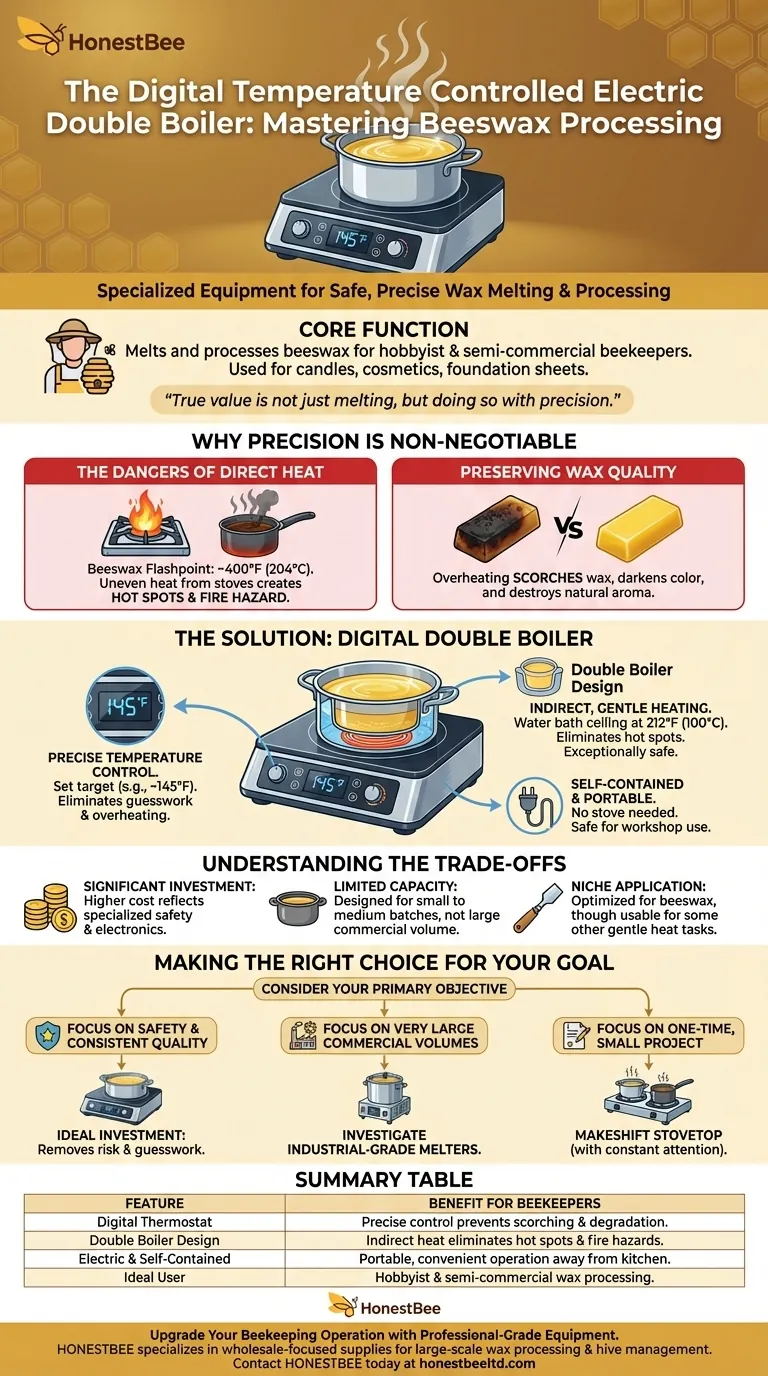

At its core, the digital temperature controlled electric double boiler is a specialized piece of equipment designed for melting and processing beeswax. Its primary users are hobbyist and semi-commercial beekeepers who require a safe and precise method for rendering wax cappings or preparing wax for candles, cosmetics, or foundation sheets.

This tool’s true value is not just melting wax, but doing so with precision. It solves the two biggest challenges of working with beeswax: the risk of fire from overheating and the degradation of wax quality from scorching.

Why Precise Control is Non-Negotiable for Wax

Simply melting wax in a pot on a stove is a high-risk activity. Understanding the properties of beeswax reveals why a specialized tool is a superior approach for both safety and quality.

The Dangers of Direct Heat

Beeswax is a flammable material with a flashpoint of approximately 400°F (204°C). Direct heat from a gas or electric stovetop is notoriously uneven and can easily create hot spots that exceed this temperature, creating a significant fire hazard.

Preserving Wax Quality

Even if you avoid a fire, overheating beeswax permanently damages it. Excessive heat will scorch the wax, darkening its color from a pleasant yellow to a dull brown and destroying its delicate, natural honey aroma.

The Role of Digital Temperature Control

A digital thermostat is the key to prevention. It allows you to set a precise target temperature—typically just above the melting point of beeswax (~145°F / 63°C)—and hold it there. This eliminates the guesswork and temperature fluctuations common with analog dials, ensuring the wax never gets hot enough to burn or degrade.

The Double Boiler Advantage

The double boiler design is a centuries-old technique for gentle heating. When combined with modern electric control, it creates an almost foolproof system for working with sensitive materials.

How a Double Boiler Works

The design consists of an inner chamber for the wax and an outer chamber for water. The electric element heats the water, and the steam from that hot water provides gentle, indirect heat to the inner chamber.

Eliminating Hot Spots Entirely

This method has a built-in safety ceiling. At standard atmospheric pressure, water cannot get hotter than its boiling point of 212°F (100°C). This means the surface heating your wax can never approach the wax's 400°F flashpoint, making the process exceptionally safe.

Self-Contained Convenience

An integrated electric unit removes the need for an external stove. This makes the process self-contained, more portable, and easier to manage in a workshop or garage environment, away from the kitchen.

Understanding the Trade-offs

While highly effective, this tool is not the perfect solution for every scenario. Objectivity requires acknowledging its limitations.

Initial Cost

A dedicated digital double boiler is a significant investment compared to using a simple pot on a hot plate. The cost reflects its specialized nature, safety features, and integrated electronics.

Limited Capacity

Most models available to hobbyists and semi-commercial users are designed for small to medium batches. They are not efficient for large-scale commercial apiaries that need to process hundreds of pounds of wax at once.

Niche Application

While it can be used for other tasks requiring gentle heat (like making soaps, lotions, or melting chocolate), its design and price point are optimized specifically for beeswax. If you do not work with wax, a less specialized device may be more cost-effective.

Making the Right Choice for Your Goal

To determine if this tool is right for you, consider your primary objective.

- If your primary focus is safety and consistent quality: This tool is the ideal investment, as it removes the risk and guesswork from processing beeswax.

- If your primary focus is processing very large, commercial volumes: You should investigate industrial-grade, high-capacity wax melters designed for bulk production.

- If your primary focus is a one-time, very small project: A makeshift double boiler on a stovetop can suffice, but it requires your constant, undivided attention to manage the temperature and mitigate risk.

Ultimately, this tool empowers you to transform raw beeswax into a high-quality product with unparalleled safety and consistency.

Summary Table:

| Feature | Benefit for Beekeepers |

|---|---|

| Digital Thermostat | Precise temperature control prevents wax scorching and degradation. |

| Double Boiler Design | Indirect, gentle heating eliminates hot spots and fire hazards. |

| Electric & Self-Contained | Portable, convenient operation away from a kitchen stove. |

| Ideal User | Hobbyist and semi-commercial beekeepers processing wax for candles, cosmetics, and foundations. |

Upgrade Your Beekeeping Operation with Professional-Grade Equipment

Are you a commercial apiary or beekeeping equipment distributor looking for reliable, high-quality supplies? HONESTBEE specializes in wholesale-focused operations, providing the durable tools you need for efficient, large-scale wax processing and hive management.

Contact HONESTBEE today to discuss your wholesale needs and discover how our equipment can enhance your productivity and product quality.

Visual Guide

Related Products

- 10L Stainless Steel Honey Wax Press Extractor for Wax Cappings

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

People Also Ask

- What is the role of constant temperature heating equipment in beeswax purification? Ensure Quality & Prevent Degradation

- What is a wax melter and what is its purpose in beekeeping? Essential Tools for Efficient Beeswax Recycling

- What types of beeswax melters are available for different scales of beekeeping? Solar vs. Electric Melters Compared

- How do professional beekeeping wholesalers support beeswax testing equipment? Key Ways Distribution Drives Innovation

- What is a wax melter used for in candle making? Achieve Professional, Scalable Production

- What are the three popular methods for melting beeswax? Safely Process Your Wax with Ease

- How does the use of water in a boiler or pan facilitate the gentle heating of beeswax? Preserve Color and Aroma

- What is the purpose of a solar wax melter? Turn Hive Scraps into Valuable Beeswax for Free