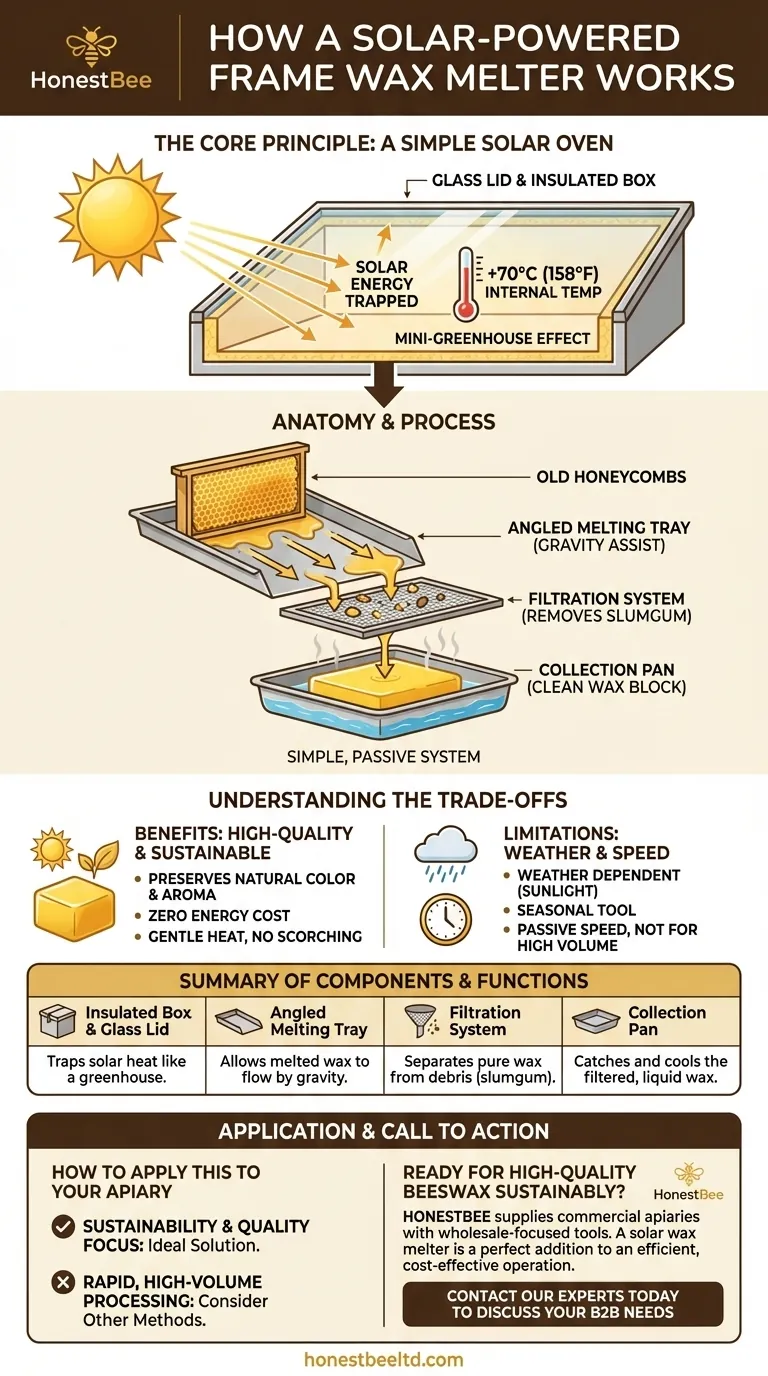

At its core, a solar-powered frame wax melter is a simple, insulated box with a glass lid that uses the sun's energy to melt beeswax from old honeycombs. It functions like a mini-greenhouse, trapping heat to liquefy the wax, which then drains by gravity through a filter and into a collection pan, separating it from leftover debris.

A solar wax melter is not just a tool; it's a strategy. It leverages the free, gentle heat of the sun to produce exceptionally high-quality beeswax with minimal effort and zero energy cost, making it an ideal solution for beekeepers who value sustainability and quality over raw speed.

The Core Principle: A Simple Solar Oven

A solar wax melter operates on a basic and reliable scientific principle. Understanding this is key to using it effectively.

The Greenhouse Effect in a Box

The device's transparent lid, typically made of glass or a durable plastic, allows sunlight to pass through and strike the dark honeycombs and the interior of the box. This light energy is absorbed and converted into heat. The lid then traps this heat, preventing it from escaping and steadily raising the internal temperature.

Reaching the Melting Point

This trapped solar energy can heat the inside of the melter to approximately +70°C (158°F) on a sunny day. This is well above the melting point of beeswax (around 62-64°C), allowing the wax to liquefy efficiently without being scorched by excessive temperatures.

Anatomy of a Solar Wax Melter

While designs vary slightly, all solar melters share a few critical components that work in unison.

The Insulated Box and Lid

The main body is an insulated box designed to retain as much heat as possible. The lid creates the seal that traps the heat, maximizing the sun's efficiency.

The Angled Melting Tray

Inside, old frames or loose comb pieces are placed on a metal tray or rack. This tray is set at a steep angle, using gravity to ensure that as the wax melts, it immediately flows downwards and away from the original comb material.

The Filtration System

As the liquid wax runs down the tray, it typically passes through a mesh screen or filter. This simple but crucial step separates the pure beeswax from the "slumgum"—the collection of old cocoons, pollen, propolis, and other debris left behind after the wax is rendered.

The Collection Pan

At the bottom of the slope, a collection pan catches the clean, filtered wax. Often, this pan contains a small amount of water. The hot wax drips onto the water, where it spreads out and solidifies, forming a clean block that is easy to remove once cool.

Understanding the Trade-offs

A solar melter is an excellent tool, but its effectiveness is defined by its inherent strengths and weaknesses.

Primary Benefit: High-Quality Wax

The gentle, relatively low temperature of a solar melter is its greatest asset for wax quality. Unlike high-heat methods that can darken or burn the wax, solar rendering preserves the natural yellow color and pleasant aroma of the beeswax.

The Obvious Limitation: Weather Dependency

The device is entirely dependent on strong, direct sunlight. It will not work on cloudy days, in the shade, or during cooler seasons. Its performance is directly tied to the weather, making it a seasonal tool in many climates.

Efficiency and Positioning

To maximize output, the melter must be positioned to face the sun directly. Some models include a rotating support to allow you to track the sun's path across the sky throughout the day, significantly improving melting efficiency.

Capacity and Speed

A solar melter is a passive system. It is not designed for rapid, high-volume industrial processing. It is best suited for small-to-medium-scale beekeepers who can process frames over several sunny days.

How to Apply This to Your Apiary

Choosing to use a solar wax melter depends entirely on your specific goals as a beekeeper.

- If your primary focus is sustainability and low operational cost: This is an unparalleled solution, as it reclaims a valuable resource using only free solar energy.

- If your primary focus is wax quality for crafts or sale: Solar melting produces a superior, clean, and beautifully colored wax block with minimal risk of scorching.

- If your primary focus is processing large volumes quickly: You may find the weather dependency and passive speed too limiting and should consider an electric or steam-based melter instead.

Ultimately, the solar wax melter is a powerful and elegant tool for the patient beekeeper who seeks to create value sustainably.

Summary Table:

| Component | Function |

|---|---|

| Insulated Box & Glass Lid | Traps solar heat like a greenhouse. |

| Angled Melting Tray | Allows melted wax to flow by gravity. |

| Filtration System | Separates pure wax from debris (slumgum). |

| Collection Pan | Catches and cools the filtered, liquid wax. |

| Key Characteristic | Details |

|---|---|

| Operating Temperature | Up to 70°C (158°F) on a sunny day. |

| Primary Benefit | Produces high-quality, un-scorched wax. |

| Main Limitation | Requires direct sunlight; weather-dependent. |

Ready to produce high-quality beeswax sustainably?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the wholesale-focused tools they need to succeed. A solar wax melter is a perfect addition to an efficient, cost-effective operation.

Contact our experts today to discuss the best wax processing equipment for your business needs.

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

People Also Ask

- Can you heat honey to separate from wax? A Guide to Preserving Honey Quality

- How can beeswax value-addition processes be utilized to increase beekeeping revenue? Boost Your Apiary Profitability

- Why is soft water recommended for industrial beeswax processing? Avoid Emulsions and Ensure High-Quality Purification

- What role do dedicated wax melting units play in wax processing? Maximize Your Apiary's Resource Recovery

- What role does a sun melting pot play in the post-harvest processing of honey? Optimize Quality and Reduce Fermentation

- What role does industrial-grade hydrogen peroxide play in beeswax? Mastering Bleaching for Premium White Beeswax

- What specialized equipment is required for the industrial processing and recycling of beeswax? Optimize Wax Recovery

- How should liquid beeswax be poured and stored after melting? Expert Guide for Pure, Long-Lasting Beeswax Blocks