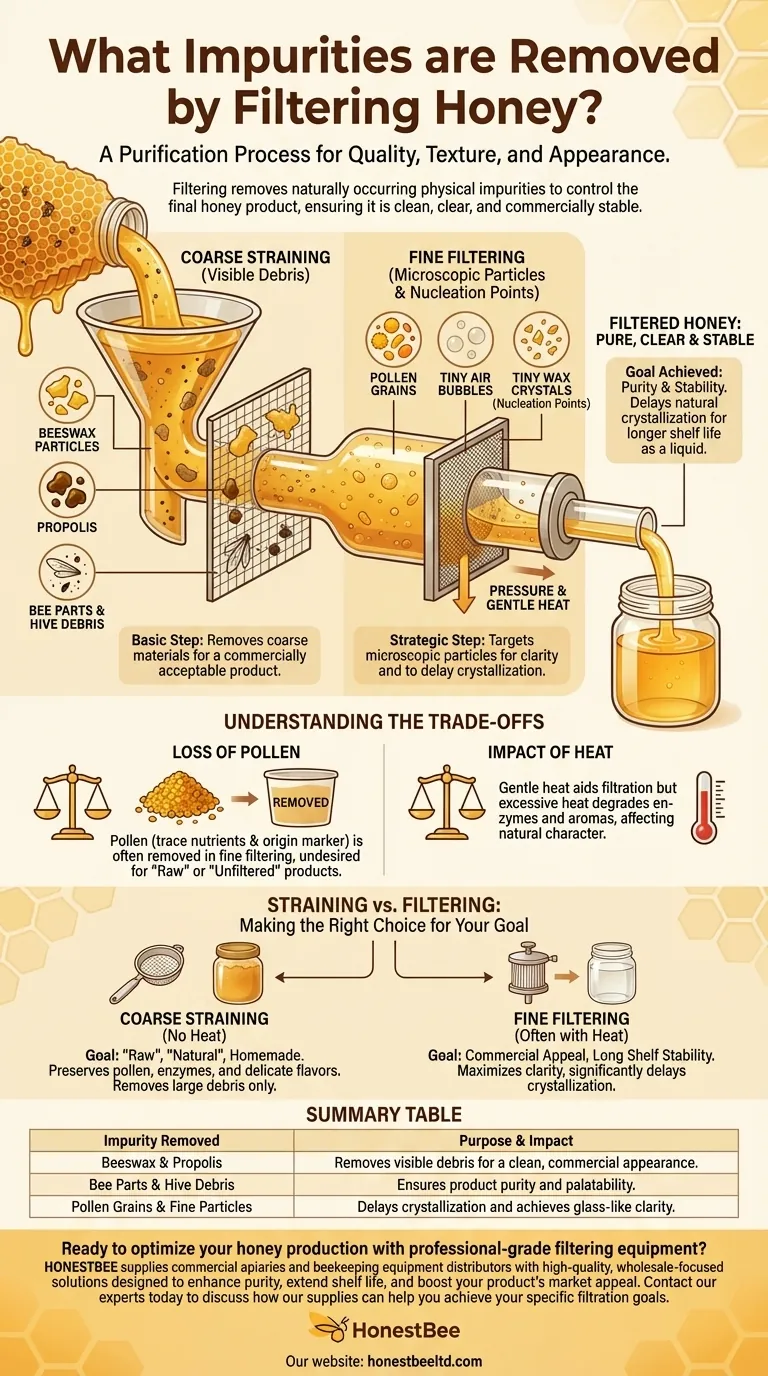

At its core, honey filtering is a purification process designed to remove a range of physical impurities that are naturally present after extraction from the honeycomb. The primary substances removed include visible debris like beeswax particles, propolis, parts of bees, and other foreign materials from the hive. This process ensures the honey is clean and visually clear.

The fundamental purpose of filtering is to control the final product's quality, texture, and appearance. It removes not only large, visible debris but also microscopic particles that can accelerate crystallization, ensuring the honey remains clear and liquid for longer, which is a key factor for marketability.

The Goal of Filtering: Achieving Purity and Stability

Filtering is more than just cleaning; it's a strategic step to create a specific type of honey product. The level of filtration directly impacts the honey's characteristics, from its clarity to its shelf life as a liquid.

Removing Visible Debris

The most basic function of filtering is to remove coarse materials left over from the extraction process. These are the impurities you could likely see with the naked eye.

Common examples include fragments of beeswax, bits of propolis (a resinous mixture bees produce), and unfortunate inclusions like bee parts or other hive debris. Removing these is the first step toward a commercially acceptable product.

Eliminating Fine Particles

Finer filtration methods go a step further, targeting microscopic particles. This is often done to achieve a perfectly clear, glass-like appearance.

These fine particles can include pollen grains and tiny air bubbles. While not harmful, their removal creates a product with a highly consistent texture and appearance that many consumers have come to expect from store-bought honey.

Preventing Unwanted Crystallization

One of the most significant technical reasons for fine filtering is to delay the natural process of crystallization, or granulation. Honey is a supersaturated sugar solution and will crystallize over time.

Fine particles, such as dust, pollen grains, and tiny wax crystals, act as nucleation points where sugar crystals can begin to form. By filtering these particles out, you significantly slow down the crystallization process, keeping the honey liquid and clear on the shelf for much longer.

Understanding the Trade-offs of Filtration

While filtering produces a clean and stable product, it is not without its compromises. The decision to filter, and to what degree, involves balancing purity against the potential loss of natural compounds.

The Loss of Pollen

Many consumers and natural food advocates consider pollen to be a valuable component of honey, containing trace nutrients. Fine filtering, by design, removes most of this pollen.

For honey producers who market their product as "raw" or "unfiltered," preserving the pollen content is a key selling point. It also serves as a definitive marker of the honey's floral and geographical origin.

The Impact of Heat

To make fine filtration efficient, honey is often gently heated to lower its viscosity, allowing it to pass through the filter more easily.

However, excessive heat can be detrimental. It can degrade the natural enzymes, such as diastase and invertase, and diminish the delicate aromas and flavors that make each type of honey unique. This is a critical trade-off between processing efficiency and preserving the honey's natural character.

Straining vs. Filtering

In the context of honey processing, these terms have distinct meanings. Straining typically involves passing honey through a mesh material to remove only the large, visible debris like wax and bee parts.

Filtering, on the other hand, is a more intensive process that forces honey, often under pressure, through much finer material to remove even microscopic particles like pollen. The choice between them defines the final product.

Making the Right Choice for Your Goal

The "best" method depends entirely on the desired characteristics of the final honey product. There is no single right answer, only the right approach for your specific objective.

- If your primary focus is commercial appeal and long shelf stability: Fine filtering after gentle heating is the standard to achieve maximum clarity and significantly delay crystallization.

- If your primary focus is a "raw" or "natural" product: Coarse straining without heat is the ideal method to remove large debris while preserving pollen, enzymes, and delicate flavors.

- If your primary focus is a clean, homemade product for personal use: A simple straining process is often sufficient to ensure the honey is clean and palatable without altering its natural state.

Ultimately, understanding what is removed during filtration empowers you to produce or select a honey that perfectly aligns with your quality standards and goals.

Summary Table:

| Impurity Removed | Purpose & Impact |

|---|---|

| Beeswax & Propolis | Removes visible debris for a clean, commercial appearance. |

| Bee Parts & Hive Debris | Ensures product purity and palatability. |

| Pollen Grains & Fine Particles | Delays crystallization and achieves glass-like clarity. |

Ready to optimize your honey production with professional-grade filtering equipment? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-quality, wholesale-focused solutions designed to enhance purity, extend shelf life, and boost your product's market appeal. Contact our experts today to discuss how our supplies can help you achieve your specific filtration goals—whether for raw, natural honey or crystal-clear commercial products.

Visual Guide

Related Products

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Professional Thermostatic Conical Honey Melter

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

People Also Ask

- What additional functions does a honey vacuum thickener have? Achieve a Stable, Commercial-Grade Product

- What is the typical drying performance of the disc dehumidifier-concentrator for honey? Optimize Your Honey Processing

- What are the benefits of motorized honey extractors? Save Time & Labor in Your Apiary

- What is required for the cooling system when using circulating water in the honey vacuum thickener? Essential Components for Efficient Processing

- What are the benefits of a honey concentrator? Elevate Your Honey Quality and Market Value