The Psychology of a Simple Choice

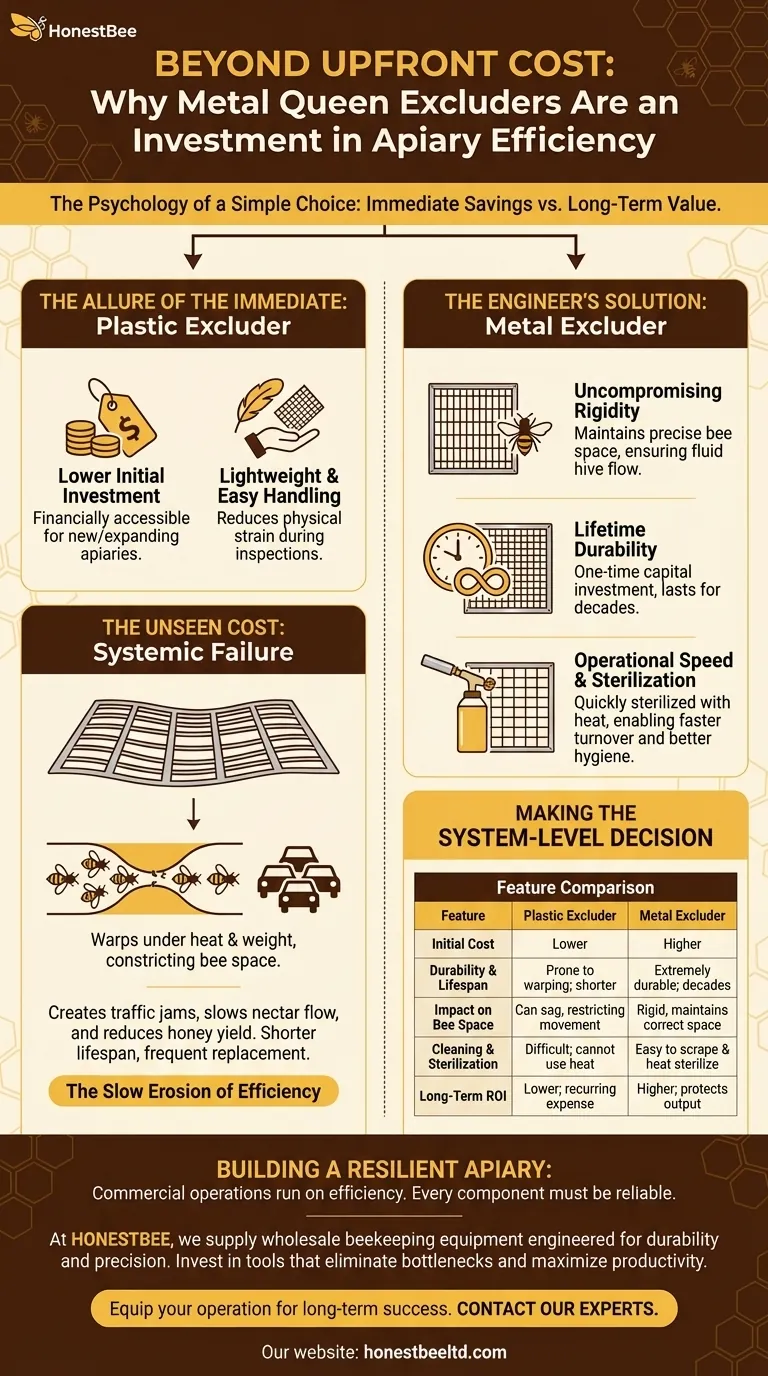

In beekeeping, as in life, we face constant trade-offs between the immediate and the enduring. Consider the queen excluder. The choice seems simple: a lightweight, inexpensive plastic grid versus a heavier, costlier metal one.

This decision engages a powerful psychological bias—our preference for immediate savings over long-term value. We see the upfront cost of metal as a loss, and the low price of plastic as a win.

But the queen excluder isn't just a piece of hardware. It is the gatekeeper to your honey supers, a critical control point in the logistics of your entire operation. A failure here doesn't just affect one component; it creates a bottleneck that compromises the whole system.

The Allure of the Immediate: The Case for Plastic

The appeal of plastic excluders is undeniable, and for some, it's a perfectly logical starting point.

Lower Initial Investment

For a new apiary or one expanding rapidly, budget is a primary constraint. Plastic allows a beekeeper to equip numerous hives for a fraction of the cost of metal, making it a financially accessible option.

Lightweight and Easy Handling

During inspections, every ounce matters. Plastic is light, reducing the physical strain of lifting heavy honey supers, especially when managing dozens or hundreds of colonies.

The Unseen Cost: When Plastic Fails Systemically

The true cost of a tool is not its purchase price, but the price of its failure. The primary failure of plastic is subtle but devastating: it warps.

Imagine a hot summer afternoon. Inside the hive, temperatures rise. The plastic excluder, under the weight of thousands of bees, begins to sag. The carefully engineered "bee space" between the excluder and the top bars of the frames below shrinks.

The Slow Erosion of Efficiency

This sagging creates a traffic jam. Worker bees, laden with nectar, struggle to pass through the constricted gateway. Foraging trips take longer. The flow of resources into the honey supers slows to a trickle.

The problem compounds. Congestion in the brood chamber can lead to management issues, while the reduced honey yield directly impacts your revenue. The plastic excluder, chosen for its low cost, begins to impose a hidden tax on your productivity. Add to this its shorter lifespan and tendency to become brittle, and it becomes a recurring expense, not a one-time purchase.

An Engineer's Solution: The Case for Inflexible Metal

Metal is the engineer's answer to the problem of warping. It is a material defined by its rigidity and permanence—a tool built to execute its single purpose flawlessly, for decades.

Uncompromising Rigidity: Protecting Bee Space

A metal excluder does not sag. It sits perfectly flat, maintaining the precise bee space essential for a fluid, efficient hive. It is a passive tool that actively protects the logistical flow of your colony, ensuring your workforce can operate at peak capacity.

Lifetime Durability: A One-Time Investment

A well-maintained metal excluder can outlast the beekeeper. While the upfront cost is higher, its lifespan transforms it from an expense into a capital investment. When amortized over decades of service, its cost per year plummets, making it the far more economical choice for any serious operation.

Operational Speed: The Advantage of Heat Sterilization

For a commercial apiary, time is money. Metal excluders can be scraped clean of wax and propolis, then sterilized instantly with a blowtorch. This rapid, effective method is impossible with plastic. It allows for faster equipment turnover and superior hygiene, reducing the risk of disease transmission between hives.

Making the System-Level Decision

The choice is not merely between two materials. It is between two operational philosophies.

One prioritizes minimizing upfront capital, accepting the hidden costs of lower efficiency and future replacements. The other prioritizes long-term system reliability, investing in tools that eliminate bottlenecks and maximize productivity over the long run.

For a commercial operation, where efficiency is paramount, the choice becomes clear.

| Feature | Plastic Excluder | Metal Excluder |

|---|---|---|

| Initial Cost | Lower | Higher |

| Durability & Lifespan | Prone to warping/sagging; shorter lifespan | Extremely durable; lasts for decades |

| Impact on Bee Space | Can sag, restricting worker bee movement | Rigid, maintains correct bee space |

| Cleaning & Sterilization | Difficult to clean thoroughly; cannot use heat | Easy to scrape and sterilize with a blowtorch |

| Long-Term ROI | Lower; requires replacement and impacts yield | Higher; a one-time purchase that protects output |

Building a Resilient Apiary

Commercial apiaries run on efficiency. Every piece of equipment must be a reliable component in a system designed for maximum honey production. You cannot afford the recurring, hidden costs of tools that fail under pressure.

At HONESTBEE, we supply wholesale beekeeping equipment built for the rigors of commercial use. Our metal queen excluders are engineered for durability and precision because we understand that your success depends on the reliability of your tools. By ensuring unimpeded access to honey supers, they become a silent partner in the profitability of your apiary.

Equip your operation for long-term success. Contact Our Experts

Visual Guide

Related Products

- Metal Queen Bee Excluder for Beekeeping

- Premium Wood Framed Metal Wire Queen Bee Excluder

- Wooden Queen Bee Excluder for Beekeeping

- Professional Plastic Queen Excluder for Modern Beekeeping

- High Performance Plastic Queen Excluder for Beekeeping and Apiary Management

Related Articles

- The Ten-Year Gate: Why Your Queen Excluder Defines Your Apiary's Economics

- The Geometry of Order: Why the Queen Excluder is a Beekeeper's Most Strategic Tool

- How to Optimize Queen Excluder Placement for Healthier Hives and Higher Honey Yields

- Beyond the Gate: The Queen Excluder as a Keystone of Apiary Efficiency

- Queen Excluders: Strategic Tool or Barrier to Natural Beekeeping?