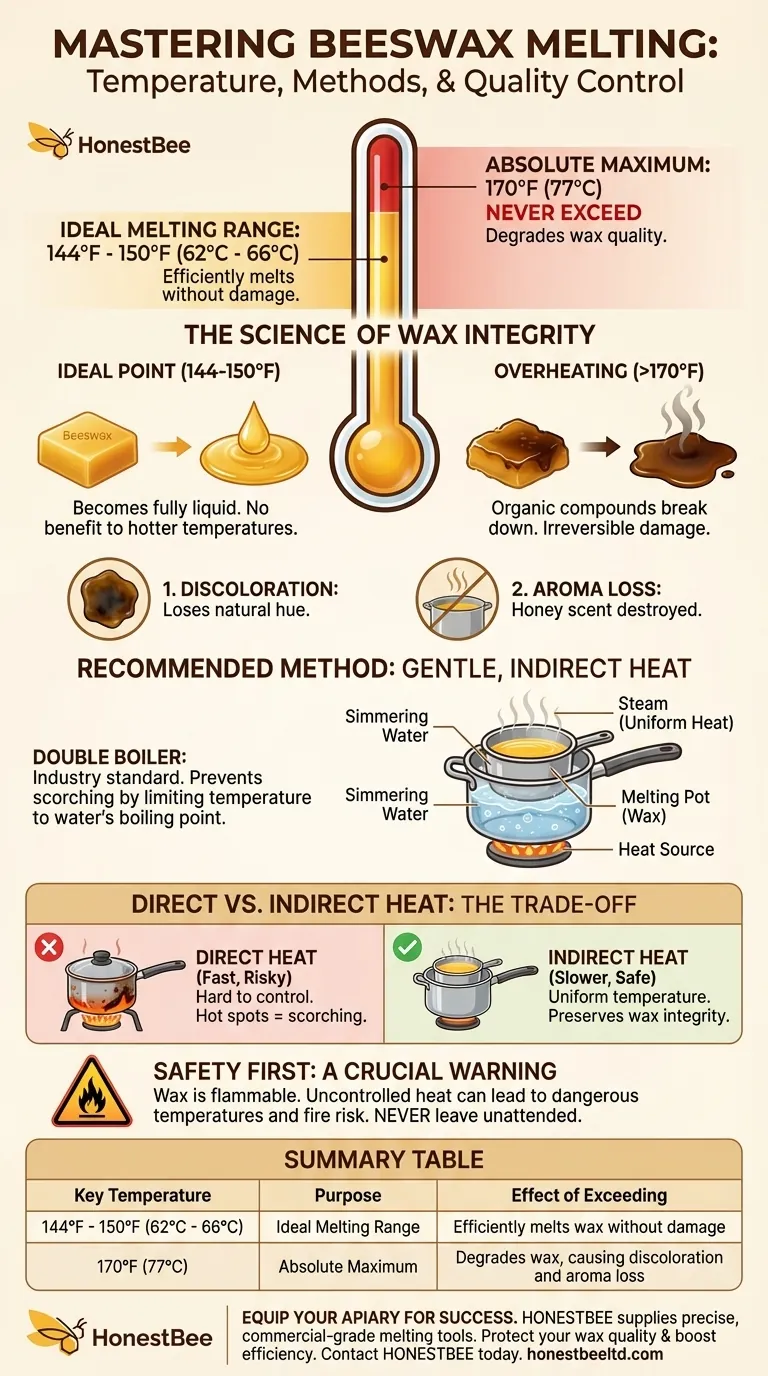

To melt beeswax properly, you should aim for a temperature between 144°F and 150°F (62°C to 66°C). This is the ideal range where the wax will melt efficiently. Critically, the wax temperature should never exceed 170°F (77°C), as this will degrade its quality.

The core principle is not simply to melt the wax, but to do so with gentle, indirect heat. Controlling the temperature is essential for preserving the wax's natural properties and ensuring a safe process.

The Science of Melting Beeswax

Understanding the "why" behind these temperature guidelines is key to achieving consistent, high-quality results. Beeswax is a natural material that responds predictably to heat, but it can be easily damaged if that heat is not controlled.

The Ideal Melting Point

The transition from solid to liquid for beeswax occurs right around 144°F to 150°F (62°C to 66°C). Bringing the wax into this range is all that is required for it to become fully liquid and ready for use in candles, balms, or other projects.

There is no benefit to making it hotter; you only introduce risk.

Why the Maximum Temperature Matters

Exceeding 170°F (77°C) is the most common mistake and the primary cause of poor results. At these higher temperatures, the delicate organic compounds in the beeswax begin to break down.

This degradation results in two undesirable outcomes:

- Discoloration: The wax will darken, losing its natural golden or white hue.

- Aroma Loss: The subtle, pleasant honey scent of the beeswax will be permanently destroyed.

Recommended Melting Methods

The goal is to apply gentle, indirect heat. Placing a pot of wax directly on a heat source makes it nearly impossible to regulate the temperature, leading to scorching and overheating.

The Double Boiler Method

Using a double boiler is the industry standard for a reason. This setup involves two pots: a larger one filled with a few inches of simmering water and a smaller one (the melting pot) that sits inside it.

The steam and hot water from the bottom pot gently and evenly heat the wax in the top pot, making it impossible for the wax to get significantly hotter than the boiling point of water (212°F or 100°C), providing a crucial safety buffer.

The DIY Double Boiler

If you don't own a double boiler, you can easily create one. Place a heat-safe glass or metal container (like a glass measuring cup or a dedicated pouring pot) inside a larger saucepan.

Add water to the saucepan, ensuring the water level is high enough to heat the sides of the inner container but not so high that it will splash into your wax.

Understanding the Trade-offs and Risks

Choosing your heating method involves a direct trade-off between speed and quality. While direct heat might seem faster, the risks almost always outweigh the benefits.

Direct Heat vs. Indirect Heat

Direct heat (e.g., a pot directly on an electric or gas stove) is fast but incredibly difficult to control. It creates hot spots on the bottom of the pot that will quickly overheat and scorch the wax long before the entire volume has melted.

Indirect heat (the double boiler method) is slower but provides the gentle, uniform temperature needed to preserve the wax's integrity.

The Risk of Overheating and Fire

Beyond damaging the wax's color and aroma, excessive heat poses a significant safety risk. Wax is a flammable substance. While 170°F is well below its flash point, an uncontrolled heating method can quickly lead to dangerous temperatures.

For this reason, you must never leave melting wax unattended, especially near an open flame.

Making the Right Choice for Your Project

Your goal dictates your method. By respecting the temperature limits, you ensure a predictable and successful outcome.

- If your primary focus is preserving the natural color and aroma: Use a double boiler and a thermometer to ensure the wax never exceeds 170°F and spends most of its time in the 144-150°F range.

- If your primary focus is safety and consistency: The double boiler method is non-negotiable. It provides the most reliable and safest way to melt beeswax without the risk of scorching or a dangerous temperature spike.

By managing the temperature with care, you gain complete control over the quality and safety of your final product.

Summary Table:

| Key Temperature | Purpose | Effect of Exceeding |

|---|---|---|

| 144°F - 150°F (62°C - 66°C) | Ideal Melting Range | Efficiently melts wax without damage |

| 170°F (77°C) | Absolute Maximum | Degrades wax, causing discoloration and aroma loss |

Ready to master your beeswax processing? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the precise, reliable tools needed for temperature-controlled melting. From high-quality melting tanks to accurate thermometers, our wholesale-focused operations ensure you get professional-grade equipment that protects your wax's integrity and boosts your operation's efficiency. Contact HONESTBEE today to equip your business for superior results.

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

People Also Ask

- How can you monitor the temperature of beeswax as it melts? Ensure Quality & Safety with Precise Control

- What are wax melters used for? Unlock Efficient Wax Processing for Your Business

- What are the safety precautions when working with melted beeswax? Prevent Burns and Fire Hazards

- What are the steps for using a wax melter to melt beeswax? Master Safe, Efficient Beeswax Processing

- What temperature range is considered gentle heat for melting beeswax? Preserve Aroma & Color