The Fingerprint of a Flower

Pollen granules are the botanical fingerprint of honey. Experts in a field called melissopalynology can analyze the pollen in a honey sample to identify the exact types of flowers the bees foraged from.

This analysis definitively proves the honey's floral source (e.g., Clover, Manuka, Orange Blossom) and its geographic origin. Without pollen, the honey's identity is untraceable.

Subtle Contributions to Flavor

While the nectar itself is the primary source of flavor, the pollen contributes to the unique and subtle flavor and aroma profile of each honey varietal.

Removing the pollen can subtly flatten the taste, moving it closer to a generic sweet syrup.

Understanding the Trade-offs

If pollen is so valuable, why would anyone remove it? The reasons are rooted in industrial production and consumer aesthetics, not in creating a higher-quality product.

The Goal: A Clear, Standardized Product

Many large-scale honey producers use ultrafiltration to achieve a perfectly clear, uniform product. Filtered honey is visually clean and crystallizes much more slowly, giving it a longer shelf life as a liquid.

This appeals to a mass-market consumer who may mistakenly see cloudiness or crystallization as a defect.

The Problem: Disguising Origin

Because ultrafiltration erases honey's "fingerprint," it can be used to hide the true origin of the product.

Unscrupulous producers can blend cheap, low-quality honey from various international sources and pass it off as a premium local product. By removing the pollen, they remove the evidence of this blending.

The Loss of Identity

Ultimately, filtering trades authenticity for aesthetics. The process removes the very components that make a specific honey unique and traceable, resulting in a product that is cleaner-looking but nutritionally and qualitatively inferior.

Making the Right Choice for Your Goal

Your approach should depend entirely on what you want to achieve with the honey.

- If your primary focus is preserving natural character and quality: Use simple straining to remove debris. Never filter out the pollen, as it is a mark of authentic, raw honey.

- If your primary focus is purchasing the most authentic honey: Look for terms like "raw" and "unfiltered." A slight cloudiness is not a flaw—it's a sign that the beneficial pollen is still present.

- If your primary focus is a perfectly clear product that resists crystallization: Ultrafiltration is the required method, but understand you are sacrificing the honey's unique identity and traceability.

Choosing to keep the pollen is choosing to preserve the story and integrity of the honey itself.

Summary Table:

| Method | Purpose | Effect on Pollen | Best For |

|---|---|---|---|

| Straining | Remove large debris (wax, bee parts) | Pollen remains intact | Raw, authentic honey |

| Ultrafiltration | Remove all microscopic particles | Pollen is removed | Clear, slow-crystallizing honey |

For commercial apiaries and beekeeping equipment distributors: HONESTBEE supplies the high-quality straining and filtration equipment you need to process honey according to your quality standards. Whether you aim to produce authentic raw honey or a clear, stable product, our wholesale-focused operations provide reliable beekeeping supplies and equipment. Contact our team today to discuss your specific needs and ensure the integrity of your honey production.

Visual Guide

Related Products

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Professional Thermostatic Conical Honey Melter

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

People Also Ask

- What principle does the honey vacuum thickener use to concentrate honey? Preserve Quality with Low-Temperature Evaporation

- How does a honey dryer remove moisture from honey? Achieve Perfect Honey Stability with Controlled Drying

- How does the internal ventilation management of a beehive affect the efficiency of honey dehydration?

- Why is the use of dry sieves and storage containers critical? Prevent Honey Fermentation and Spoilage

- What are the processing advantages of using industrial dehumidification equipment for high-moisture tropical honey?