For beekeepers and small-scale producers, controlling honey moisture isn’t just about quality—it’s a regulatory necessity. Excess moisture risks fermentation, spoilage, and non-compliance with food safety standards. This guide delivers actionable, research-supported methods to optimize moisture reduction while preserving flavor, texture, and marketability.

Understanding Honey Moisture Fundamentals

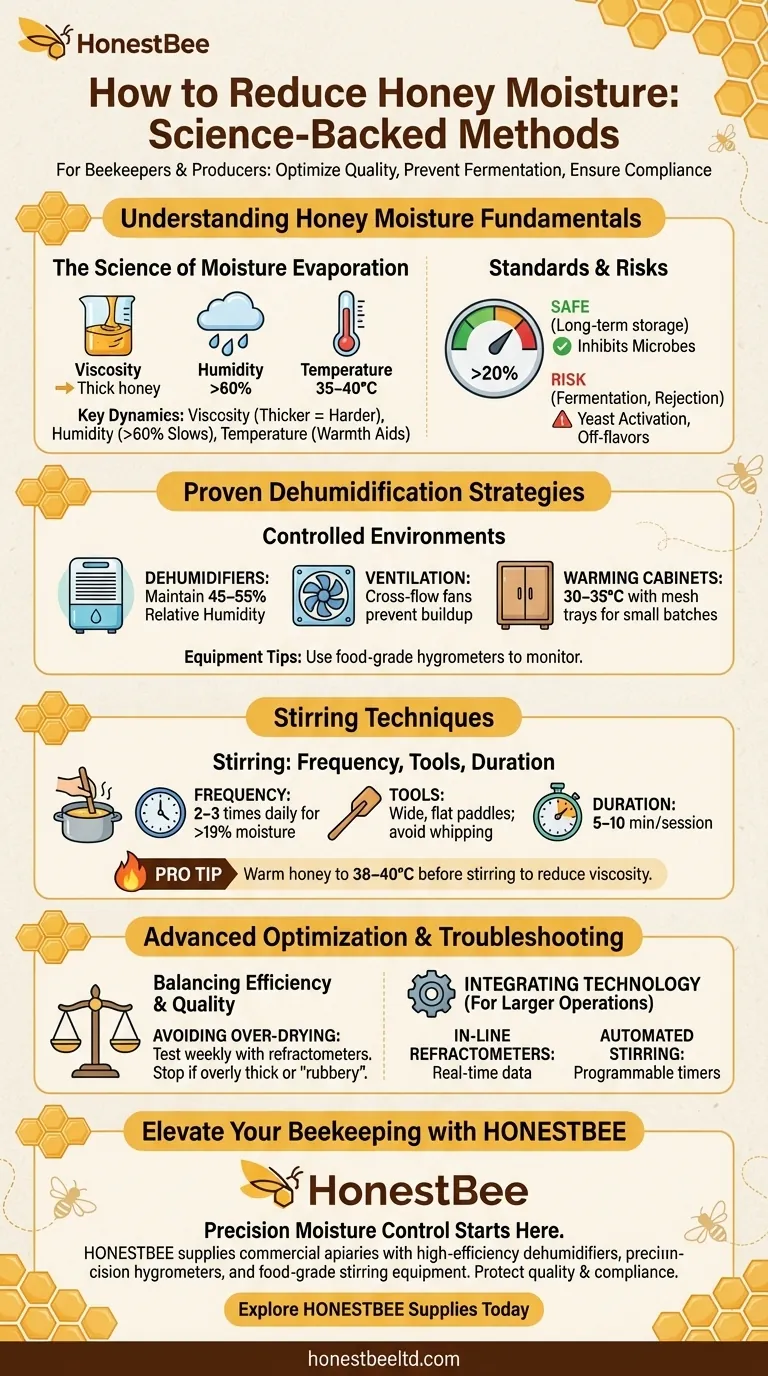

The Science of Moisture Evaporation in Honey

Honey’s moisture content hinges on environmental factors and beekeeping practices. Nectar’s natural water concentration (often 60–80%) is reduced by bees through fanning and enzymatic activity, but post-harvest handling determines final moisture levels.

Key dynamics:

- Viscosity: Thicker honey (cooler or high-sugar) resists moisture release, requiring adjusted processing.

- Humidity: Ambient humidity above 60% slows evaporation, while arid conditions accelerate it—sometimes unevenly.

- Temperature: Warmth (ideally 35–40°C) lowers viscosity, aiding moisture migration without degrading enzymes.

Industry Standards: Safe Moisture Thresholds and Risks

Regulatory bodies like the USDA and Codex Alimentarius set thresholds:

- ≤18.6% moisture: Safe for long-term storage; inhibits microbial growth.

- >20% moisture: High fermentation risk; may be rejected by buyers.

Risks of improper control:

- Fermentation: Yeast activation creates off-flavors and gas.

- Crystallization: Variable moisture speeds or disrupts crystallization patterns.

Proven Dehumidification Strategies

Controlled Environments: Humidity Settings and Equipment Selection

Ideal drying conditions balance airflow, warmth, and humidity:

- Dehumidifiers: Maintain 45–55% relative humidity in drying rooms.

- Ventilation: Cross-flow fans prevent localized humidity buildup.

- Low-tech solutions: Silica gel packs in storage bins absorb residual moisture.

Equipment tips:

- Use food-grade hygrometers to monitor room humidity.

- For small batches, warming cabinets (30–35°C) with mesh trays boost evaporation.

Stirring Techniques: Frequency, Tools, and Duration

Manual or mechanical stirring counteracts viscosity barriers:

- Frequency: Stir 2–3 times daily for high-moisture (>19%) honey.

- Tools: Wide, flat paddles distribute heat evenly; avoid whipping (introduces air).

- Duration: 5–10 minutes per session, depending on batch size.

Pro Tip: Warm honey to 38–40°C before stirring to reduce viscosity.

Advanced Optimization and Troubleshooting

Balancing Efficiency and Quality: Avoiding Over-Dehumidification

Over-drying

- Checkpoints: Test moisture weekly with refractometers.

- Stop signs: Honey becomes overly thick or develops a "rubbery" surface.

Integrating Technology: Sensors and Automation

For larger operations:

- In-line refractometers: Provide real-time moisture data during extraction.

- Automated stirring systems: Programmable timers maintain consistency.

Elevate Your Beekeeping with HONESTBEE

Precision moisture control starts with the right tools. HONESTBEE supplies commercial apiaries and distributors with high-efficiency dehumidifiers, precision hygrometers, and food-grade stirring equipment—wholesale solutions designed to protect your honey's quality and compliance.

Ready to optimize your harvest? Explore HONESTBEE's beekeeping supplies today.

Visual Guide

Related Products

- Precision Honey Refractometer Instrument for Quality Assessment

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- Inverted Squeezable Honey Jar with No Drip Flip Top Cap for Easy Pouring

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

Related Articles

- The Second Half of the Measurement: Protecting the Integrity of Your Honey Refractometer

- How Beekeepers Prevent Honey Spoilage Through Precision Moisture Control

- How to Perfect Honey Moisture Levels: A Beekeeper’s Guide to Refractometer Mastery

- The Unseen Architecture of Trust: Calibrating the Honey Refractometer

- How to Accurately Test Honey Readiness: Science-Backed Methods for Beekeepers