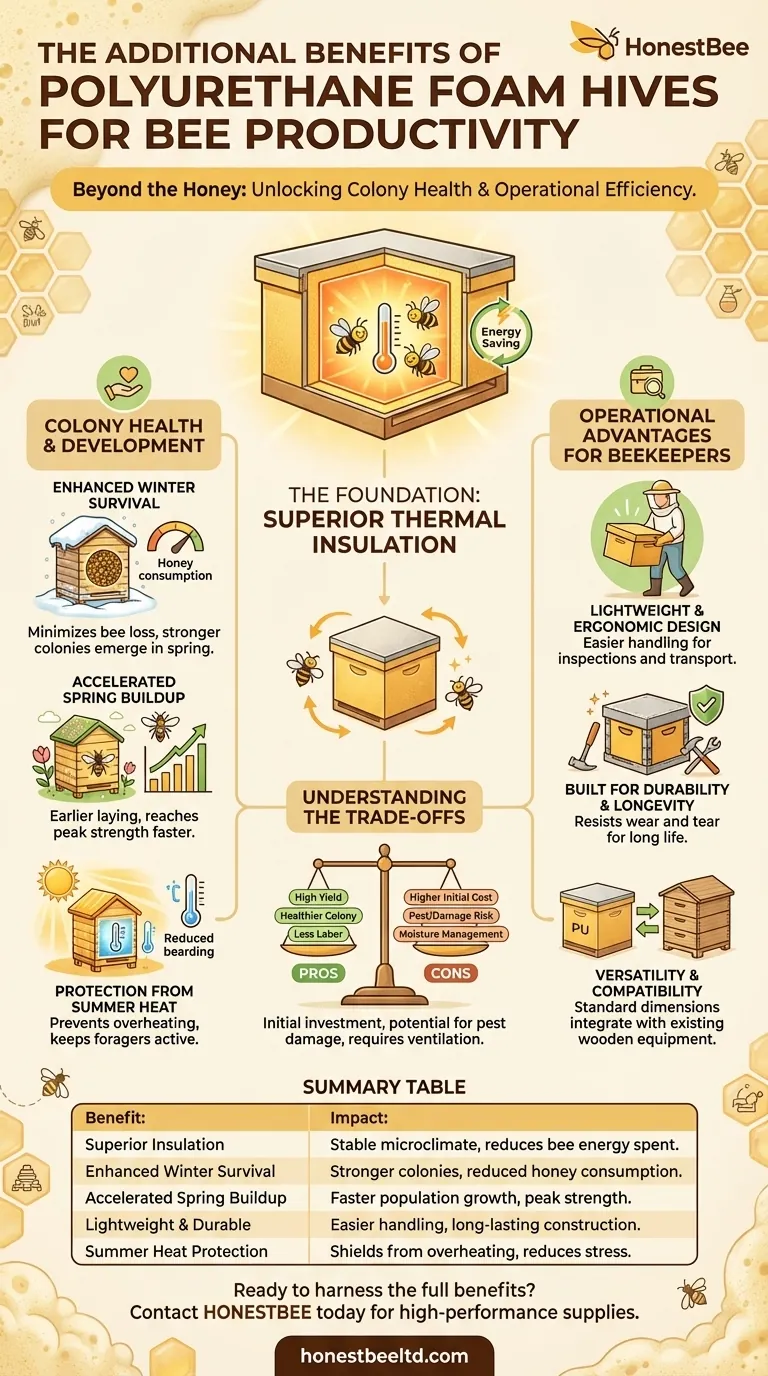

Beyond the honey, polyurethane foam hives offer a cascade of benefits that impact the entire lifecycle and management of a bee colony. While the 30% increase in honey production is a significant headline, it is the result of underlying improvements in colony health, seasonal resilience, and operational efficiency for the beekeeper.

The core advantage of polyurethane hives is their superior thermal insulation. This single property creates a stable internal microclimate, which not only frees up the bees' energy for production but also leads to stronger colonies, higher winter survival rates, and a more manageable experience for the beekeeper.

The Foundation: Unmatched Thermal Insulation

The primary driver behind every benefit of a polyurethane (PU) hive is its ability to insulate. This creates a stable environment that shields the colony from external temperature swings.

A Stable Microclimate

Polyurethane foam is a profoundly effective insulator, often cited as being ten times "warmer" than wood. This means it drastically reduces the energy transfer between the inside of the hive and the outside world.

Reduced Energy Expenditure

In any hive, bees must work constantly to maintain the brood nest at a stable temperature (around 95°F or 35°C). Because PU foam does most of this work for them, the bees expend far less energy on heating and cooling, freeing up that energy for other critical tasks.

How Insulation Creates a More Productive Colony

This saved energy is reinvested directly into activities that strengthen the colony, leading to tangible benefits throughout the year.

Enhanced Winter Survival

In a traditional wooden hive, a winter cluster must burn through significant honey stores simply to generate enough heat to survive. The insulation of a PU hive dramatically lessens this burden, leading to minimal bee loss during the cold months and a stronger, healthier colony emerging in the spring.

Accelerated Spring Development

Protected from late frosts and cold snaps, colonies in PU hives begin their spring buildup earlier. The stable warmth encourages the queen to start laying sooner, allowing the colony to grow its population and reach peak strength faster than those in wooden hives.

Protection from Summer Heat

Insulation works both ways. During peak summer heat, a PU hive shields the colony from overheating. This reduces stress and prevents the "bearding" behavior where large numbers of bees must exit the hive to cool it, taking them away from foraging duties.

Operational Advantages for the Beekeeper

The benefits extend beyond the bees themselves, making the physical work of beekeeping easier and more efficient.

Lightweight and Ergonomic Design

Polyurethane hives are significantly lighter than their wooden counterparts. This makes lifting boxes, performing inspections, and transporting hives for migratory beekeeping a far less strenuous task, benefiting both hobbyists and large-scale professionals.

Built for Durability and Longevity

Modern PU hives are often manufactured in monolithic forms, ensuring a solid and reliable construction. Many feature reinforced corners and edges, allowing the beekeeper to use hive tools and scrapers without causing the damage that can occur on softer materials.

Versatility and Compatibility

These hives are designed to perform well in any context, from a stationary backyard apiary to a large, nomadic operation. Furthermore, many are manufactured to be compatible with standard Langstroth dimensions, allowing beekeepers to integrate PU components with their existing wooden equipment.

Understanding the Trade-offs

No single material is perfect for every situation. A trusted advisor must acknowledge the potential downsides to provide a complete picture.

Initial Cost

Polyurethane hives typically have a higher upfront purchase price compared to traditional pine or cedar hives. This initial investment must be weighed against the long-term gains in productivity and colony survival.

Susceptibility to Pests and Physical Damage

While durable, PU foam can be damaged by pests like mice or wax moths if an entrance is left unprotected. It can also be dented or punctured by sharp impacts more easily than solid wood.

Moisture Management

Because PU is non-porous and highly insulating, condensation can sometimes form inside the hive if ventilation is not managed properly. Beekeepers using these hives must ensure adequate airflow to prevent a damp environment.

Making the Right Choice for Your Apiary

Your decision should be guided by your specific goals as a beekeeper.

- If your primary focus is maximizing honey yield and rapid colony growth: Polyurethane is the superior choice due to its unmatched thermal efficiency.

- If your primary focus is operational efficiency and physical ease of use: The lightweight nature of PU hives offers a significant advantage, especially for large-scale or migratory beekeeping.

- If your primary focus is the lowest initial cost or traditional aesthetics: Traditional wooden hives remain a viable option, but you must be prepared to manage their thermal disadvantages.

Ultimately, choosing your hive material is about selecting the right tool to achieve your beekeeping objectives.

Summary Table:

| Benefit | Key Impact for Bees & Beekeepers |

|---|---|

| Superior Insulation | Creates a stable microclimate, reducing bee energy spent on temperature regulation. |

| Enhanced Winter Survival | Stronger colonies emerge in spring due to reduced heat loss and honey consumption. |

| Accelerated Spring Buildup | Queen starts laying earlier, leading to faster population growth and peak strength. |

| Lightweight & Durable | Easier handling for beekeepers and long-lasting, robust construction. |

| Summer Heat Protection | Shields bees from overheating, reducing stress and keeping foragers on task. |

Ready to harness the full benefits of polyurethane foam hives in your operation?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with high-performance, wholesale-focused beekeeping supplies. Our polyurethane hives are designed to deliver the thermal efficiency and durability your business needs to maximize honey production and ensure colony health year-round.

Contact HONESTBEE today to discuss your needs and discover how our equipment can boost your productivity and profitability.

Visual Guide

Related Products

- Professional Insulated Winter Hive Wrap for Beekeeping

- Professional Insulated Plastic Bee Hives

- Honey Flow Garden Bee Hive Flow Hive Best Beehive for Beginners

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

People Also Ask

- What is the critical function of top insulation covers in a winterized beehive? Maximize Colony Survival with Heat Trapping

- Is it always necessary to insulate beehives? A Guide to Winter Survival & Colony Health

- How does insulation help bee hives in severely cold weather? Conserve Energy & Ensure Colony Survival

- What key factors should a beekeeper consider before wrapping a beehive? 3 Essentials for Winter Survival

- How do insulation wraps and hive wraps protect bee colonies during winter? Maximize Survival & Honey Reserves