At its core, a centrifuge honey extractor operates on a simple, powerful principle: it uses centrifugal force to spin honey out of the comb. Frames of uncapped honeycomb are placed inside a large drum containing a rotating basket. As the basket spins at high speed, the honey is flung outward against the inner wall of the drum, separating cleanly from the wax comb and collecting at the bottom to be drained.

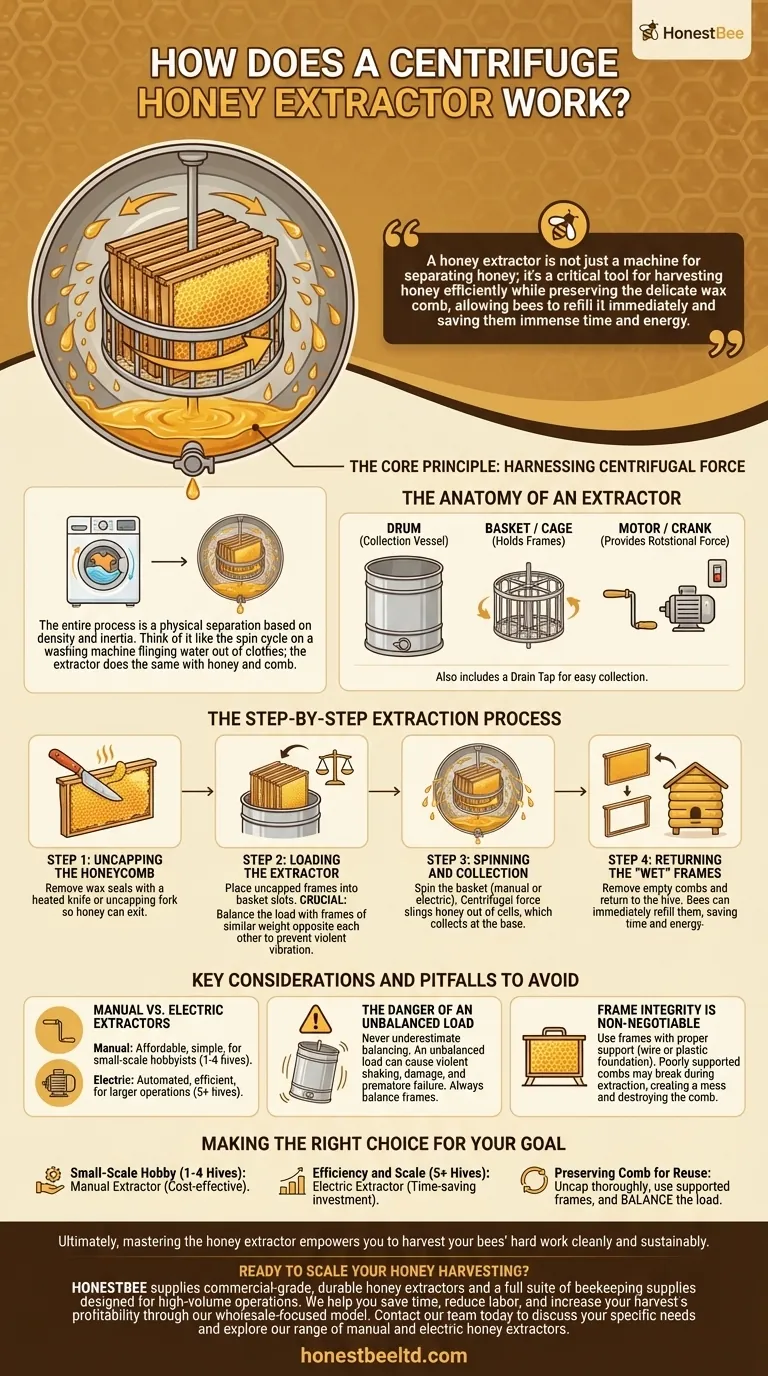

A honey extractor is not just a machine for separating honey; it's a critical tool for harvesting honey efficiently while preserving the delicate wax comb, allowing bees to refill it immediately and saving them immense time and energy.

The Core Principle: Harnessing Centrifugal Force

The entire process is a physical separation based on density and inertia. Think of it like the spin cycle on a washing machine flinging water out of clothes; the extractor does the same with honey and comb.

The Anatomy of an Extractor

An extractor consists of three main parts. A large cylindrical drum acts as the collection vessel. Inside, a basket or cage assembly holds the honey frames. This basket is connected to a central rod that is spun either by a hand crank (manual extractor) or an electric motor.

The Physics of Separation

When the frames spin, the honey, which is much denser than the wax comb, is forced outward. It travels out of the open cells and hits the interior wall of the drum. Gravity then takes over, causing the liquid honey to slide down the wall and pool at the bottom, where it can be drained through a tap or gate.

The Step-by-Step Extraction Process

Successfully extracting honey is a systematic process. Rushing or skipping a step can lead to lower yields or damaged equipment.

Step 1: Uncapping the Honeycomb

Before extraction, you must remove the thin layer of wax that bees use to cap and seal the honey cells. This is done with a specialized heated knife or an uncapping fork. If the cells remain capped, the honey has no way to exit during the spinning process.

Step 2: Loading the Extractor

The uncapped frames are placed vertically into the slots of the extractor's basket. It is crucial to balance the load by placing frames of similar weight opposite each other. An unbalanced extractor will vibrate violently, potentially damaging the machine, the frames, or both.

Step 3: Spinning and Collection

The spinning begins. With manual extractors, you control the speed with a hand crank. With electric models, you simply flip a switch. The centrifugal force slings the honey out of the cells. The honey collects at the base of the drum for harvesting.

Step 4: Returning the "Wet" Frames

After the honey is extracted, the now-empty combs (often called "wet" frames) are removed. A key benefit of this method is that these combs are still intact. They can be returned directly to the hive, giving the bees a massive head start on the next honey flow, as they don't have to spend energy rebuilding all the wax.

Key Considerations and Pitfalls to Avoid

While the principle is simple, practical application requires attention to detail to ensure safety and efficiency.

Manual vs. Electric Extractors

A manual extractor is powered by a hand crank. It is more affordable and simpler, making it ideal for hobbyists with only a few hives. An electric extractor uses a motor to automate the spinning, drastically reducing physical labor and increasing efficiency for larger operations.

The Danger of an Unbalanced Load

Never underestimate the importance of balancing your frames. An unbalanced load at high speed can cause the extractor to "walk" across the floor, shake violently, and put extreme stress on its components, leading to premature failure. Always load frames of similar weight opposite each other.

Frame Integrity is Non-Negotiable

Centrifugal force is powerful. Only use frames that have proper support, such as wire or plastic foundation. Foundationless or poorly supported combs are very likely to break apart during extraction, creating a sticky mess and destroying the comb you intended to preserve.

Making the Right Choice for Your Goal

Your choice and process depend entirely on the scale of your beekeeping operation and your primary objective.

- If your primary focus is a small-scale hobby (1-4 hives): A simple, manual extractor is a cost-effective and perfectly suitable tool for your needs.

- If your primary focus is efficiency and scale (5+ hives): An electric extractor is a necessary investment that will save you significant time and physical effort.

- If your primary focus is preserving your comb for reuse: Always uncap thoroughly, use well-supported frames, and balance the load in the extractor, regardless of which type you use.

Ultimately, mastering the honey extractor empowers you to harvest your bees' hard work cleanly and sustainably.

Summary Table:

| Key Component | Function |

|---|---|

| Drum | Acts as the collection vessel for the extracted honey. |

| Basket/Cage | Holds the uncapped honey frames securely during spinning. |

| Motor/Crank | Provides the rotational force (manual or electric). |

| Drain Tap | Allows for easy collection of honey from the bottom of the drum. |

| Critical Step | Why It Matters |

|---|---|

| Uncapping | Removes wax seals so honey can be flung from the cells. |

| Balancing Load | Prevents violent shaking and potential damage to the extractor. |

| Controlled Spinning | Uses centrifugal force to separate honey from the intact comb. |

| Returning Wet Frames | Saves bees time and energy by allowing them to refill existing comb. |

Ready to Scale Your Honey Harvesting?

Whether you're a commercial apiary looking to maximize yield or a distributor seeking reliable equipment for your customers, the right extractor is key to efficient, comb-preserving honey production.

HONESTBEE supplies commercial-grade, durable honey extractors and a full suite of beekeeping supplies designed for high-volume operations. We help you save time, reduce labor, and increase your harvest's profitability through our wholesale-focused model.

Contact our team today to discuss your specific needs and explore our range of manual and electric honey extractors.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

People Also Ask

- What are the equipment requirements for honey extraction? Key Differences for Migratory vs. Fixed Beekeeping

- How does a manual honey extractor function? Simple & Cost-Effective Honey Harvesting Guide

- What types of beekeepers are manual honey extractors best suited for? Ideal for Hobbyists & Small-Scale Apiaries

- What is the function of a honey extractor? Maximize Yield while Preserving Your Hive's Valuable Wax Combs

- How does industrial-grade honey extraction machinery facilitate the collection of monofloral honey? Boost Your Yields

- What are common problems with honey extractors and how can they be fixed? Ensure a Smooth Harvest Every Time

- What is a honey extractor and how does it work? Maximize Your Honey Harvest

- What is the function of geared motors in honey extractors? Automate Extraction for Maximum Efficiency and Volume