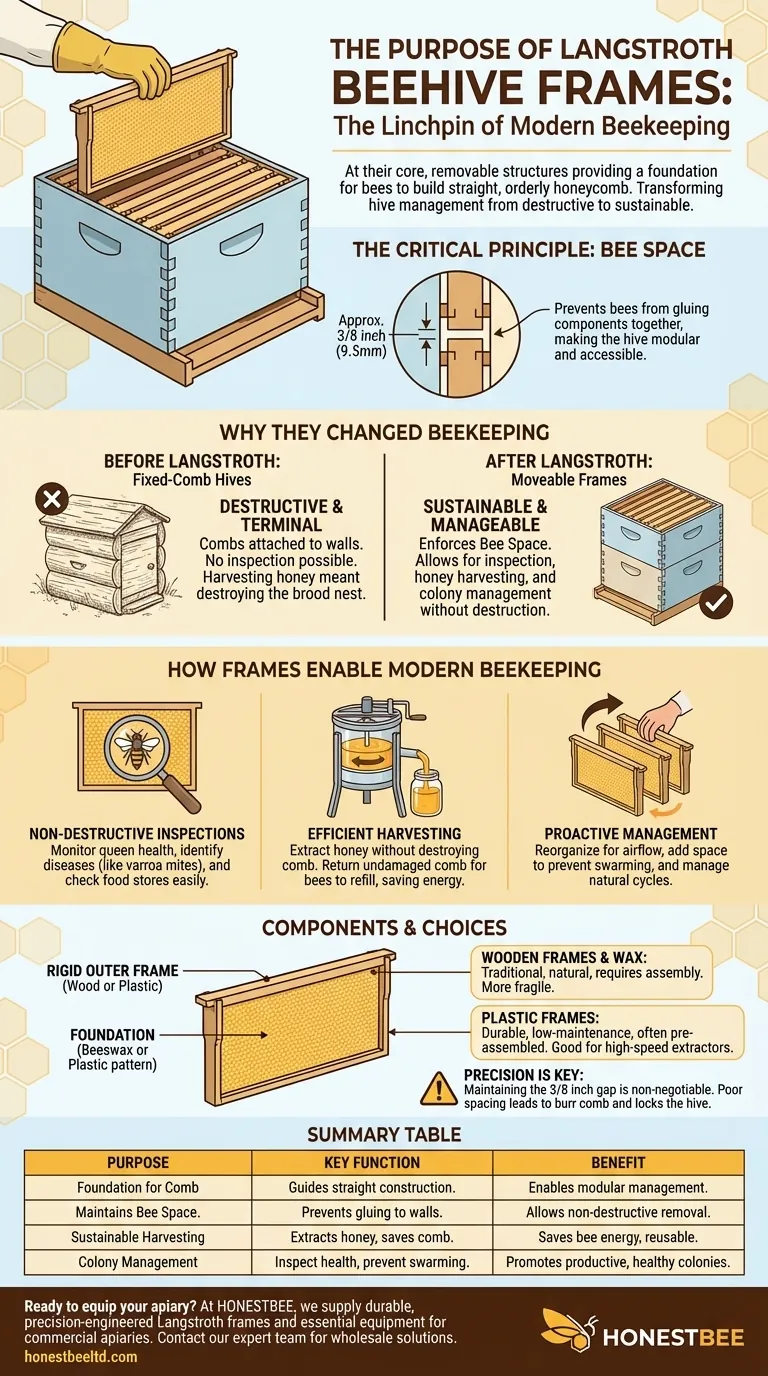

At their core, Langstroth beehive frames are removable structures that provide the foundation for bees to build their honeycomb. This simple innovation is the linchpin of modern beekeeping, transforming hive management from a destructive ordeal into a sustainable practice. By guiding bees to build straight, orderly combs within these self-contained "pages," frames allow beekeepers to inspect the colony and harvest honey without destroying the hive itself.

The true purpose of a beehive frame is not just to hold comb, but to enforce a critical principle known as "bee space." This precise gap around each frame prevents bees from gluing the combs to the hive walls, making the entire internal structure modular and accessible for the first time in beekeeping history.

The Problem Frames Were Designed to Solve

Before the Langstroth hive, beekeeping was often a terminal process. Bees were kept in simple boxes, logs, or woven skeps where they attached their comb directly to the interior walls, creating a single, interconnected structure.

The Era of Fixed-Comb Hives

In a fixed-comb hive, there was no way to inspect the colony for health or disease. The beekeeper had no visibility into the queen's egg-laying, the presence of pests, or the amount of food stores.

Harvesting honey meant cutting out large chunks of comb, a process that inevitably destroyed the brood nest and often resulted in the death of the colony. It was inefficient for the beekeeper and catastrophic for the bees.

Langstroth's Revolutionary Discovery

In 1851, Lorenzo Langstroth observed that if a gap of approximately 3/8 of an inch was left between surfaces within the hive, bees would not build comb or seal it with propolis. They would leave it open as a passageway.

This phenomenon, now called bee space, is the fundamental principle that makes the modern hive possible. The Langstroth frame is engineered to perfectly maintain this space between each frame and between the frames and the hive box walls.

How Frames Enable Modern Beekeeping

By leveraging bee space, frames grant the beekeeper unprecedented access and control, turning them from a honey harvester into a true colony manager.

Non-Destructive Hive Inspections

The ability to lift out a single frame is the most significant advantage. A beekeeper can examine the comb to check the queen's health, identify the presence of eggs and developing brood, and spot early signs of diseases or pests like the varroa mite.

This regular monitoring is essential for maintaining a healthy, productive colony year after year.

Efficient and Sustainable Harvesting

Frames allow for the removal of honey without destroying the comb. Beekeepers can take a frame filled with honey, uncap the wax, and use a centrifugal extractor to spin the honey out.

The empty, undamaged comb is then returned to the hive. This saves the bees an immense amount of energy, as producing wax is a resource-intensive process. They can immediately begin refilling the existing cells instead of having to rebuild from scratch.

Proactive Colony Management

Frames give beekeepers tools to manage the colony's natural cycles. They can add empty frames to give the queen more room to lay eggs, which helps prevent the colony from swarming.

Beekeepers can also reorganize frames, moving brood or honey stores as needed, or remove frames to improve airflow during hot weather. This level of control is impossible in a fixed-comb hive.

Understanding the Components and Trade-offs

A frame is more than just a wooden or plastic rectangle; it's part of a system that includes a foundation, which guides the bees' construction.

The Frame and Foundation Partnership

The frame provides the rigid outer structure. Inside it, beekeepers typically place a foundation—a thin sheet of beeswax or plastic embossed with the hexagonal pattern of honeycomb cells.

This foundation serves as a guide, encouraging bees to build straight comb with uniform cell sizes. This ensures the comb is contained entirely within the frame's dimensions, preserving the critical bee space.

Material Choices: Wood vs. Plastic

Wooden frames are traditional and what many people picture. They are often paired with pure beeswax foundation, which is seen as a more natural option. However, they require assembly and can be more fragile during honey extraction.

Plastic frames are a durable, low-maintenance alternative. They often come as a single molded piece with the foundation pattern built-in and are typically coated in beeswax to encourage the bees to accept them. Their rigidity is a significant advantage in high-speed extractors.

The Non-Negotiable Need for Precision

The entire Langstroth system fails if the bee space is not maintained. Poorly built equipment, warped frames, or improper hive assembly can lead to bees building burr comb in the incorrect gaps.

This rogue comb connects frames to each other or to the hive box, effectively locking the components together and reverting the hive back to a fixed-comb state that is difficult or impossible to inspect.

Making the Right Choice for Your Goal

The type of frame you use can be tailored to your specific beekeeping philosophy and objectives.

- If your primary focus is maximum honey production: Fully-drawn plastic frames are highly efficient, as their durability withstands fast extraction and their pre-built nature saves bee energy for honey-making.

- If your primary focus is natural beekeeping: Wooden frames with foundationless guides or pure beeswax foundation allow bees to build their own comb with natural cell sizing.

- If your primary focus is simplicity for a new beekeeper: Pre-assembled, wax-coated plastic frames are the easiest entry point, as they require no construction and provide a strong, reliable guide for your first colony.

Ultimately, understanding that frames are a tool for managing space is the first step toward becoming a thoughtful and successful beekeeper.

Summary Table:

| Purpose | Key Function | Benefit to Beekeeper |

|---|---|---|

| Foundation for Comb | Guides bees to build straight, orderly honeycomb. | Enables modular hive management. |

| Maintains Bee Space | Prevents bees from gluing comb to hive walls (approx. 3/8 inch gap). | Allows for non-destructive frame removal and inspection. |

| Sustainable Harvesting | Allows honey to be extracted without destroying the comb. | Saves bee energy; comb can be reused. |

| Colony Management | Enables beekeepers to inspect health, reorganize, and prevent swarming. | Promotes a healthy, productive colony year after year. |

Ready to equip your apiary with the right foundation for success?

At HONESTBEE, we supply durable, precision-engineered Langstroth beehive frames and essential beekeeping equipment to commercial apiaries and distributors. Our wholesale-focused operations ensure you get the reliable, high-quality supplies needed to maintain healthy colonies and maximize honey production.

Contact our expert team today to discuss your specific needs and discover how HONESTBEE can support your beekeeping success.

Visual Guide

Related Products

- Professional In-Hive Bee Feeder HONESTBEE Frame for Beekeeping

- Mini Desktop Bee Hive Frame Forming Making Machine

- Professional Bee Frame Wiring Tool with Integrated Tensioning System by HONESTBEE

- Plastic Bee Frame Beekeeping Hive Frames for Wholesale

- JZBZ Langstroth Queen Rearing Frame for Beekeeping

People Also Ask

- Are frame feeders good? Maximize Your Hive's Health with the Right Feeding Strategy

- Why is an internal hive feeder necessary? Essential Colony Management for Summer & Winter Dearth Periods

- How should the round hive top feeder be positioned? Master Internal Feeding for Stronger Colonies

- What is the primary function and design advantage of an integrated top feeder? Boost Hive Productivity and Precision

- What is the primary function of internal hive feeders? Precision Feeding for Commercial Apiaries and Assessments