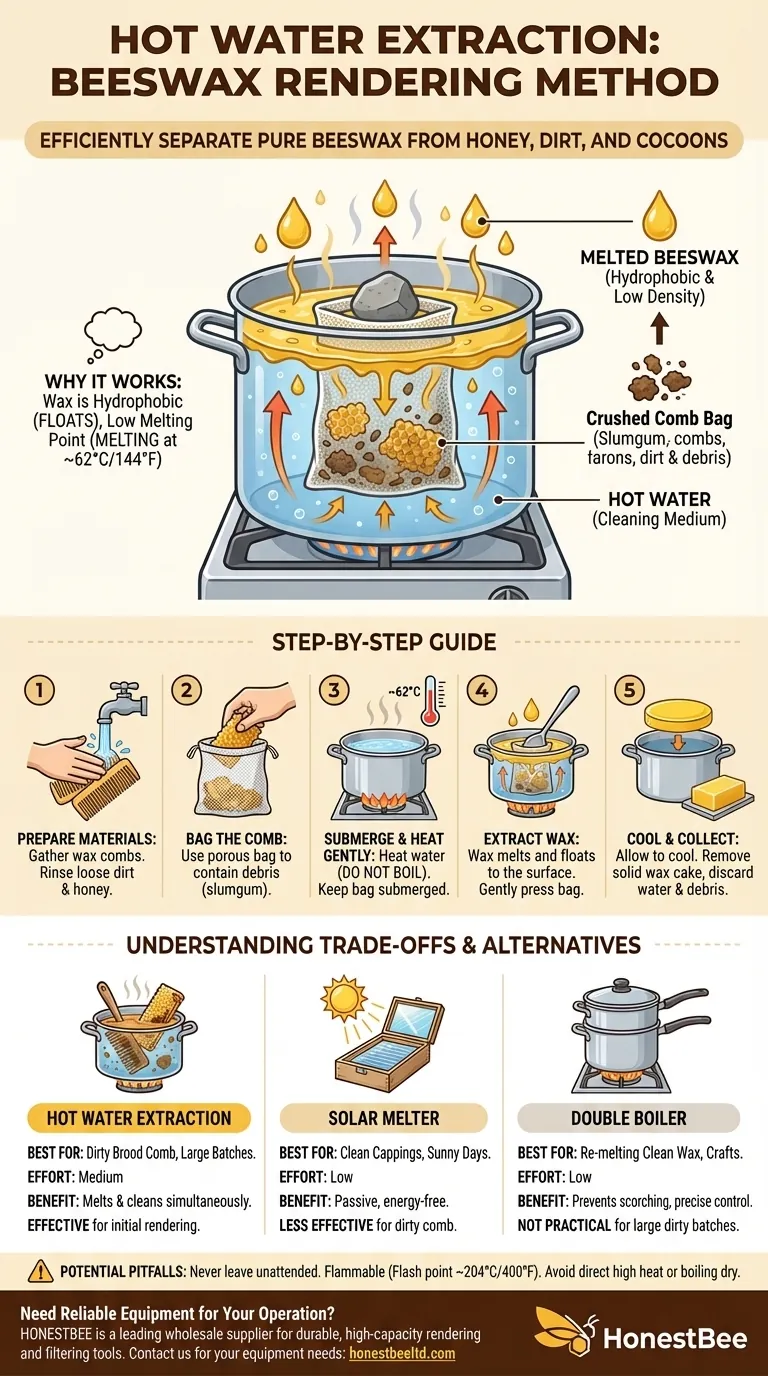

In short, hot water extraction is a method for rendering beeswax by submerging crushed combs in a bag within hot water. The heat melts the wax, which is lighter than water, causing it to escape the bag and float to the surface. As the water cools, the wax solidifies into a clean cake that can be easily collected, leaving debris and water behind.

The core challenge in processing beeswax is separating pure wax from honey, dirt, and old cocoons. Hot water extraction excels at this by using water as both a heating and a cleaning medium, making it a highly effective and accessible method for initial rendering.

The Principle: Why Hot Water Works

The effectiveness of this method rests on two simple physical properties of beeswax. Understanding them clarifies why each step in the process is necessary.

### Wax is Hydrophobic and Floats

Beeswax does not mix with water and is less dense. When melted in a pot of water, the liquid wax will naturally rise and form a distinct layer on the surface, cleanly separating from the water and any water-soluble impurities like residual honey.

### A Low Melting Point

Beeswax melts at a relatively low temperature, typically around 144-147°F (62-64°C). This means it can be liquefied in hot water well below boiling, which is crucial for safety and for preventing the wax from being scorched or discolored by excessive heat.

A Step-by-Step Guide to Hot Water Extraction

This method is straightforward and requires minimal specialized equipment, making it a popular choice for beekeepers of all scales.

### Step 1: Prepare Your Materials

First, gather your wax-filled combs. This can include honey cappings, burr comb, or old, dark brood comb. It's often helpful to give the combs a preliminary rinse with cool water to wash away loose dirt and excess honey.

### Step 2: Bag the Comb

Place the crushed comb into a porous bag. A burlap sack, a nylon stocking, or a purpose-made polypropylene bag works well. The goal is to create a container that holds back the solid debris (the "slumgum") while allowing the melted wax to escape through its mesh.

### Step 3: Submerge and Heat Gently

Place the bag in a large pot and cover it completely with water. Use a weight, like a clean rock, to keep the bag submerged. Heat the water on a stove or outdoor burner over medium-low heat, but do not let it boil. A gentle simmer is the maximum temperature you should aim for.

### Step 4: Extract the Wax

As the water heats, the wax will melt and seep through the bag, rising to the surface. You can gently press or squeeze the bag with a wooden spoon or other tool to help release more of the trapped wax.

### Step 5: Cool and Collect

Once you are satisfied that most of the wax has been released, turn off the heat and remove the bag of slumgum. Allow the pot to cool down completely, which can take several hours. As it cools, the layer of liquid wax on the surface will harden into a solid disk, which can then be lifted off the water.

Understanding the Trade-offs and Alternatives

While effective, hot water extraction is one of several methods. Choosing the right one depends on your resources, the quantity of wax you're processing, and your desired level of purity.

### Key Advantage: Effective for "Dirty" Wax

The primary strength of hot water rendering is its ability to both melt and clean wax simultaneously. It is particularly effective for processing old brood comb, which contains pupal cocoons and other debris that can be difficult to remove with other methods.

### Alternative 1: The Solar Melter

A solar melter uses the sun's heat to gently melt wax inside an insulated box. It's a passive, low-effort method that produces very clean wax from light-colored cappings. However, it is slow, completely dependent on sunny weather, and less effective on dark, dirty brood comb.

### Alternative 2: The Double Boiler

A double boiler melts wax gently using indirect heat, which is excellent for preventing scorching. This method is ideal for re-melting already cleaned blocks of wax for projects like making candles or balms. It is not practical for the initial rendering of large quantities of raw, dirty comb.

### Potential Pitfalls to Avoid

Never leave melting wax unattended. Beeswax is flammable and has a flash point of around 400°F (204°C). Using direct, high heat or allowing a pot to boil dry can create a significant fire hazard. Always use gentle, controlled heating.

Making the Right Choice for Your Goal

Your choice of rendering method should be guided by the type of comb you have and your end goal.

- If your primary focus is processing dirty brood comb or large batches: Use the hot water extraction method for its efficiency in both melting and cleaning.

- If your primary focus is passively rendering clean cappings with minimal effort: A solar melter is an excellent, energy-free choice when you have ample sun and time.

- If your primary focus is re-melting small amounts of clean wax for crafts: The double boiler provides the most control and safety for handling pure, filtered wax.

Ultimately, mastering beeswax rendering is about choosing the right tool for the job to safely transform your hive's byproducts into a valuable resource.

Summary Table:

| Feature | Hot Water Extraction | Solar Melter | Double Boiler |

|---|---|---|---|

| Best For | Dirty brood comb, large batches | Clean cappings, sunny days | Re-melting clean wax, crafts |

| Effort Level | Medium | Low | Low |

| Primary Benefit | Melts and cleans simultaneously | Passive, energy-free | Prevents scorching, precise control |

Need reliable equipment for your beeswax rendering operation? As a leading wholesale supplier to commercial apiaries and distributors, HONESTBEE provides the durable, high-capacity tools you need for efficient large-scale processing. From rendering pots to filtering supplies, our products are built for professional beekeeping demands. Contact our team today to discuss your equipment needs and discover how we can support your business's growth and efficiency.

Visual Guide

Related Products

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Professional Thermostatic Conical Honey Melter

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- What is the use of a comb foundation mill? Boost Honey Production with Strategic Hive Control

- What is the primary function of a beeswax flatting and embossing machine? Optimize Your Foundation Production

- What are the main components of a beeswax foundation sheet machine? A Guide to Efficient Production

- What materials are used in a silicone beeswax foundation embossing machine? Durable Steel and Alloy Construction

- What are the sequential stages of operation for a beeswax flatting and embossing machine? Master High-Quality Wax Sheets