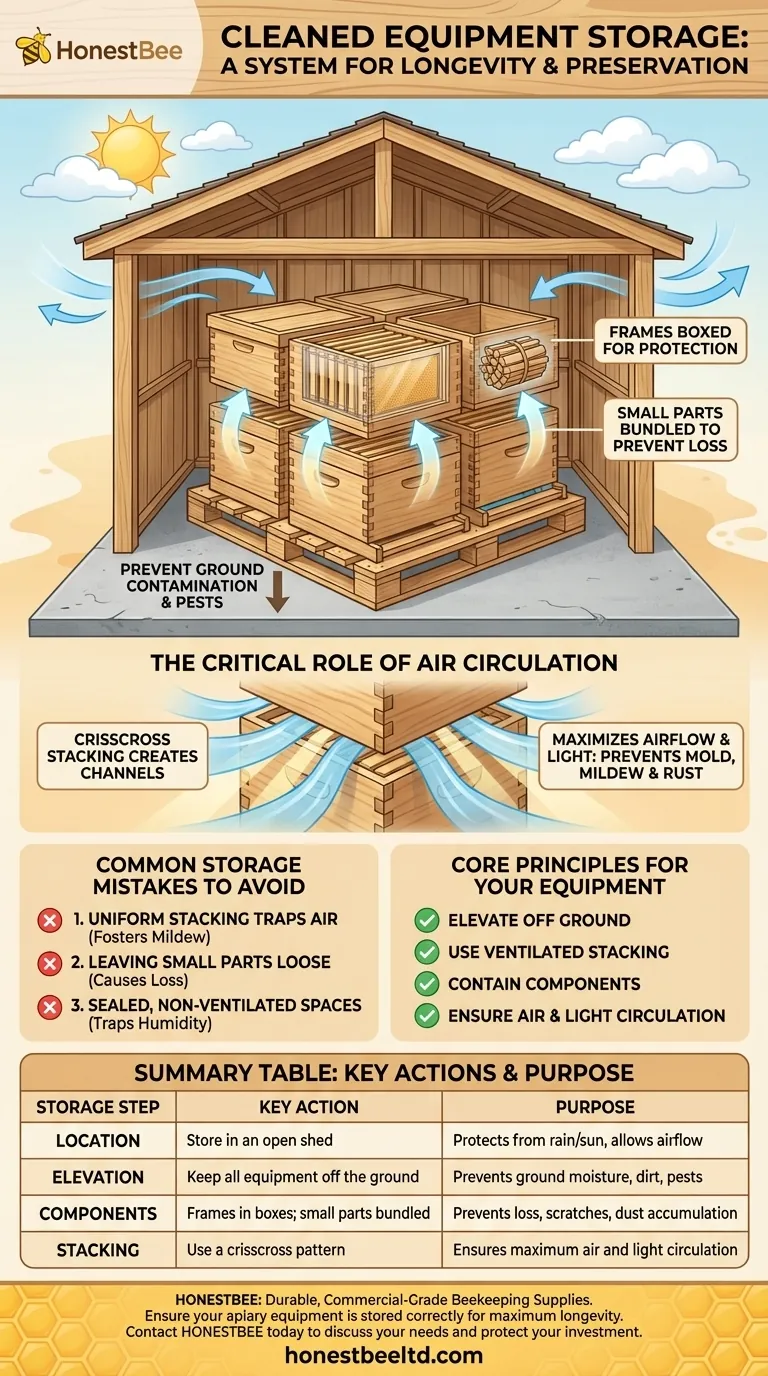

To ensure it remains in optimal condition, cleaned equipment is stored off the ground within an open shed. The frames are placed back into their boxes, while smaller removable wedge pieces are bundled together. These boxes are then stacked in a crisscross pattern to allow for proper ventilation.

The entire storage process is a deliberate system designed not just for organization, but to actively prevent moisture buildup and physical damage by ensuring constant air and light circulation.

The Core Principles of This Storage Method

The specific steps taken are designed to address the most common causes of equipment degradation: moisture, contamination, and physical damage. Each step serves a distinct protective purpose.

Protection from the Elements

The equipment is kept in an open shed. This provides a crucial balance, shielding the items from direct rain and harsh sun while still allowing for ample natural airflow.

Preventing Ground Contamination

Storing all items off the ground is a critical step. This prevents moisture from wicking up from the ground and protects the equipment from dirt, debris, and pests.

Maintaining Component Integrity

Placing the frames back in their boxes protects them from scratches, dust, and impacts. Bundling the smaller wedge pieces with a rubber band ensures these essential parts are not misplaced.

The Critical Role of Air Circulation

The most unique aspect of this procedure is the stacking method. It is the key to preventing the hidden threat of trapped moisture, which can cause damage even when equipment is under cover.

The Crisscross Stacking Method

Boxes are stacked in a crisscross pattern, with each box placed at a 90-degree angle to the one below it. This creates stable, open channels throughout the stack.

Why Airflow and Light Matter

This deliberate spacing allows air and light to circulate freely around every box. Constant airflow ensures any residual moisture evaporates completely, preventing the growth of mold, mildew, or the development of rust.

Common Storage Mistakes to Avoid

Failing to follow this method can inadvertently lead to equipment damage. The most common errors often involve trapping moisture or leaving components exposed.

Stacking Directly on a Solid Surface

Placing boxes directly on top of one another in a uniform stack traps air. This stagnant environment prevents drying and can foster mildew growth between the boxes.

Forgetting Small Components

Leaving small parts like the wedges loose is a primary cause of loss. Bundling them ensures they remain with the correct equipment set.

Storing in a Sealed, Non-Ventilated Space

While it may seem protective, storing equipment in a completely sealed room or container without airflow can be counterproductive. It can trap ambient humidity, creating a worse environment than an open-air shed.

How to Apply This to Your Equipment

The principles behind this method can be adapted for storing any type of cleaned equipment that is sensitive to moisture or damage.

- If your primary focus is preventing moisture damage: Always elevate your equipment off the ground and use a stacking method that creates channels for air to flow freely.

- If your primary focus is preventing loss and physical damage: Utilize original boxes or dedicated containers for main components and always bundle or bag smaller, loose parts.

- If your goal is long-term preservation: Combine all principles by storing equipment off the ground in a covered, well-ventilated area with a stacking pattern that maximizes air and light exposure.

Proper storage is the final step in the maintenance process, guaranteeing your equipment is ready and reliable for its next use.

Summary Table:

| Storage Step | Key Action | Purpose |

|---|---|---|

| Location | Store in an open shed | Protects from rain/sun while allowing airflow |

| Elevation | Keep all equipment off the ground | Prevents ground moisture, dirt, and pests |

| Components | Frames in boxes; small parts bundled | Prevents loss, scratches, and dust accumulation |

| Stacking | Use a crisscross pattern | Ensures maximum air and light circulation |

Ensure your apiary equipment is stored correctly for maximum longevity.

Moisture damage and lost parts can be costly. HONESTBEE supplies durable, commercial-grade beekeeping supplies and equipment designed to withstand rigorous use and proper storage. Our wholesale-focused operations provide distributors and commercial apiaries with the reliable tools needed for success.

Contact HONESTBEE today to discuss your equipment needs and protect your investment.

Visual Guide

Related Products

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Wholesales Dadant Size Wooden Bee Hives for Beekeeping

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- Yellow Plastic Bucket Pail Perch for Beekeeping

- Rigid Pith Style Beekeeper Hat for Square Folding Veils

People Also Ask

- How should beekeepers handle bees when using a hive tool? Master Calm, Deliberate Techniques

- What is the significance of professional hive-making tools? Scale Your Stingless Bee Farm with Precision Equipment

- What are the specific applications of a beekeeping chisel? Master Hive Maintenance with Precision Tools

- Why is it important to compare the progress of different hives? A Beekeeper's Key Diagnostic Tool

- What is the function of a professional stainless steel hive tool in IFB? Optimize Your Colony Strength Assessment