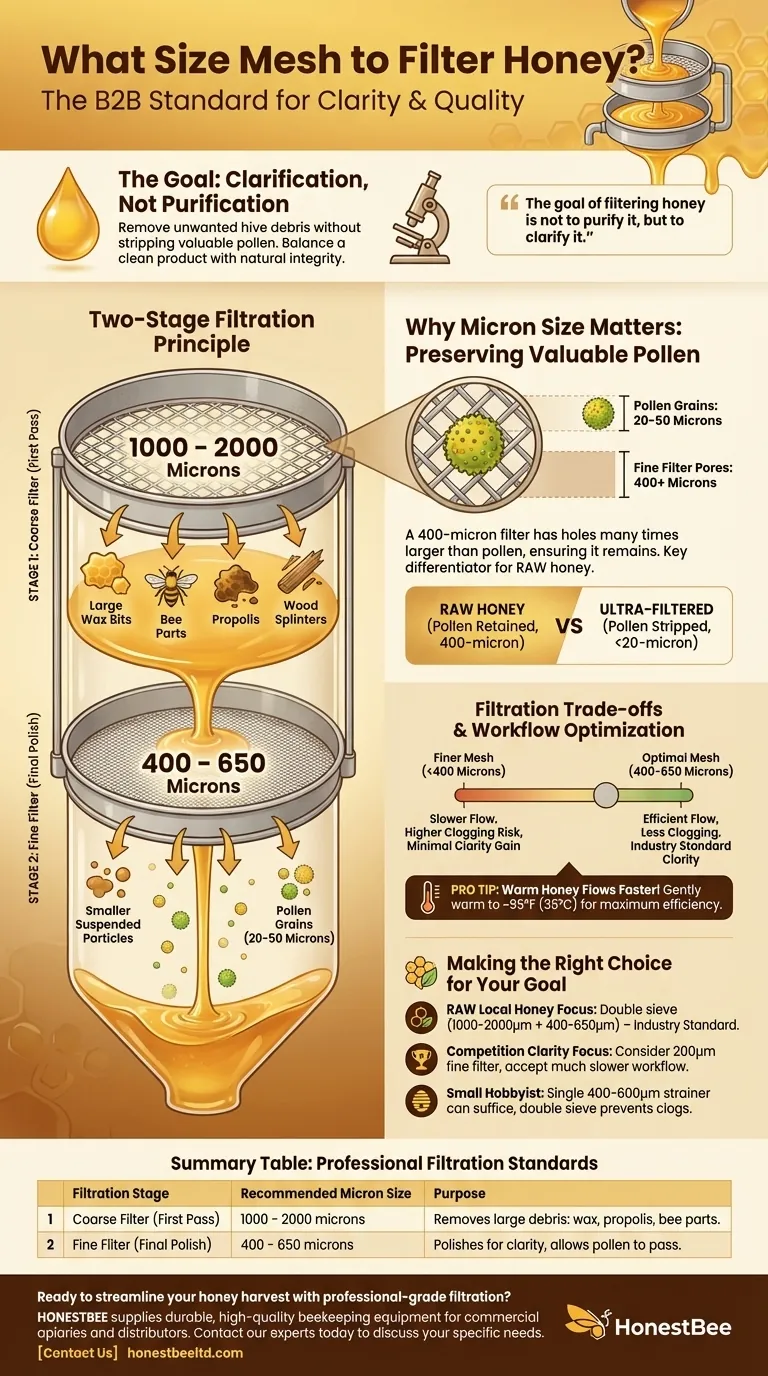

For filtering honey, the standard approach is a two-stage system using a coarse mesh of approximately 1000-2000 microns stacked on top of a fine mesh of 400-650 microns. This combination effectively removes visible debris like wax and bee parts while preserving the beneficial pollen that consumers expect in local, raw honey.

The goal of filtering honey is not to purify it, but to clarify it. The right equipment removes unwanted hive debris without stripping the valuable pollen, striking a critical balance between a clean product and a natural one.

The Two-Stage Filtration Principle

Using a single, very fine filter is inefficient. It will quickly become clogged with larger pieces of wax and debris, slowing your entire process to a halt. A two-stage system is the professional standard for this reason.

The Coarse Filter (The First Pass)

The top, coarser filter acts as the primary strainer. Its job is to catch the big pieces.

This includes larger bits of beeswax, propolis, wood splinters from the hive, and any unfortunate bee parts. Common sizes range from 1000 to 1875 microns.

The Fine Filter (The Final Polish)

The bottom, finer filter does the final polishing work. It catches smaller suspended particles that made it through the first stage.

This is the critical filter that determines the final clarity. A mesh size between 400 and 650 microns is ideal. This is fine enough to produce beautifully clear honey but large enough to allow pollen grains to pass through freely.

Why Micron Size Is the Deciding Factor

Understanding the measurements involved helps clarify why this system works so well. A micron is a unit of measurement, and a lower micron number means smaller holes in the mesh.

Preserving Valuable Pollen

Pollen grains are microscopic, but they are still large enough to be caught by extremely fine filters. Most pollen is between 20-50 microns.

A 400-micron filter has holes that are many times larger than a pollen grain, ensuring it remains in the final product. This is a key differentiator between raw, local honey and commercially ultra-filtered honey, which often has pollen removed.

Removing Unwanted Debris

The two-stage filtering process is designed to remove debris that is visible to the naked eye and undesirable in the final product.

The system effectively catches common impurities without compromising the honey's natural composition.

Understanding the Trade-offs

Choosing a filter system isn't just about picking a number; it's about understanding the consequences of that choice on your honey and your workflow.

Filtration Speed vs. Clarity

Using a mesh finer than 400 microns (such as a 200-micron filter) will result in slightly clearer honey. However, it will also dramatically slow down the filtering process and is much more prone to clogging.

For most applications, the minimal gain in clarity is not worth the significant increase in processing time.

The Critical Role of Temperature

Honey's viscosity is highly dependent on temperature. Warm honey flows much faster and is significantly easier to filter than cold honey.

Attempting to filter cool, thick honey, even with the correct mesh sizes, will be a slow and frustrating experience. Gently warming your honey to around 95°F (35°C) will make the process far more efficient.

"Raw" vs. Ultra-Filtered

Filtering honey with a 400-micron mesh does not change its classification as "raw." The term generally refers to honey that has not been pasteurized (heated to high temperatures) or ultra-filtered.

Ultra-filtration uses meshes below 20 microns, which actively strips pollen and other microscopic compounds, fundamentally altering the honey.

Making the Right Choice for Your Goal

Your ideal setup depends on your final objective.

- If your primary focus is classic "raw" local honey: A double sieve with a 1000-2000 micron coarse filter and a 400-650 micron fine filter is the perfect industry-standard choice.

- If your primary focus is maximum clarity for honey competitions: You might consider a 200-micron fine filter, but be prepared for a much slower workflow and ensure your honey is adequately warmed.

- If you are a small hobbyist processing a single hive: A single 400 or 600-micron strainer can suffice, but using a double-sieve system from the start will save you time and prevent clogs.

Ultimately, selecting the right mesh allows you to produce clean, beautiful honey that retains all of its natural integrity.

Summary Table:

| Filtration Stage | Recommended Micron Size | Purpose |

|---|---|---|

| Coarse Filter (First Pass) | 1000 - 2000 microns | Removes large debris like wax, propolis, and bee parts. |

| Fine Filter (Final Polish) | 400 - 650 microns | Polishes honey for clarity while allowing pollen to pass through. |

Ready to streamline your honey harvest with professional-grade filtration?

HONESTBEE supplies the durable, high-quality beekeeping supplies and equipment that commercial apiaries and distributors trust. Our wholesale-focused operations ensure you get the reliable two-stage sieve systems and other essential tools you need for an efficient, high-yield season.

Contact our experts today to discuss your specific needs and discover how we can support your beekeeping success.

Visual Guide

Related Products

- 10L Stainless Steel Electric Honey Press Machine

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

People Also Ask

- What are the key features of the stainless steel honey press? Maximize Yield & Guarantee Purity

- What are the benefits of the screw design in a stainless steel honey pump? Preserve Honey Quality and Integrity

- What are the advantages of using industrial-grade stainless steel honey extractors vs. traditional methods?

- What are the main differences between centrifugal extractors and honey presses? A Guide for Commercial Apiaries

- What are the unique characteristics of honey presses? Maximize Honey Yield for Small-Scale Beekeeping