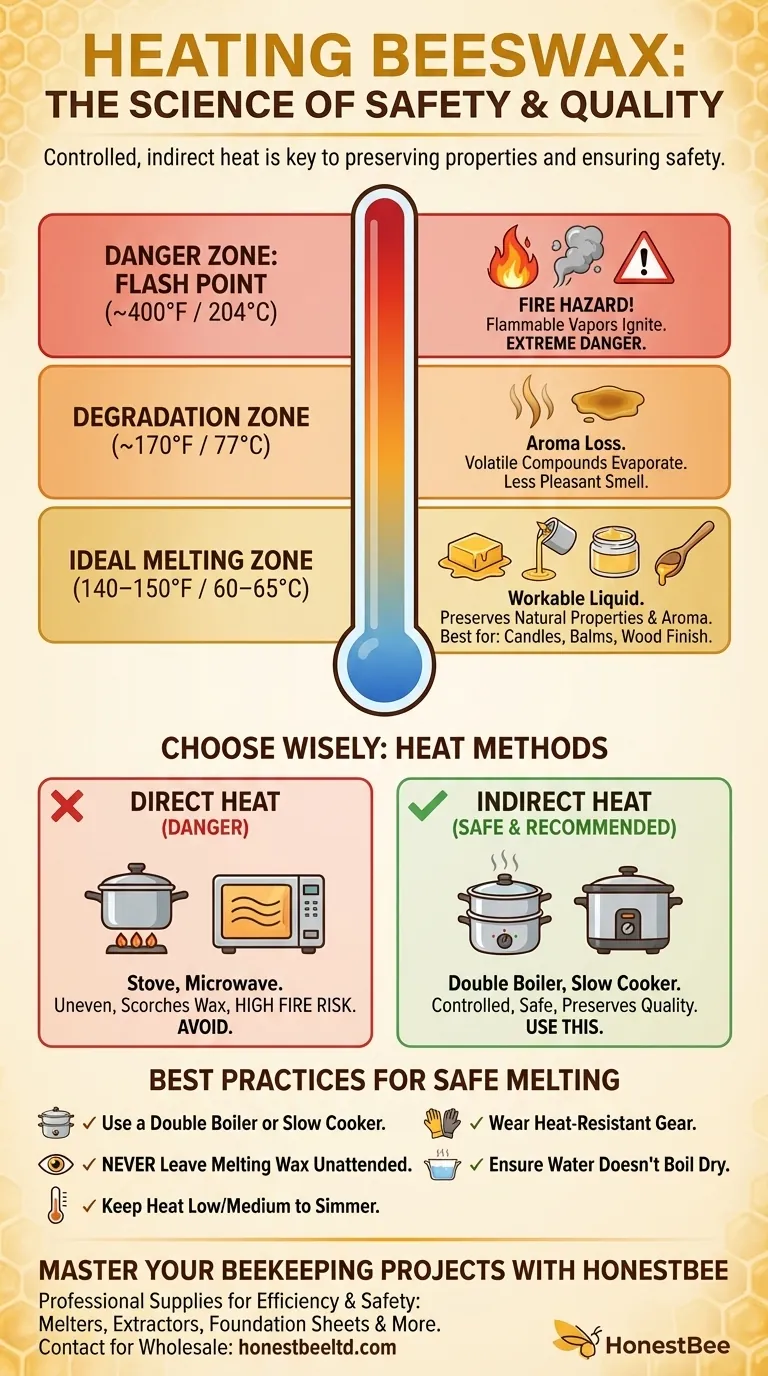

In short, heating beeswax causes it to melt into a liquid, but the temperature you use is critical. When heated correctly to its melting point of 140–150°F (60–65°C), it becomes a workable liquid ideal for projects. However, if overheated, it will lose its desirable aroma, and at significantly higher temperatures, it can become a serious fire hazard.

The core principle of working with beeswax is to use controlled, indirect heat. This method safely melts the wax without degrading its natural properties or creating a risk of fire, ensuring both quality and safety for your project.

The Stages of Heating Beeswax

Understanding how beeswax behaves at different temperatures is the key to handling it effectively. The process isn't just a simple transition from solid to liquid; it's a spectrum with distinct stages.

The Melting Point (140–150°F)

This is the ideal temperature range. Within these temperatures, the solid wax will gently transition into a clean, golden liquid.

At this stage, the wax is perfect for pouring into molds for candles, mixing into balms and salves, or applying as a wood finish. All its natural properties are fully intact.

The Point of Degradation (~170°F)

Once the temperature rises above approximately 170°F (77°C), the quality of the beeswax begins to degrade.

The most noticeable change is the loss of its subtle, honey-like aroma. The heat causes the delicate volatile compounds responsible for the scent to evaporate, leaving the wax with a less pleasant, slightly burnt smell.

The Flash Point (~400°F)

This is the critical danger zone. The flash point of beeswax is approximately 400°F (204°C).

At this temperature, the hot wax releases flammable vapors that can ignite if exposed to an open flame. This is why you must never leave melting wax unattended or heat it over a direct flame.

Understanding the Trade-offs: Direct vs. Indirect Heat

The method you choose to melt beeswax directly impacts both the quality of your final product and your personal safety. The choice between direct and indirect heat is not a matter of preference—it's a matter of control.

Why Direct Heat is Dangerous

Placing a pot of beeswax directly on a stove burner or in a microwave is extremely risky. These methods introduce intense, uneven heat that is very difficult to regulate.

This lack of control makes it easy to scorch the wax, ruining its properties. More importantly, it dramatically increases the risk of accidentally reaching the flash point and starting a fire.

The Safety of Indirect Heat

Indirect heat is the universally recommended method for melting beeswax safely. This involves using a double boiler or a slow cooker.

A double boiler works by using steam from simmering water to gently heat the container holding the wax. This design makes it physically impossible for the wax to get much hotter than the boiling point of water (212°F or 100°C), keeping it far below the dangerous flash point.

Best Practices for Safe Melting

Always adhere to these safety protocols:

- Use a dedicated double boiler or create one by placing a heat-safe bowl over a pot with a few inches of simmering water.

- Never leave melting wax unattended.

- Keep the heat on low or medium-low to maintain a gentle simmer.

- Ensure the water in the bottom pot does not boil away completely.

- Use heat-resistant tools and containers when handling the hot, liquid wax.

Making the Right Choice for Your Goal

Your approach should be dictated by your end goal. By controlling the temperature, you control the outcome.

- If your primary focus is preserving the natural aroma and color: Use a double boiler and a thermometer to keep the temperature just above the melting point (150-160°F) and no higher.

- If your primary focus is safety and simplicity: A double boiler or a slow cooker on its lowest setting is the best choice, as these methods self-regulate the heat and prevent overheating.

- If your primary focus is filtering raw, unfiltered beeswax: You may need slightly higher temperatures (around 180-190°F) to lower the wax's viscosity for easier filtering, but remain vigilant and stay far from the flash point.

By respecting its properties and using controlled heat, you can safely unlock the full potential of beeswax for any project.

Summary Table:

| Temperature | State & Key Effect | Best For |

|---|---|---|

| 140–150°F (60–65°C) | Melts into a workable liquid. | Pouring candles, making balms, wood finishing. |

| ~170°F (77°C) | Aroma degrades, scent is lost. | N/A (a stage to avoid). |

| ~400°F (204°C) | Flash point: Fire hazard. | N/A (extreme danger). |

Master Your Beekeeping Projects with the Right Supplies

Heating beeswax correctly is just one step in creating high-quality products. Whether you're a commercial apiary or a beekeeping equipment distributor, having reliable, professional-grade supplies is essential for efficiency and safety.

HONESTBEE provides the durable equipment and wholesale supplies you need to succeed, from high-quality foundation sheets to efficient melters and extractors.

Ready to elevate your beekeeping operations? Contact our team today to discuss your wholesale needs and discover how we can support your business growth.

Visual Guide

Related Products

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- 10L Stainless Steel Honey Wax Press Extractor for Wax Cappings

- Colorful Silicone Beeswax Foundation Mold Mould for Beekeeping

People Also Ask

- What is the primary function and advantage of a solar wax melter? Produce Premium, High-Purity Beeswax Naturally

- What is done with the beeswax cappings after they are removed? Turn Your Hive Byproducts into Gold

- What is the specific function of applying melted natural beeswax? Boost Your Hive Occupancy with Biological Lures

- How do industrial steam wax melters and mechanical wax pressers work together to improve wax recovery? Maximize Yield

- What role does a sun melting pot play in the post-harvest processing of honey? Optimize Quality and Reduce Fermentation