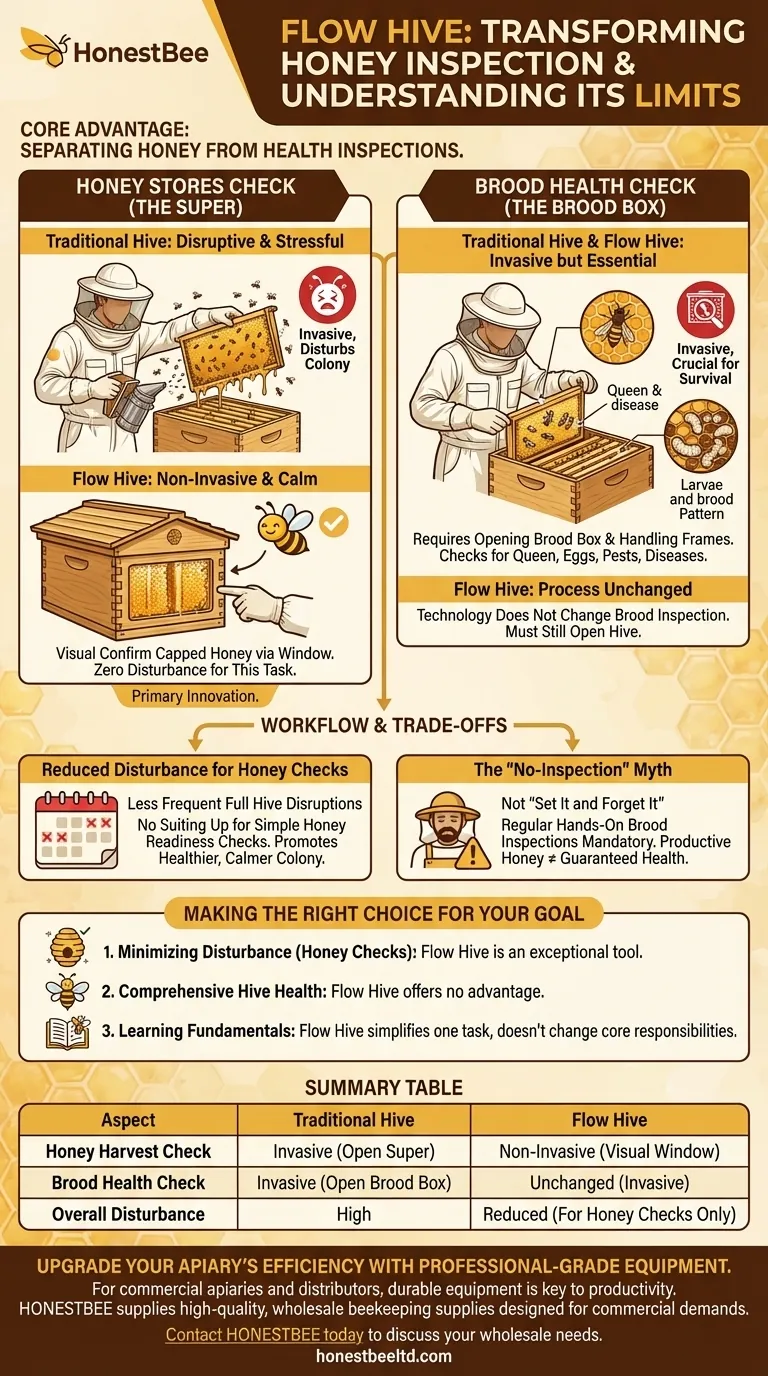

In essence, the Flow Hive improves one specific aspect of hive inspection: checking the honey stores. Its design allows a beekeeper to visually confirm if the honey is ready for harvest without opening the hive, which significantly reduces disturbance to the colony for that single task.

The core advantage of Flow Hive technology is its ability to separate the inspection for honey harvesting from the inspection for colony health. While it makes the former non-invasive, it does not alter or remove the need for traditional, hands-on inspections of the brood box to ensure the colony's survival.

The Two Core Components of a Hive Inspection

A complete hive inspection is not a single action but a series of checks on two distinct parts of the hive: the honey super and the brood box. Understanding this distinction is critical.

Checking Honey Stores (The Super)

Traditionally, checking if honey is ready for harvest requires opening the hive, using a smoker to calm the bees, and physically pulling out heavy frames. This process is disruptive and can stress the colony.

The Flow Hive's primary innovation is in the honey super. Its end-frame observation window allows you to see directly into the cells. This lets you determine if the bees have filled the frames and capped the honey, all from the outside.

Checking Brood Health (The Brood Box)

This is the most important inspection for the long-term health of your colony. It involves opening the brood box at the bottom of the hive to look for the queen, check her egg-laying pattern, and screen for pests like Varroa mites or diseases.

This part of the inspection is invasive by nature. The Flow Hive technology does not change this process. A beekeeper must still open the hive and physically handle the brood frames.

How Flow Hive Changes the Inspection Workflow

By creating a non-invasive way to check honey stores, the Flow Hive reduces the frequency of full hive disturbances, but not the necessity of them.

Reducing Disturbance for Honey Checks

With a Flow Hive, you no longer need to suit up and disassemble the honey super just to see if it's time to harvest. This is a significant reduction in stress for the bees and a major convenience for the beekeeper.

A calm colony is often a more productive and resilient one. Minimizing these disturbances contributes to a healthier overall hive environment.

The Observation Windows

The Flow Hive includes observation windows on the side of the honey super and the brood box. These windows provide a quick, external glimpse of bee activity and population density.

While useful for a quick check, these windows are not a substitute for a true internal inspection. They can tell you that the bees are active, but not how they are doing.

Understanding the Trade-offs and Limitations

The convenience of the Flow Hive can create a critical misunderstanding for new beekeepers. Its advantages for honey inspection do not extend to overall hive management.

The Myth of a "No-Inspection" Hive

The Flow Hive is not a "set it and forget it" system. Responsible beekeeping absolutely requires regular, hands-on brood box inspections, regardless of the hive type.

Neglecting these internal inspections because the honey super looks full from the outside is one of the most common and dangerous mistakes a new beekeeper can make.

Honey Production is Not a Guarantee of Health

A colony can appear incredibly productive, filling the Flow Frames with honey, while simultaneously suffering from a devastating pest infestation or disease in the brood box below.

Relying solely on the external windows can mask underlying problems until it is too late to save the colony.

Making the Right Choice for Your Goal

Understanding how Flow technology fits into your beekeeping practice is key to using it effectively.

- If your primary focus is minimizing disturbance during honey checks: The Flow Hive is an exceptional tool that makes assessing honey readiness a simple, external, and stress-free process.

- If your primary focus is comprehensive hive health and disease management: The Flow Hive offers no advantage here; you must still perform regular, invasive brood box inspections just as you would with a standard hive.

- If your primary focus is learning the fundamentals of beekeeping: Recognize that the Flow Hive simplifies one task but does not change the core responsibilities of monitoring and caring for the health of the colony.

By understanding its specific advantages and limitations, you can use the Flow Hive as a powerful tool without neglecting the fundamental duties of responsible beekeeping.

Summary Table:

| Inspection Aspect | Traditional Hive | Flow Hive |

|---|---|---|

| Honey Harvest Check | Invasive; requires opening super | Non-invasive; visual check via window |

| Brood Health Check | Invasive; requires opening brood box | Unchanged; still requires invasive inspection |

| Overall Disturbance | High for honey checks | Reduced for honey checks only |

Upgrade Your Apiary's Efficiency with Professional-Grade Equipment

For commercial apiaries and beekeeping equipment distributors, efficient hive management is key to productivity and profitability. While the Flow Hive offers a unique advantage for honey inspection, a successful operation relies on durable, reliable equipment for all aspects of beekeeping.

HONESTBEE supplies the professional tools you need. We provide high-quality, wholesale-focused beekeeping supplies and equipment—from standard hive components to protective gear and extraction tools—designed to withstand the demands of commercial use.

Let us help you build a more resilient and productive operation.

Contact HONESTBEE today to discuss your wholesale needs and discover how our equipment can support the health of your colonies and the growth of your business.

Visual Guide

Related Products

- Automatic Honey Flow Beehive 4 Frame Mini Hive for Beekeeping

- 7 x Auto Bee Flow Hive Frames Plastic Beekeeping Hive Box Supplies

- Professional Drop-Style Hive Handles for Beekeeping

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- Wholesales Dadant Size Wooden Bee Hives for Beekeeping

People Also Ask

- How does the Flow Hive work? A Look at the Revolutionary 'Honey on Tap' System

- What are the benefits of the Flow Hive for novice beekeepers? Simplify Honey Harvesting & Reduce Stress

- How does mechanical comb technology revolutionize honey collection? Low-Stress Direct Extraction Explained

- What potential issue can occur regarding bees' acceptance of plastic flow frames? Avoid Hive Swarming and Backfilling

- What is the overall assessment of Flow Hives? A Clear Look at the Pros and Cons

- Why might a standard configuration of a hive with flow frames lack sufficient space for the brood during summer? Avoid Swarming

- How do bees use Flow Frames? A Guide to Stress-Free Honey Harvesting

- What is the design principle of a beehive with built-in honey extraction? Modernizing the Langstroth Standard