When using a table saw, your primary safety precautions involve understanding and preventing kickback, keeping your hands far from the blade, and ensuring the saw is properly equipped and calibrated. For a project like a hive-top feeder, which involves cutting relatively small pieces, this means you must use a riving knife, a blade guard, and push sticks or blocks for every cut. Never attempt to cut a piece of wood without a way to guide it securely.

A table saw does not forgive mistakes. Your safety is not dependent on a single tip, but on a systematic process of controlling the tool, controlling the workpiece, and controlling yourself. Adopting this mindset is the most important precaution you can take.

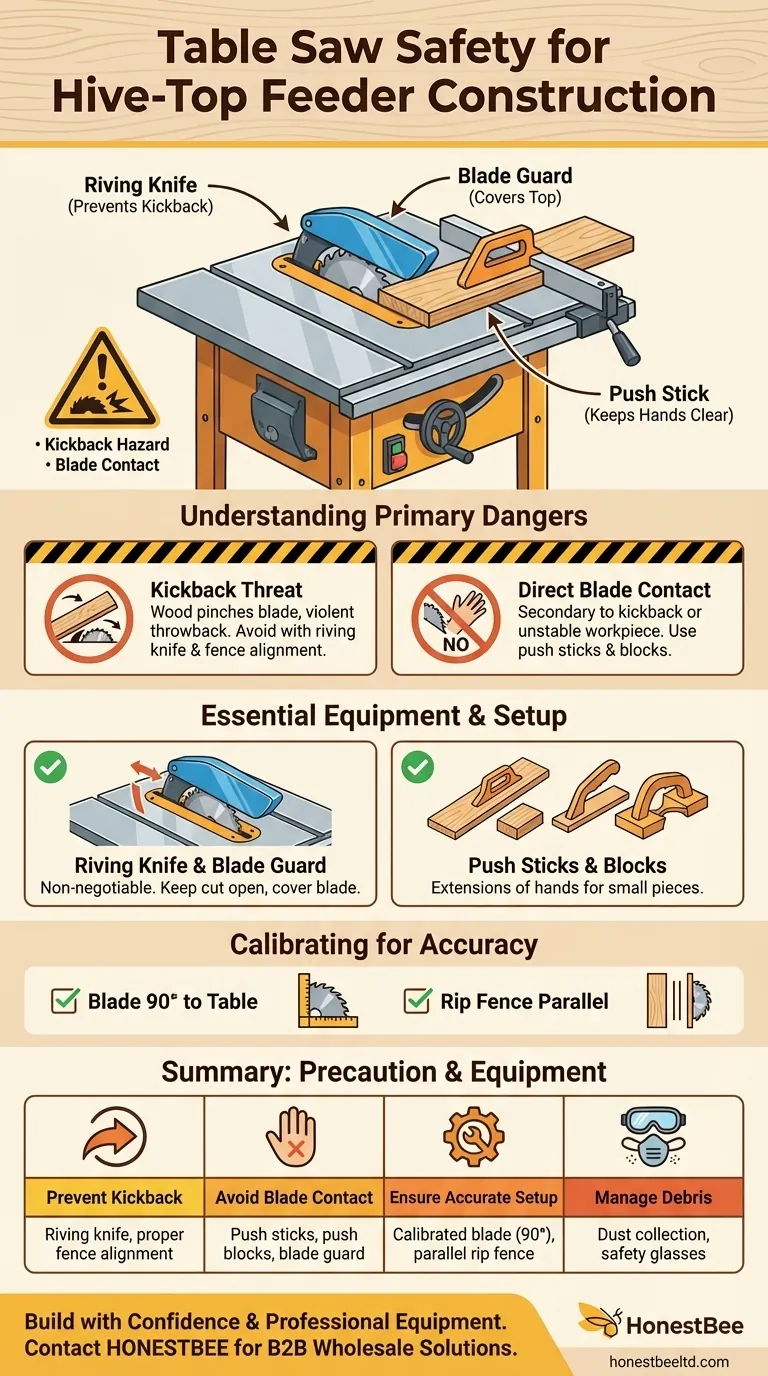

Understanding the Primary Dangers

To operate a table saw safely, you must first respect its dangers. The precautions are not arbitrary rules; they are direct countermeasures to specific, predictable hazards.

The Threat of Kickback

Kickback is the most common cause of serious table saw injuries. It occurs when the workpiece is suddenly and violently thrown back toward the operator at high speed.

This happens when the wood pinches the back of the spinning blade or when it twists and catches the blade's rising teeth. The force is powerful enough to cause severe impact injuries and can pull your hand into the blade as you lose balance.

Direct Blade Contact

The second major danger is direct contact with the spinning blade. This often happens as a secondary event following kickback, or when an operator's hands get too close to the blade while managing a small or unstable workpiece.

Using tools like push sticks and push blocks is not optional; it is the only reliable way to keep your fingers a safe distance from the blade.

Wood Dust and Debris

While less immediate, airborne wood dust is a serious respiratory hazard over time. Similarly, flying chips and small offcuts can cause significant eye injuries.

Proper dust collection and wearing appropriate Personal Protective Equipment (PPE) are essential for your long-term health and immediate safety.

Essential Safety Equipment and Setup

A properly configured saw is your first line of defense. Before making any cut for your hive-top feeder, ensure your equipment is in place and correctly adjusted.

The Non-Negotiable Riving Knife and Blade Guard

The riving knife is a metal plate that sits just behind the saw blade. Its sole purpose is to keep the cut open, preventing the wood from pinching the blade and causing kickback. It should be as close to the blade as possible.

The blade guard is a plastic or metal hood that covers the top of the blade. It prevents accidental contact from above and helps contain dust and debris. Do not operate the saw without these two components in place.

The Role of Push Sticks and Push Blocks

For a project with smaller components like a hive feeder, your hands will naturally get closer to the blade. Push sticks and push blocks are essential extensions of your hands.

Use a push stick to push narrow pieces through the end of the cut. Use a push block for wider pieces to apply even, downward pressure, keeping the wood flat on the table and your hands safely away.

Calibrating Your Saw for Accuracy

An inaccurate saw is an unsafe saw. Before you begin, confirm two key alignments:

- Blade is 90 degrees to the table. An angled blade can behave unpredictably.

- Rip fence is perfectly parallel to the blade. A fence that toes-in can pinch the wood, guaranteeing kickback.

Always test your settings on a piece of scrap wood first. This confirms your measurements and allows you to feel how the cut will behave before committing to your project material.

Understanding the Trade-offs and Common Pitfalls

Knowing the rules is one thing; applying them consistently requires understanding why people are tempted to break them.

The Temptation to Remove Safety Guards

Some advanced woodworking cuts may require removing the blade guard. Building a hive-top feeder does not involve any of these cuts. Operators sometimes remove guards because they feel they get in the way, but doing so removes your primary protection against blade contact and increases your risk exponentially.

Rushing the Process

Building bee equipment can be exciting, but rushing leads to mistakes. A simple measurement error can lead to frustration, which in turn can lead to making a "quick, risky cut" to fix it.

Slow down. Work deliberately. The principle of "measure twice, cut once" is as much a safety rule as it is an accuracy rule. A calm and focused operator is a safe operator.

Never Use the Miter Gauge and Rip Fence Together

This is a classic and critical mistake. Using both guides simultaneously to make a crosscut on a piece of wood will trap the offcut between the blade and the fence. This trapped piece has nowhere to go and will be launched back as violent kickback.

If you need to make repeatable crosscuts, use your miter gauge and attach a stop block to your rip fence, ensuring the workpiece is clear of the stop block before it contacts the blade.

Making the Right Choice for Your Goal

Your approach to safety should be tailored to your experience level and the task at hand.

- If you are new to the table saw: Your primary focus should be on mastering the basics with scrap wood. Practice rip cuts and crosscuts using all safety equipment until the process feels smooth and controlled.

- If you are making multiple feeders: Your focus should be on repeatability and efficiency. Use jigs, a crosscut sled, and stop blocks to make identical cuts safely without measuring each one individually.

- If any cut feels awkward or unsafe: Stop immediately and re-evaluate. There is always a safer way to achieve the cut, whether by using a different technique, building a simple jig, or using another tool.

Ultimately, consistent safety practices will enable you to work with greater precision, confidence, and enjoyment.

Summary Table:

| Safety Precaution | Purpose | Key Equipment |

|---|---|---|

| Prevent Kickback | Stops wood from pinching blade and being thrown back | Riving knife, proper fence alignment |

| Avoid Blade Contact | Keeps fingers safe during small cuts | Push sticks, push blocks, blade guard |

| Ensure Accurate Setup | Creates predictable, safe cutting behavior | Calibrated blade (90°), parallel rip fence |

| Manage Debris | Protects against long-term respiratory and eye injuries | Dust collection, safety glasses |

Build Your Hive-Top Feeders with Confidence and Professional-Grade Equipment

Constructing durable, precise beekeeping equipment starts with the right tools and a commitment to safety. At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the high-quality, reliable supplies needed for efficient and safe production.

Whether you're building a single feeder or outfitting a large-scale operation, having the right tools makes all the difference. Contact our expert team today to discuss your wholesale needs and discover how HONESTBEE can support your business with durable equipment that meets the demands of professional beekeeping.

Visual Guide

Related Products

- Beehive Machine Double End Saw for Precision Hive Component Manufacturing

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Customizable Honey Uncapping Fork with Adjustable Tine Options

- Honeycomb Uncapping Knife for Apiculture

- Extra-Wide All-Stainless Steel Honey Uncapping Fork with T-Handle

People Also Ask

- Why is modern hive construction a highly sought-after skill? Master the Art of Cost-Effective Apiary Expansion

- How do standardized hives improve colony productivity in adverse environments? Precision Gear for Commercial Yields

- Why is the adoption of hive-making machines considered a strategic move? Drive Industry Growth & Industrial Scale

- What role does industrial beehive manufacturing machinery play? Scale Your Commercial Apiary with Precision

- How do standardized hive-making machines support consistency in honey bee breeding experiments? Precision for Research