It’s a scenario every commercial beekeeper dreads. A yard that was thriving just weeks ago now has several weak hives. You check for mites, you evaluate the queen, you puzzle over weather patterns, but you can’t find a definitive culprit. The losses are frustrating, costly, and worst of all, unexplained. You might be looking for a complex disease, but the source of the problem could be something you hold in your hand every single day.

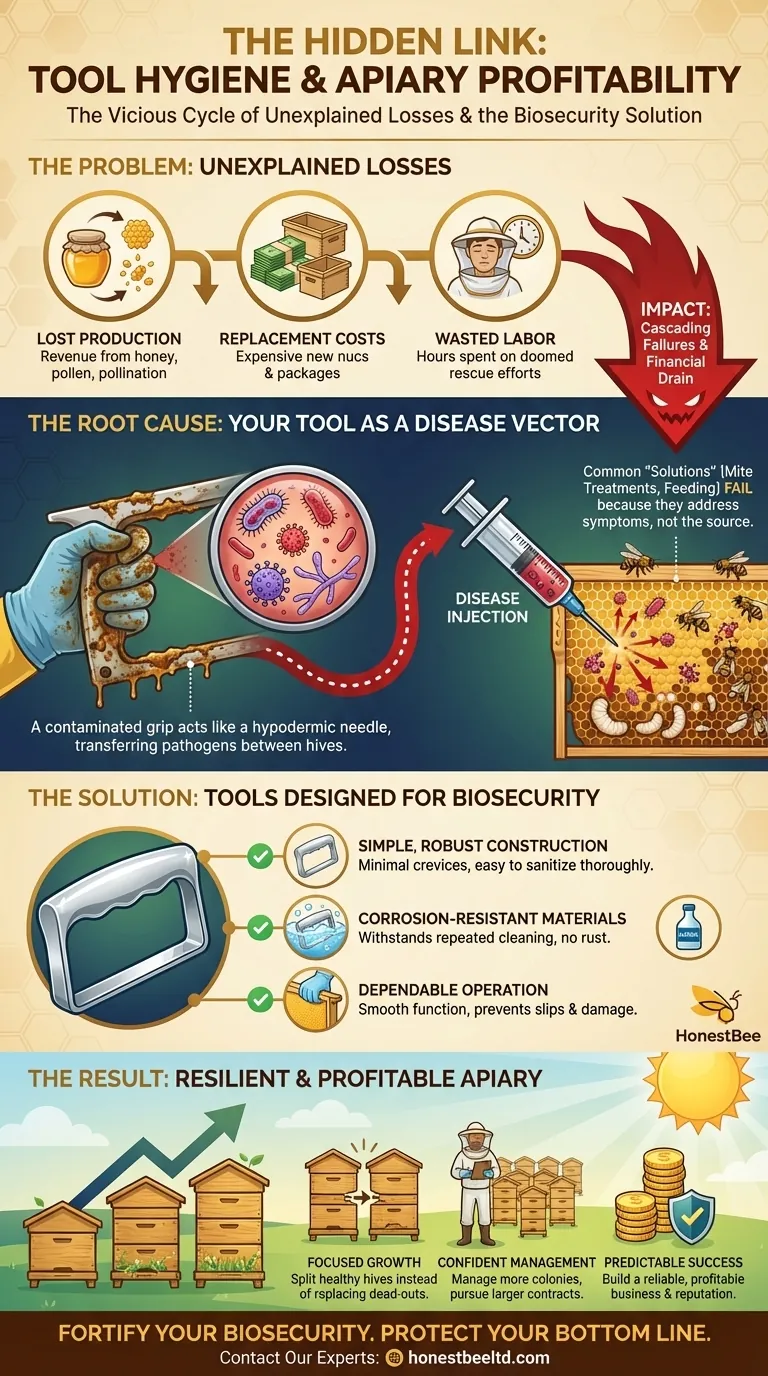

The Vicious Cycle of Unexplained Losses

When a hive weakens, the standard playbook kicks in: mite treatments, supplemental feeding, maybe requeening. Beekeepers invest significant time and money treating these symptoms. Yet, sometimes, the problem persists or spreads inexplicably to adjacent hives. The operation gets caught in a reactive, expensive cycle of trying to save colonies without ever addressing the root cause.

This isn't just about losing a few bees; it's a direct hit to your bottom line. Each lost colony represents:

- Lost Production: Vanished revenue from honey, pollen, or pollination contracts.

- Replacement Costs: The significant expense of purchasing nucs or packages to rebuild your numbers.

- Wasted Labor: Hours spent on "rescue" efforts that were doomed to fail.

- Reputation Damage: For distributors, selling equipment that contributes to customer failure is a business risk. For apiaries, unreliable colony strength can jeopardize valuable pollination agreements.

The "good enough" approach of a quick wipe-down on a tool seems efficient in the moment, but it’s a false economy that paves the way for these cascading failures.

The Root of the Problem: Your Tool as a Disease Vector

The sticky, resinous substance you scrape off your tools isn't just a nuisance; it's a perfect vehicle for pathogens. Propolis and wax residue can harbor a microscopic army of bacteria, viruses, and spores, including the incredibly resilient spores of American Foulbrood (AFB).

Here’s the critical insight many overlook: A contaminated frame grip acts as a hypodermic needle, injecting disease directly from one colony into the next.

You could have the best mite management in the country, but if you inspect a subtly-infected hive and then move to a healthy one without sterilizing your grip, you are personally ensuring the pathogen’s spread. This is why the common "solutions" fail. They are treating the smoke while ignoring the fire. Treating a hive for mites won't cure it of a bacterial infection you just introduced. The true problem isn't the hive's susceptibility; it's the continuous re-introduction of pathogens from a contaminated tool.

The Solution Embodied: Tools Designed for Biosecurity

To break this cycle, you need to shift from simply "cleaning" to practicing rigorous biosecurity. This requires a protocol and, just as importantly, tools that are built to facilitate it. A professional tool is not just strong—it is designed to be easily and effectively sanitized.

This is the principle behind HONESTBEE's professional-grade equipment. Our tools are designed for the realities of commercial beekeeping, where efficiency and biosecurity are paramount.

- Simple, Robust Construction: Our frame grips are built with minimal complex joints or crevices where propolis and pathogens can hide, making them faster and easier to clean thoroughly.

- Corrosion-Resistant Materials: They are engineered to withstand the repeated use of propolis solvents like rubbing alcohol and soap-and-water washing without rusting or seizing, ensuring a long and reliable service life.

- Dependable Operation: A clean, well-maintained grip functions smoothly, preventing sudden slips that can kill bees, damage comb, and compromise your inspection.

Our equipment is not just a tool; it is an integral part of a professional biosecurity system designed to protect your investment.

Beyond the Fix: Building a More Resilient Apiary

When you stop playing defense against unexplained losses, you can focus on growth. Integrating a strict tool-hygiene protocol, supported by the right equipment, transforms your entire operation.

Instead of constantly replacing dead-outs, you can focus on splitting healthy hives. Instead of worrying about disease outbreaks, you can confidently manage more colonies and pursue larger contracts. You move from a state of uncertainty to one of control, building a more predictable, profitable, and resilient business. For distributors, this means empowering your clients with the tools and knowledge to succeed, cementing your status as a trusted partner in their growth.

Your tools should be an asset, not a liability. Shifting your perspective on tool maintenance from a minor chore to a cornerstone of your risk management strategy is one of the most powerful changes you can make. Let us provide you with the equipment designed to support that professional standard.

Ready to equip your operation for success and leave behind the constant worry of disease transmission? Our team specializes in supplying commercial apiaries and distributors with the durable, reliable tools needed to maintain a healthy and productive business. Contact Our Experts to discuss how the right equipment can fortify your biosecurity protocols and protect your bottom line.

Visual Guide

Related Products

- Premium Frame Grip with Ergonomic Wood Handles

- HONESTBEE Classic Pry Bar Hive Tool with High Visibility Finish for Beekeeping

- Professional Drop-Style Hive Handles for Beekeeping

- Ergonomic Two Person Foldable Hive Lifter

- Heavy-Duty Stainless Steel Frame Perch

Related Articles

- The Beekeeper's Scalpel: How a Simple Hive Tool Dictates Colony Health

- Calm Hands in the Colony: The Ergonomic Argument for Frame Grips

- The Gentle Art of Leverage: Why Your Hive Tool Isn't a Crowbar

- Beyond the Hammer: The Psychological Calculus of a Bee Frame Machine

- The Physics of Calm: How a Simple Hive Tool Dictates the Success of an Apiary