The key customization options for honey filling machines center on the filling mechanism, container handling capabilities, and integrated automation features. These adaptations ensure the equipment can handle your specific honey viscosity, packaging format—from jars to sticks—and desired production speed, ensuring accuracy and efficiency.

Choosing the right honey filling machine is not about finding the "best" technology, but about correctly matching the machine's capabilities to the unique properties of your honey and your specific operational goals, such as speed, accuracy, and scale.

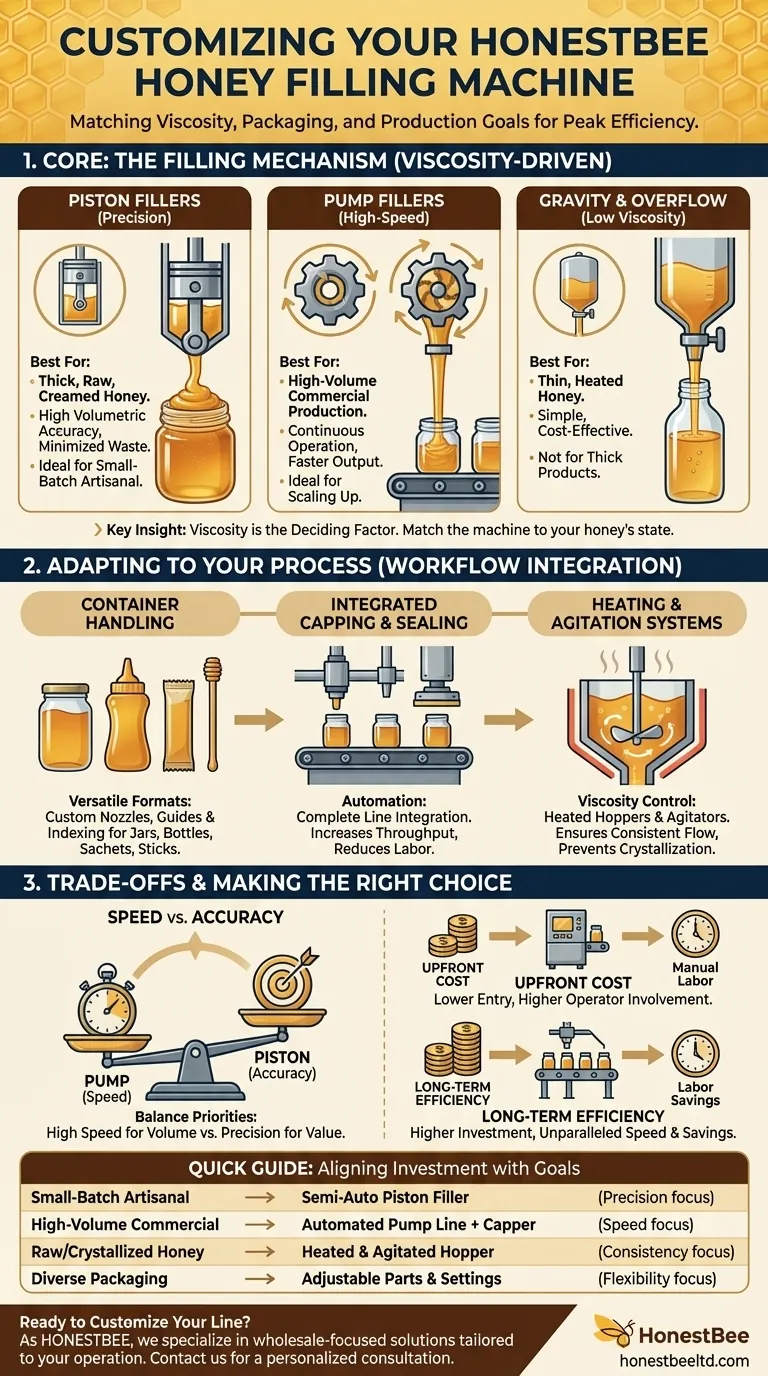

Core Customization: The Filling Mechanism

The heart of any honey filler is its dispensing mechanism. The viscosity of your honey—how thick or thin it is—is the single most important factor in determining the right technology for your operation.

Piston Fillers: The Standard for Precision

Piston fillers are the most common choice for honey due to their accuracy and ability to handle high viscosity. They use a cylinder and piston to draw in a precise volume of honey and then dispense it into the container.

This method provides exceptional volumetric accuracy, minimizing product waste and ensuring consistent fills every time. It is the ideal choice for thick, raw, or creamed honey.

Pump Fillers: Built for High-Speed Production

Pump-based systems, such as gear or lobe pumps, are designed for high-speed, high-volume commercial operations. The pump runs for a set amount of time to dispense the required volume of honey.

While potentially less precise than a piston filler on a per-fill basis, their continuous operation makes them significantly faster for large-scale production lines.

Gravity and Overflow Fillers: For Lower Viscosity

Gravity fillers rely on the weight of the honey in an overhead tank to fill containers. Overflow fillers fill the container to a specific level, with excess product returning to the tank.

These methods are best suited for honey with lower viscosity. They are often simpler and more cost-effective but are not ideal for thick, unheated honey as the flow rate would be too slow.

Adapting to Your Packaging and Process

Beyond the filling mechanism, a machine must be tailored to your entire production workflow, from the container you use to the final sealed product.

Container Handling Systems

Machines can be customized to handle virtually any packaging format. This includes specialized systems for jars, bottles, flexible sachets, or single-serve honey sticks.

This often involves custom-fit nozzles, container guides, and automated indexing systems or conveyor belts that move containers into position for filling.

Integrated Capping and Sealing

For a more automated solution, filling machines can be integrated with capping or sealing mechanisms. This creates a complete production line that fills a jar and immediately applies and tightens a lid.

This level of automation dramatically increases throughput and reduces the need for manual labor, making it a key consideration for scaling your business.

Heating and Agitation Systems

Honey's viscosity is highly sensitive to temperature. A crucial customization is the addition of a heated hopper or tank, often equipped with an agitator.

Heating gently lowers the honey's viscosity, allowing it to flow more easily and be filled more quickly and accurately. An agitator keeps the product temperature consistent and prevents crystallization in the hopper.

Understanding the Trade-offs

Choosing the right options involves balancing competing priorities. An objective assessment of these trade-offs is critical to making a sound investment.

Speed vs. Accuracy

There is a classic trade-off between filling speed and volumetric accuracy. Piston fillers offer the highest accuracy but may have a slower cycle rate than pump fillers, which are built for speed. Your choice depends on whether your priority is minimizing waste with a high-value product or maximizing units per hour.

Product Viscosity is the Deciding Factor

You cannot force a machine to work with the wrong product. A simple gravity filler will be ineffective and slow with thick, raw honey. Conversely, using a heavy-duty piston filler for a very thin, low-viscosity honey might be overkill. The machine must be matched to the honey's natural state or a state achieved through heating.

Upfront Cost vs. Long-Term Efficiency

A semi-automatic, single-nozzle piston filler has a relatively low entry cost but requires significant operator involvement. A fully automated, integrated line with heating, filling, and capping represents a major capital investment but delivers unparalleled speed and labor savings over time.

Making the Right Choice for Your Operation

Selecting the right machine configuration comes down to a clear understanding of your product and your business goals.

- If your primary focus is small-batch artisanal honey: A semi-automatic piston filler provides the precision you need to minimize waste without the cost of a fully automated line.

- If your primary focus is high-volume commercial production: An automated line with a pump filler, conveyor, and integrated capper is essential for achieving the necessary speed and efficiency.

- If you work with raw or easily crystallized honey: Prioritize a machine with a heated and agitated hopper to ensure consistent product flow and accurate fills.

- If you plan to use diverse packaging types: Select a machine with easily swappable parts and adjustable fill settings to maintain flexibility as your product line evolves.

By understanding these core options, you can invest in a machine that is not just a piece of equipment, but a true asset tailored to your production needs.

Summary Table:

| Customization Area | Key Options | Best For |

|---|---|---|

| Filling Mechanism | Piston Filler, Pump Filler, Gravity Filler | Precision, High-Speed, or Low-Viscosity Honey |

| Container Handling | Jars, Bottles, Sachets, Honey Sticks | Specific Packaging Formats |

| Automation & Integration | Heated Hoppers, Agitators, Capping Systems | Raw/Crystallized Honey, High-Volume Production |

| Primary Trade-off | Speed vs. Accuracy, Upfront Cost vs. Long-Term Efficiency | Aligning Investment with Business Goals |

Ready to Customize Your Honey Filling Line?

As HONESTBEE, we specialize in supplying the right beekeeping supplies and equipment to commercial apiaries and distributors. We understand that the perfect honey filling machine is not one-size-fits-all. Let us help you select and customize equipment that precisely matches your honey's viscosity, packaging needs, and production goals—boosting your accuracy, efficiency, and profitability.

Contact HONESTBEE today for a personalized consultation and discover how our wholesale-focused solutions can power your operation.

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- How do automated filling and packaging machines contribute to the market value of honey products? Boost Retail Profits

- How does professional labeling and filling equipment add value to stingless bee products? Maximize Your Market Premium

- What are the features of a twin honey stick machine? Double Your Production & Versatility

- Why is honey packaging important? Protect Quality, Build Your Brand & Boost Sales

- Which method is used for liquid filling? Find the Perfect Solution for Your Product

- What are the advantages of using an automatic honey filling machine? Ensure Superior Quality and Moisture Control

- How does a volume honey filling machine ensure accurate filling? Precision Filling for Maximum Product Value

- What is the role of the emergency stop button in a honey stick machine? A Critical Safety Mechanism Explained