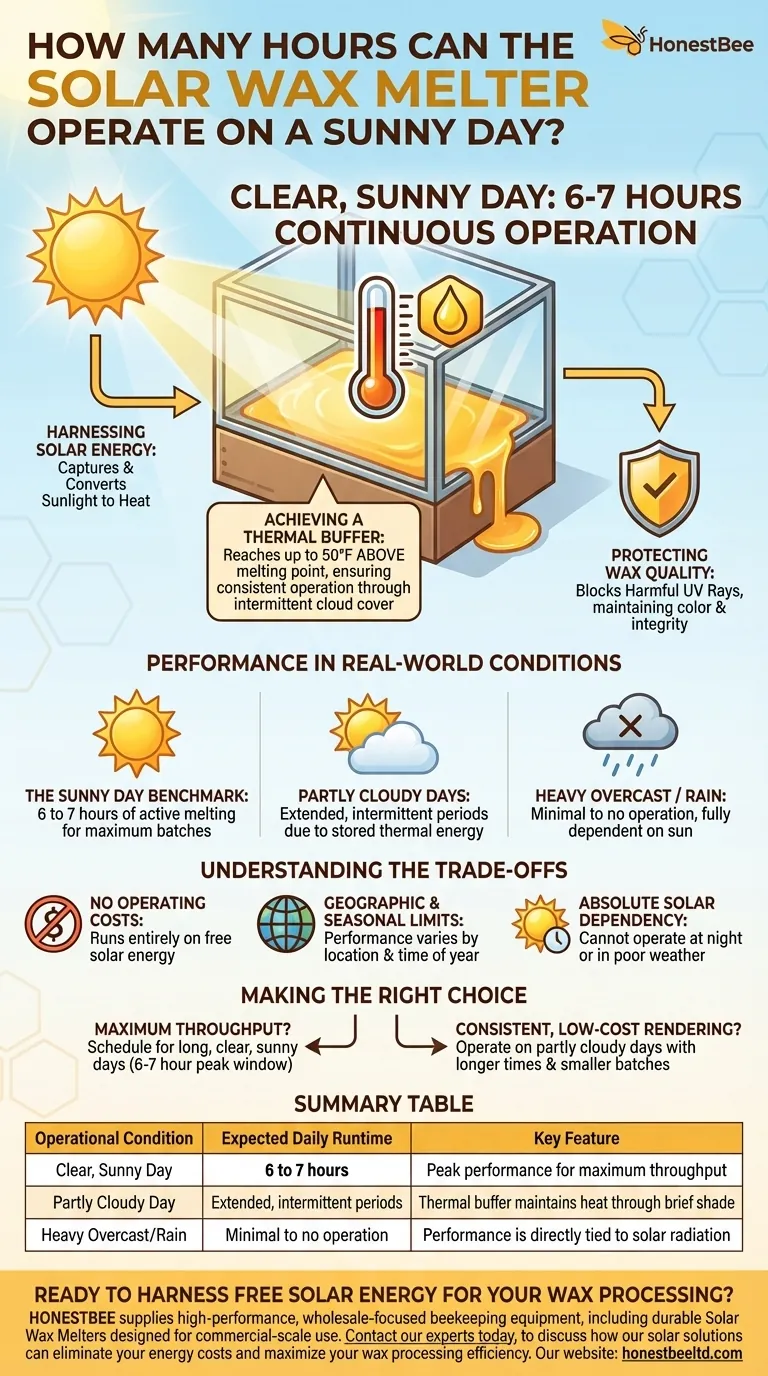

On a clear, sunny day, a Solar Wax Melter is designed to operate effectively for a continuous period of 6 to 7 hours. This operational window allows for the complete processing of wax from combs or cappings without any external power source.

The key to the Solar Wax Melter's performance is not just its ability to reach melting temperature, but its capacity to maintain a significant thermal buffer above the melting point, ensuring consistent operation even through intermittent cloud cover.

How the Melter Sustains Performance

A solar melter's design is straightforward but highly effective. It translates sunlight into thermal energy to liquefy wax for rendering and cleaning.

Harnessing Solar Energy

The device functions as a passive solar collector. It captures sunlight and converts it into heat, which becomes trapped inside the unit, steadily raising the internal temperature.

Achieving a Thermal Buffer

Crucially, the melter is engineered to achieve temperatures up to 50 degrees Fahrenheit above the melting point of wax. This surplus heat creates a thermal buffer, meaning the wax stays liquid even if the sun is temporarily obscured by a cloud.

Protecting Wax Quality

High-quality melters are also designed to protect the wax from direct, harmful UV rays. This ensures the final rendered wax maintains its quality and color without being photodegraded.

Performance in Real-World Conditions

While the benchmark for performance is a perfectly sunny day, the melter's utility is not limited to ideal conditions. Its effectiveness is determined by the availability of solar radiation.

The Sunny Day Benchmark

Under direct, uninterrupted sun, you can reliably expect 6 to 7 hours of active melting. This is the peak operational window for processing the largest batches of wax.

Operation on Partly Cloudy Days

The melter can still provide extended periods of melting on partly cloudy days. The stored thermal energy allows it to ride through brief periods of shade, though the overall time to melt a full batch may be longer.

Understanding the Trade-offs

The Solar Wax Melter is an efficient tool, but its effectiveness is governed by natural factors. Understanding these limitations is key to using it successfully.

Absolute Solar Dependency

The primary trade-off is its complete reliance on the sun. It cannot operate at night, on heavily overcast days, or during rain. Its performance is directly tied to the weather.

No Operating Costs

The significant advantage is the total elimination of operating costs. Once acquired, the device runs entirely on free solar energy, unlike electric alternatives.

Geographic and Seasonal Limits

Performance will naturally vary based on your geographic location and the time of year. Longer summer days with a high sun angle provide the best results, while shorter, overcast winter days will significantly reduce the operational window.

Making the Right Choice for Your Goal

To use a Solar Wax Melter effectively, align your workflow with its operational characteristics.

- If your primary focus is maximum throughput: Schedule your wax processing for long, clear, sunny days to take full advantage of the 6-to-7-hour peak performance window.

- If your primary focus is consistent, low-cost rendering: You can operate effectively on partly cloudy days, but you should anticipate longer processing times and plan for smaller batches.

By aligning your work with the weather, the Solar Wax Melter becomes a highly efficient and cost-free tool for processing your wax.

Summary Table:

| Operational Condition | Expected Daily Runtime | Key Feature |

|---|---|---|

| Clear, Sunny Day | 6 to 7 hours | Peak performance for maximum throughput |

| Partly Cloudy Day | Extended, intermittent periods | Thermal buffer maintains heat through brief shade |

| Heavy Overcast/Rain | Minimal to no operation | Performance is directly tied to solar radiation |

Ready to harness free solar energy for your wax processing?

For commercial apiaries and beekeeping equipment distributors, efficient wax rendering is key to profitability. HONESTBEE supplies high-performance, wholesale-focused beekeeping equipment, including durable Solar Wax Melters designed for commercial-scale use.

Contact our experts today to discuss how our solar solutions can eliminate your energy costs and maximize your wax processing efficiency.

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Stainless Steel Honey Press Wax Press with Tank

People Also Ask

- What are the safety precautions when working with melted beeswax? Prevent Burns and Fire Hazards

- What are wax melters used for? Unlock Efficient Wax Processing for Your Business

- What factors should be considered when choosing a wax melter? Optimize Your Beekeeping Efficiency

- What is the flash point of beeswax, and why is it important? Essential Safety Guide for Beekeepers

- How can you monitor the temperature of beeswax as it melts? Ensure Quality & Safety with Precise Control