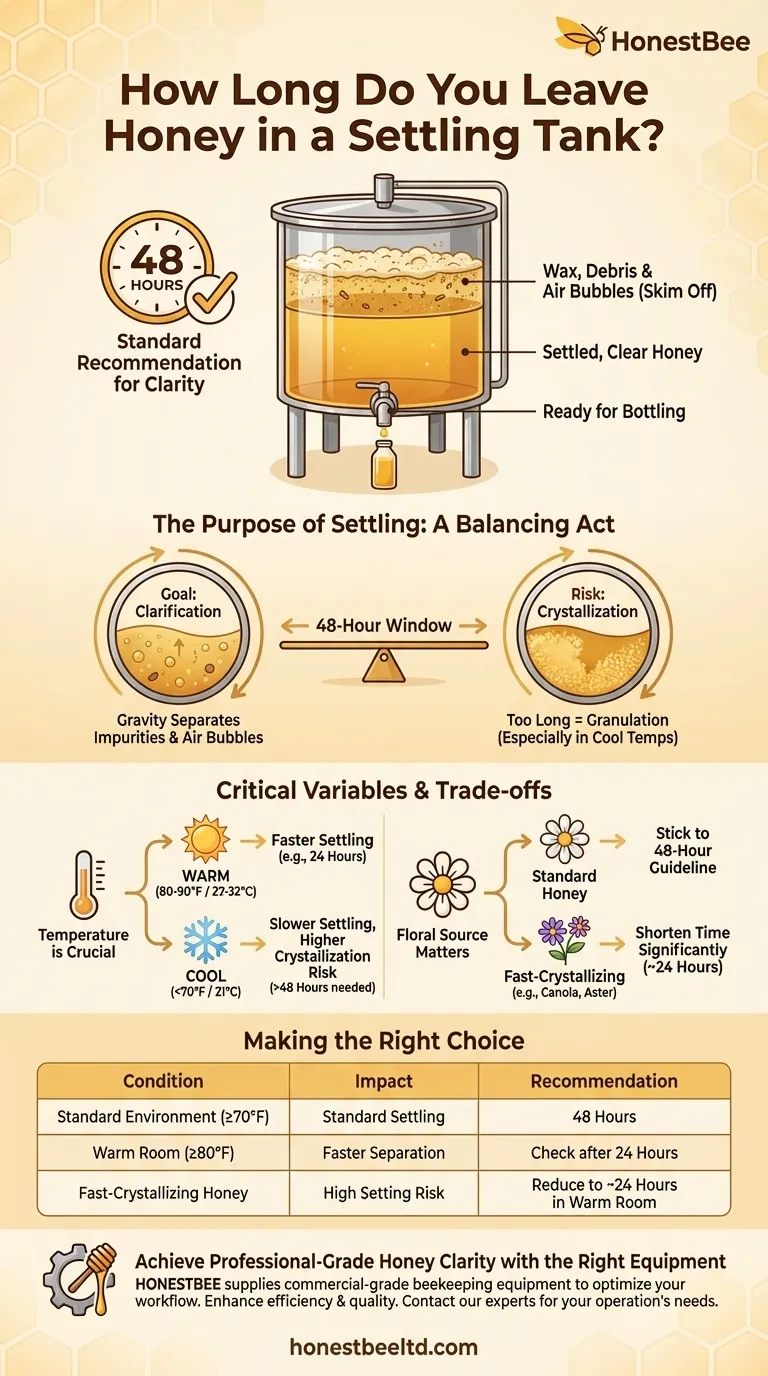

The standard recommendation is to leave honey in a settling tank for approximately 48 hours. This duration provides enough time for the vast majority of tiny air bubbles and fine particles, such as wax, to rise to the surface. The result is a clearer, more visually appealing final product ready for bottling.

The goal of settling is a balancing act. You need enough time for impurities and air to naturally separate, but not so much time that the honey begins its inevitable process of crystallization within the tank.

The Purpose of a Settling Tank

A settling tank is a simple but critical tool for post-extraction honey processing. It relies on gravity to clarify the honey without the need for aggressive filtering, which can remove beneficial pollen.

Removing Air Bubbles

The process of extraction, particularly with mechanical extractors and pumps, whips a significant amount of air into the honey. These microscopic bubbles create a cloudy or foamy appearance. A settling tank allows these bubbles to slowly rise and dissipate.

Separating Fine Debris

Small specks of beeswax or other fine hive debris that pass through initial strainers are typically less dense than honey. Over time, these particles will float to the top, forming a layer that can be skimmed off before bottling.

How Gravity and Viscosity Work

Honey is highly viscous, meaning it resists flow. This thickness slows down the separation process. The warmer the honey, the lower its viscosity, and the faster air and debris will rise. The settling tank simply provides an undisturbed environment for this slow, natural process to occur.

The Critical 48-Hour Window

The 48-hour guideline is based on achieving a clear result without introducing new problems.

What Happens Before 48 Hours

If you bottle the honey too soon, the settling process will not be complete. The honey will still contain suspended micro-bubbles. While not harmful, these will give the honey in the jar a hazy appearance and may form a foamy layer at the top over time.

The Risk of Waiting Too Long

Leaving honey in the tank for much longer than 48 hours, especially in cooler temperatures, encourages crystallization. Honey is a supersaturated sugar solution, and it naturally wants to "set" or crystallize. Allowing it to sit completely still for an extended period can trigger this process, making it difficult to bottle.

Understanding the Trade-offs and Key Variables

While 48 hours is a reliable rule of thumb, the optimal time is influenced by several factors. Blindly following the rule without considering your conditions can lead to suboptimal results.

Honey Temperature is Crucial

Temperature is the single most important variable. Honey kept in a warm room (80-90°F / 27-32°C) will be far less viscous. In these conditions, settling may be complete in as little as 24 hours. Conversely, honey in a cool basement will settle much slower and be more prone to crystallization.

Honey's Floral Source Matters

Different floral sources produce honey with different characteristics. Some types, like canola, aster, or ivy honey, are known to crystallize extremely quickly. For these varieties, you may need to shorten the settling time significantly and work in a very warm environment.

The Importance of Skimming

The process isn't just about waiting. After the settling period, the layer of foam and wax debris on the surface must be carefully skimmed off. Failing to do this step negates the entire purpose of the settling tank.

Making the Right Choice for Your Goal

Adjust your settling time based on your specific environment and honey type.

- If your primary focus is maximum clarity in a standard environment: Stick to the 48-hour guideline in a room that is at least 70°F / 21°C.

- If you are working in a dedicated warm room (80°F+ / 27°C+): Check your honey after 24 hours, as it will likely be fully settled and ready for bottling.

- If your honey is known to crystallize very quickly: Settle for a shorter period (e.g., 24 hours) in the warmest environment possible to bottle it before it begins to set.

Properly settling your honey is a simple, patient step that dramatically elevates the quality and appearance of your final product.

Summary Table:

| Factor | Impact on Settling Time | Recommendation |

|---|---|---|

| Standard Environment | Standard settling duration | 48 hours is the general guideline. |

| Warm Temperature (>80°F / 27°C) | Faster separation of bubbles/debris | Check after 24 hours; may be ready. |

| Fast-Crystallizing Honey (e.g., Canola) | High risk of setting in the tank | Reduce time to ~24 hours in a warm room. |

| Cool Temperature (<70°F / 21°C) | Slower separation, risk of crystallization | Ensure room is warm; may need >48 hours. |

Achieve Professional-Grade Honey Clarity with the Right Equipment

For commercial apiaries and beekeeping equipment distributors, consistent, high-quality honey is essential for your brand and customers. The 48-hour settling rule is a key step, but it relies on having durable, efficient processing equipment.

HONESTBEE supplies the commercial-grade beekeeping supplies and equipment you need to optimize your entire honey production workflow, from extraction to bottling. We help you enhance efficiency, ensure product quality, and maximize your yield.

Ready to improve your honey processing results? Contact our wholesale experts today to discuss your operation's specific needs.

Visual Guide

Related Products

- Stainless Steel Honey Storage and Settling Tank with Double Strainer

- Professional Honey Storage Tank with Agitation System

- Stainless Steel Heated Honey Tank Warming Heating Tank

- Professional Honey Filter with Tripod Support Stand

- Stainless Steel Uncapping Tank with Stand and Strainer

People Also Ask

- What is the function of stainless steel settling tanks in honey processing? Achieve Natural Purity and Clarity

- What are the advantages of using modern honey storage equipment? Preserve the Value of Forest By-Products Efficiently

- How do food-grade honey storage tanks and filling equipment contribute to the commercialization of bee products?

- What is the role of specialized settling containers with side nozzles? Optimize Your Honey Primary Filtration

- What are the functions of settling tanks and bulk storage tanks in beekeeping? Achieve Commercial-Grade Honey Clarity