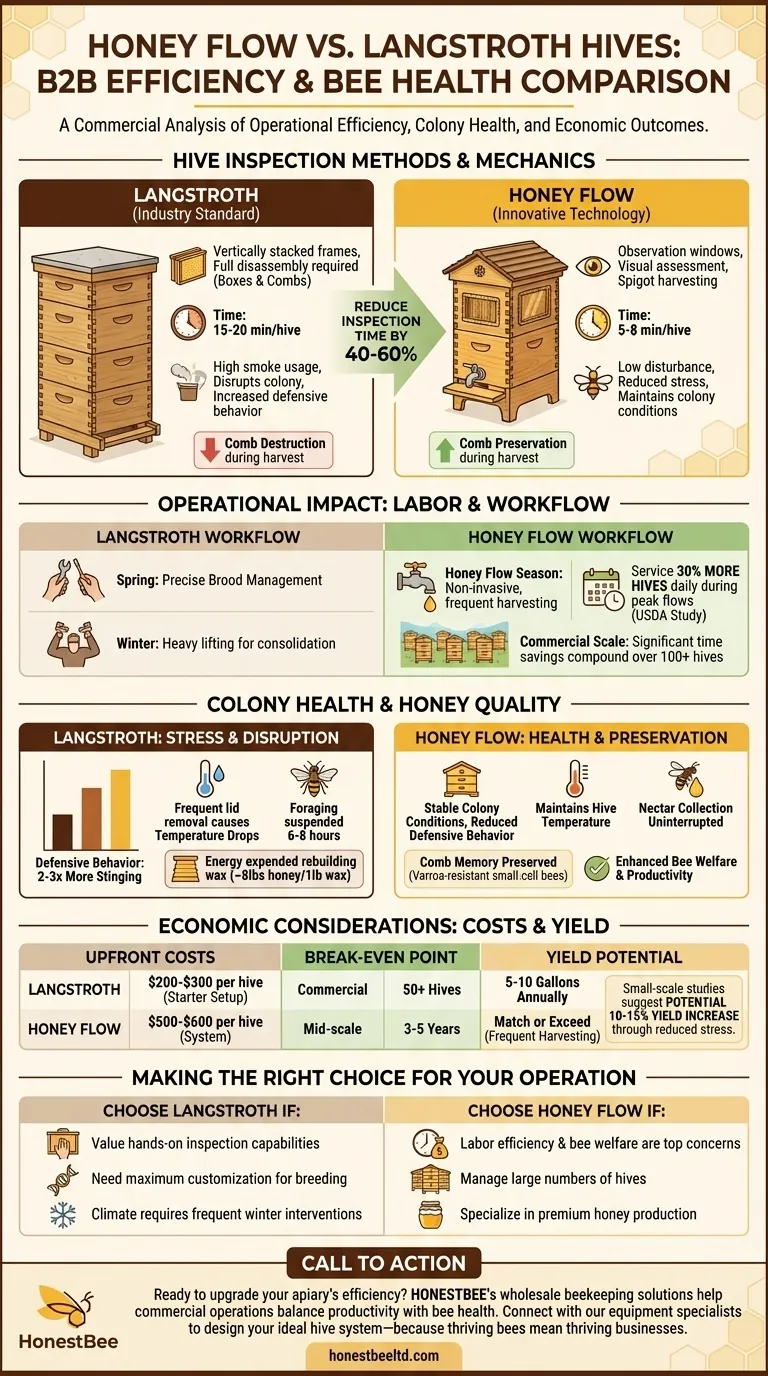

Beekeepers face a critical choice when selecting hive systems: Does the convenience of Honey Flow's innovative technology justify its higher costs compared to traditional Langstroth setups? This analysis compares operational efficiency, colony health, and economic outcomes to help commercial apiaries and distributors make informed decisions.

Hive Inspection Methods Compared

Langstroth System Mechanics and Limitations

The century-old Langstroth design remains the industry standard for good reason. Its vertically stacked frames allow beekeepers to inspect individual combs systematically—a crucial advantage for monitoring brood patterns and disease. However, this strength becomes a liability during honey harvests. Each inspection requires:

- Full disassembly of hive boxes

- Physical comb removal

- Significant smoke usage to calm bees

Research shows these disruptions trigger measurable stress responses in colonies, including increased defensive behavior and temporary drops in honey production.

Honey Flow's Window Technology in Action

The patented Honey Flow system addresses these pain points through observation windows and a unique honey extraction mechanism. Beekeepers can:

- Assess colony strength visually without dismantling the hive

- Harvest honey via spigot without comb destruction

- Reduce inspection time by approximately 40-60% compared to Langstroth

This innovation proves particularly valuable during peak nectar flows when frequent monitoring is essential but time-consuming.

Operational Impact on Beekeepers

Labor Intensity and Time Requirements

Commercial operations managing 100+ hives report stark differences:

- Langstroth: Requires 15-20 minutes per hive for thorough inspection

- Honey Flow: Cuts inspection time to 5-8 minutes through window checks

The time savings compound significantly across large apiaries. One USDA study found beekeepers could service 30% more hives daily using flow systems during critical pollination contracts.

Seasonal Workflow Adaptations

Both systems demand different seasonal approaches:

- Spring buildup: Langstroth allows more precise brood management

- Honey flow season: Honey Flow's non-invasive harvesting prevents nectar flow disruptions

- Winter prep: Langstroth requires heavier lifting for box consolidation

Honey Flow's design shines during high-frequency harvest periods but offers fewer customization options for overwintering strategies.

Colony Health and Honey Quality

Stress Indicators in Frequently Disturbed Hives

Comparative studies reveal:

- Defensive behavior: Langstroth inspections provoke 2-3x more stinging incidents

- Brood temperature fluctuations: Frequent lid removal causes measurable hive temperature drops

- Foraging disruption: Traditional harvests can suspend nectar collection for 6-8 hours

Honey Flow's reduced disturbance maintains more stable colony conditions, though some beekeepers argue the lack of hands-on inspection risks missing early signs of disease.

Comb Preservation During Inspections

The Langstroth system's comb destruction during harvests forces bees to:

- Expend energy rebuilding wax (consuming ~8 lbs of honey per 1 lb of wax)

- Potentially rebuild contaminated comb if diseases are present

Honey Flow's preservation of drawn comb provides measurable advantages:

- Maintains the colony's "memory" of cell size for varroa-resistant small-cell bees

- Reduces energy expenditure between flows

Economic Considerations

Upfront Costs vs Long-Term Efficiency Gains

Price comparisons show:

- Langstroth starter setup: $200-300 per hive

- Honey Flow system: $500-600 per hive

The break-even point typically occurs at:

- 50+ hives for commercial pollination operations

- 3-5 years for mid-scale honey producers

Yield Comparisons Across Hive Types

While Langstroth hives traditionally yield 5-10 gallons annually, Honey Flow systems can match or exceed this when:

- Nectar flows are consistent

- Colonies have strong overwinter survival rates

- Beekeepers harvest more frequently (enabled by the easier process)

Small-scale studies suggest Honey Flow may increase total yield by 10-15% through reduced disruption stress, though commercial-scale data remains limited.

Making the Right Choice for Your Operation

The optimal system depends on your operational priorities:

- Choose Langstroth if: You value hands-on inspection capabilities, need maximum customization for breeding programs, or operate in climates requiring frequent winter interventions.

- Choose Honey Flow if: Labor efficiency and bee welfare are top concerns, you manage large numbers of hives, or you specialize in premium honey production.

For commercial beekeepers, the decision often comes down to scale. Those managing hundreds of hives typically find the labor savings justify Honey Flow's premium, while smaller operations may prefer Langstroth's versatility.

Ready to upgrade your apiary's efficiency? HONESTBEE's wholesale beekeeping solutions help commercial operations balance productivity with bee health. Connect with our equipment specialists to design your ideal hive system—because thriving bees mean thriving businesses.

Visual Guide

Related Products

- Langstroth Bee Hives Bee Keeping Box for Beginners Beekeeping

- Automatic Honey Flow Beehive 4 Frame Mini Hive for Beekeeping

- Professional Hive Top Bee Feeder for Beekeeping

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- Commercial 48-Frame Stainless Steel Honey Extractor

Related Articles

- How to Choose Between Top Bar and Langstroth Hives for Effortless Beekeeping

- How Medium Boxes Elevate Beekeeping Efficiency: Ergonomics, Hive Health & Cost Savings

- How Medium Boxes Make Beekeeping Easier While Protecting Your Hives

- The Essential Guide to Beehive Boxes: Maximizing Colony Health and Productivity

- The Beekeeper's Nightmare: Why Moving Your Hives Can End in Disaster—And the Design That Prevents It