To make your own beeswax foundation, you will need several pieces of miscellaneous equipment beyond the foundation mill itself. This includes a source for hot water, specific tools for cutting, boards for dipping and sizing, and supplies for cleaning the mill and handling the finished wax sheets. Essential items are a pizza cutter, custom-sized masonite boards for templates, a scrub brush, and a specific type of dish soap to act as a release agent.

Making your own foundation is a hands-on process where commercial kits are rare. Success hinges not on the main embossing mill, but on assembling the right supporting cast of tools for melting, forming, cutting, and cleaning the wax at each stage of the workflow.

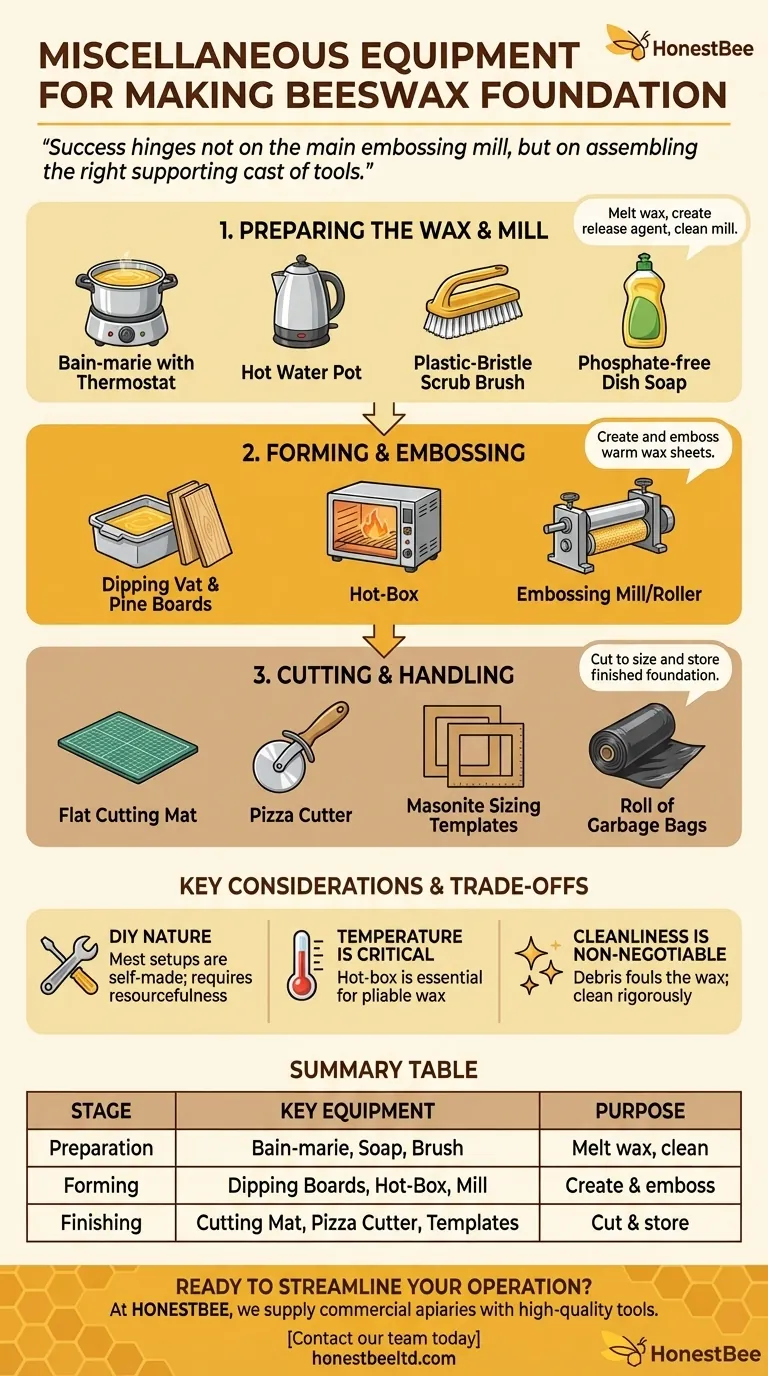

The Foundation-Making Workflow: Equipment by Stage

Creating foundation is a multi-step process, and different tools are required for each phase. Thinking about the equipment in terms of its role in the workflow—from raw wax to finished sheet—clarifies what you need and why.

Preparing the Wax and Mill

Before you can form a single sheet, you must prepare your wax and your equipment.

- Wax Melter: You need a dedicated vat or bain-marie with a thermostat to melt your filtered beeswax and hold it at a consistent temperature.

- Hot Water Source: An instant hot-water pot or a dedicated water bath is critical for creating the soapy release agent needed to keep wax from sticking to the mill.

- Cleaning Supplies: A plastic-bristle scrub brush is used to clean the delicate surface of the embossing mill.

- Release Agent: Use phosphate-free, biodegradable liquid dish soap mixed with hot water. This prevents wax contamination and ensures a clean release from the mill without damaging the equipment.

Forming and Embossing the Wax Sheets

This is the core of the process, where liquid wax is transformed into a patterned sheet.

- Dipping Vats & Boards: You need a vat for dipping and a separate one for holding your pine dipping boards. These smooth boards are dipped into the hot wax to create thin, plain wax sheets.

- Hot-Box: A simple heated box is often necessary for gently warming the plain wax sheets before they are run through the mill. Cold wax is brittle and will crack; properly warmed wax is pliable and takes the hexagonal impression perfectly.

- Embossing Mill/Roller: This is the primary piece of equipment that imprints the foundation pattern onto your warmed wax sheets.

Cutting and Handling the Final Product

Once the foundation is embossed, it must be cut to size and stored properly.

- Cutting Station: A flat cutting board or mat provides a safe, clean surface for trimming the foundation.

- Cutting Tools: A round pizza cutter or a sharp knife is the preferred tool for cleanly and quickly cutting the foundation sheets.

- Sizing Templates: Thin masonite boards cut to specific frame sizes (e.g., 8" x 16 1/2" for deep frames) are used as templates. You lay them on the foundation and cut around them for perfect, consistent sizing.

- Separating Sheets: A paper-cutter is useful for making sheets of paper that are placed between finished foundation sheets to prevent them from sticking together in a stack.

- Storage: Rolls of plastic garbage bags are used to store stacks of finished foundation, protecting them from dust, pests, and damage.

Understanding the Trade-offs and DIY Nature

Beekeeping rewards resourcefulness, and foundation-making is a prime example. Understanding the common challenges will help you prepare for them.

Most Setups are Self-Made

Very few complete, off-the-shelf foundation-making kits exist. Beekeepers are expected to be resourceful, building their own dipping vats, hot-boxes, and cutting stations. This allows for customization but requires a DIY mindset.

Temperature is a Critical Variable

Success is highly dependent on temperature control. If the dipping wax is too hot, the sheets will be too thin. If the sheets are too cold when they enter the mill, they will crack. The hot-box is not an optional accessory; it is a critical component for achieving pliable wax.

Cleanliness is Non-Negotiable

Any debris on your dipping boards, in your wax, or on your embossing mill will be permanently embedded in your final product. Using the wrong soap can leave a residue that fouls the wax. Meticulous cleaning at every step is essential for producing high-quality foundation.

Assembling Your Foundation-Making Toolkit

Your equipment choices should align with your scale and goals.

- If your primary focus is efficiency and consistency: Invest in a thermostat-controlled bain-marie for melting wax and build a dedicated hot-box to ensure your wax sheets are always at the perfect temperature for embossing.

- If you are starting on a small scale: Begin with a simple pot-in-pot double boiler, basic dipping boards, and a pizza cutter. This allows you to learn the process without a large upfront investment.

- If your priority is pristine, high-quality foundation: Pay closest attention to your cleaning protocol. Use only phosphate-free, biodegradable soap and ensure your mill and all surfaces are spotless before you begin.

By assembling these miscellaneous but critical tools, you transform a challenging craft into a manageable and rewarding part of your beekeeping practice.

Summary Table:

| Stage | Key Equipment | Purpose |

|---|---|---|

| Preparation | Bain-marie, Hot Water Pot, Scrub Brush, Phosphate-free Soap | Melt wax, create release agent, clean mill |

| Forming | Dipping Vats, Pine Boards, Hot-Box, Embossing Mill | Create and emboss warm wax sheets |

| Finishing | Cutting Mat, Pizza Cutter, Masonite Templates, Garbage Bags | Cut sheets to size and store finished foundation |

Ready to streamline your beekeeping operation?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the high-quality, durable tools needed for every stage of production—including foundation making. Our wholesale-focused operations ensure you get reliable equipment at competitive prices.

Contact our team today to discuss your specific needs and discover how we can support your success.

Visual Guide

Related Products

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- Professional 3-Bar Frame Grip with Integrated Hive Tool

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- Food Grade Plastic bee Foundation for Bee Frames

People Also Ask

- What is the primary function of embossed wax? Boost Bee Colony Induction & Speed Up Hive Colonization

- What are the advantages of beeswax and plastic foundations? Maximize Your Apiary's Efficiency

- How do high-quality comb foundations contribute to honeybee colony productivity? Maximize Your Spring Yield

- What are the primary commercial and industrial applications for harvested beeswax? Maximize Your Hive Product Potential

- What is the significance of standardized Hive Cells in large-scale commercial honey production? Unlock Scalability

- What is the purpose of the foundation in a Langstroth hive? A Guide to Straight Comb and Hive Management

- What is the significance of providing organic foundation for bee colonies? Achieve High-Purity Beeswax Standards

- What is the purpose of using natural beeswax in bee hives? Boost Your Colonization Rates and Honey Production