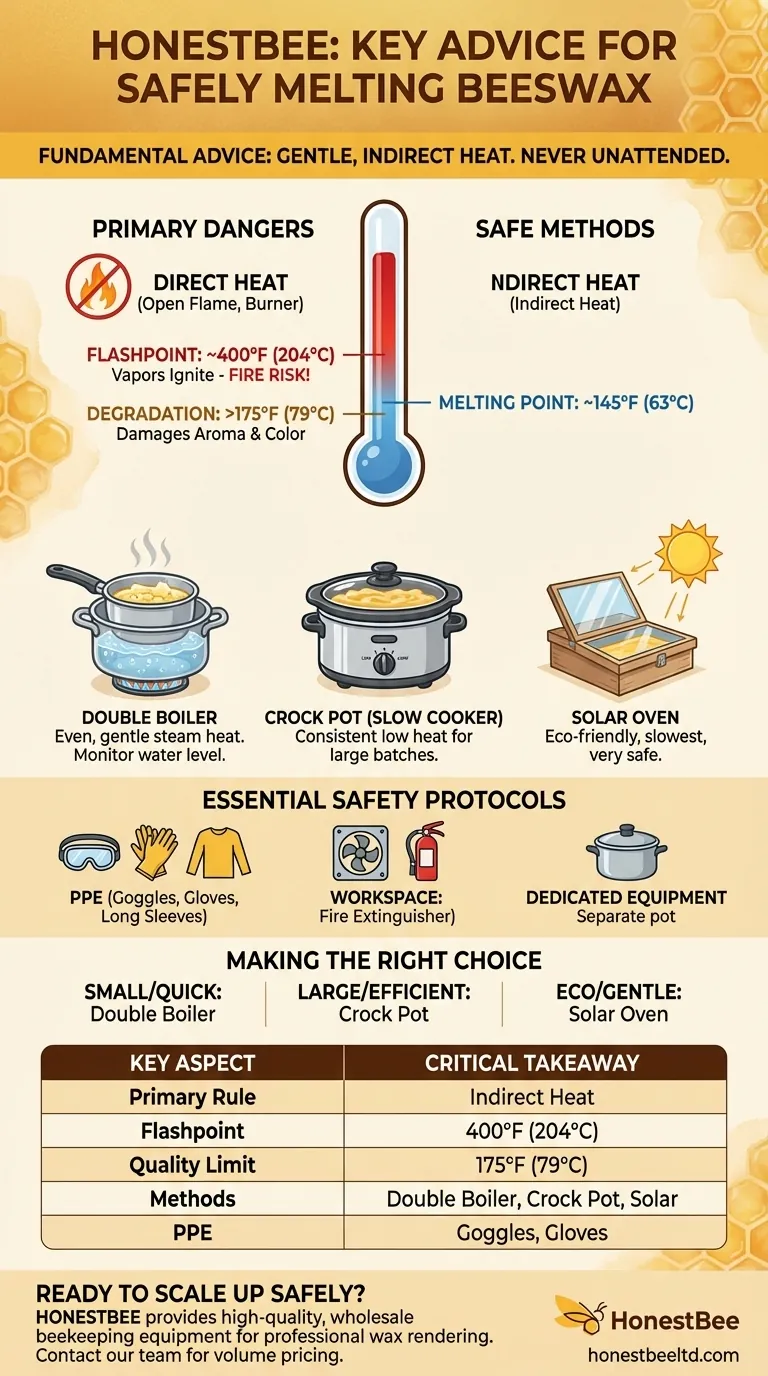

The fundamental advice for safely melting beeswax is to use gentle, indirect heat, never leave it unattended, and remove it from the heat source the moment it is fully melted. This simple protocol prevents the two primary dangers: fire and the degradation of the wax's natural properties.

The core principle of safely handling beeswax is temperature control. Because it is a flammable material with a relatively low flashpoint, all safety measures are designed to prevent it from ever reaching a dangerous temperature through the use of indirect and gentle heating methods.

Why Direct Heat is the Primary Danger

The most critical rule in handling beeswax is to avoid direct heat sources like an open flame or placing a pot directly on an electric burner. Understanding why this is so important is the key to preventing accidents.

The Risk of Fire

Beeswax is a flammable substance. While its melting point is low (around 145°F or 63°C), its flashpoint—the temperature at which its vapors can ignite—is approximately 400°F (204°C).

A direct heat source can easily create hot spots that push the wax past this temperature, creating a significant fire hazard.

The Degradation of Quality

Even well below the flashpoint, excessive heat damages the beeswax. Heating it above 175°F (79°C) can diminish its wonderful natural aroma, darken its color, and potentially break down its beneficial anti-microbial properties.

Gentle, indirect heat ensures the wax melts uniformly without being scorched or damaged.

The Safest Methods for Melting Beeswax

Choosing the right method is about creating a buffer between the intense heat source and the wax itself. The following methods are industry standards for their safety and effectiveness.

The Double Boiler Method

A double boiler is the classic and most accessible method. You can create one by placing a smaller pot (containing the wax) inside a larger pot that has a few inches of simmering water.

The steam from the water provides even, gentle heat that cannot exceed the boiling point of water (212°F or 100°C), keeping the wax well within a safe temperature range.

Crucially, you must monitor the water level in the bottom pot to ensure it doesn't boil away completely.

The Crock Pot (Slow Cooker) Method

A crock pot is an excellent choice for melting larger quantities of beeswax with minimal fuss. Its low, consistent heat is perfect for the task.

Simply place your beeswax in the crock pot and set it to the "low" setting. It will melt slowly and safely over a few hours.

The Solar Oven Method

For an eco-friendly and extremely gentle approach, a solar oven is a fantastic option.

This method uses the sun's energy to slowly melt the wax, making it impossible to scorch or overheat. It is the slowest method but also one of the safest.

Essential Safety Protocols to Never Skip

Beyond your heating method, establishing a safe workspace and using proper equipment are non-negotiable steps.

Use Personal Protective Equipment (PPE)

Hot wax can cause serious burns. Always wear safety goggles to protect your eyes, heat-resistant gloves, and a long-sleeved shirt to protect your skin from accidental splashes.

Prepare Your Workspace

Work in a well-ventilated area to avoid inhaling any fumes. Most importantly, keep a Class B fire extinguisher nearby and know how to use it. This is a critical precaution for any work involving flammable materials.

Use Dedicated Equipment

Beeswax is notoriously difficult to clean from pots and utensils. It is highly advisable to have a dedicated set of equipment used only for wax work. This prevents contamination of your kitchenware and makes cleanup far simpler.

Making the Right Choice for Your Goal

Your choice of method depends on the scale and needs of your project.

- If your primary focus is melting a small batch quickly: The double boiler method offers the most control and speed for projects like lip balms or salves.

- If your primary focus is processing a large block of wax with less supervision: The crock pot is the most efficient and practical solution.

- If your primary focus is maximum gentleness and an off-grid approach: The solar oven is an ideal, albeit slower, choice.

By respecting the properties of beeswax and using controlled, indirect heat, you can ensure a safe and successful outcome for any project.

Summary Table:

| Key Safety Aspect | Critical Takeaway |

|---|---|

| Primary Rule | Always use gentle, indirect heat. |

| Flashpoint Danger | Wax vapors can ignite at 400°F (204°C). |

| Quality Degradation | Heat above 175°F (79°C) damages aroma & color. |

| Recommended Methods | Double Boiler, Crock Pot, Solar Oven. |

| Essential PPE | Safety goggles, heat-resistant gloves. |

Ready to scale up your beekeeping operation safely?

For commercial apiaries and beekeeping equipment distributors, having the right, reliable supplies is key to efficient and safe wax rendering. HONESTBEE provides high-quality, wholesale-focused beekeeping equipment—from durable stainless steel melting tanks to protective gear—designed for professional use.

Let us equip you for success. Contact our wholesale team today to discuss your supply needs and volume pricing.

Visual Guide

Related Products

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- 10L Stainless Steel Honey Wax Press Extractor for Wax Cappings

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- What are the main components of a beeswax foundation sheet machine? A Guide to Efficient Production

- What are the benefits of using a machine to produce beeswax foundation sheets? Achieve Superior Hive Health & Efficiency

- What is the function of a beeswax foundation machine? Boost Hive Efficiency and Honey Production

- What are the cost-saving benefits of using fully automatic wax foundation machines? Maximize ROI for Commercial Apiaries

- What are the steps involved in preparing wax sheets for milling? Master Temperature Control for Perfect Foundation