No, you are not required to heat honey before bottling it. If the honey is fresh from the extractor and still warm from the hive, it can often be bottled directly. However, heating is a very common practice in both artisanal and commercial operations for practical reasons related to flow, filtration, and shelf stability.

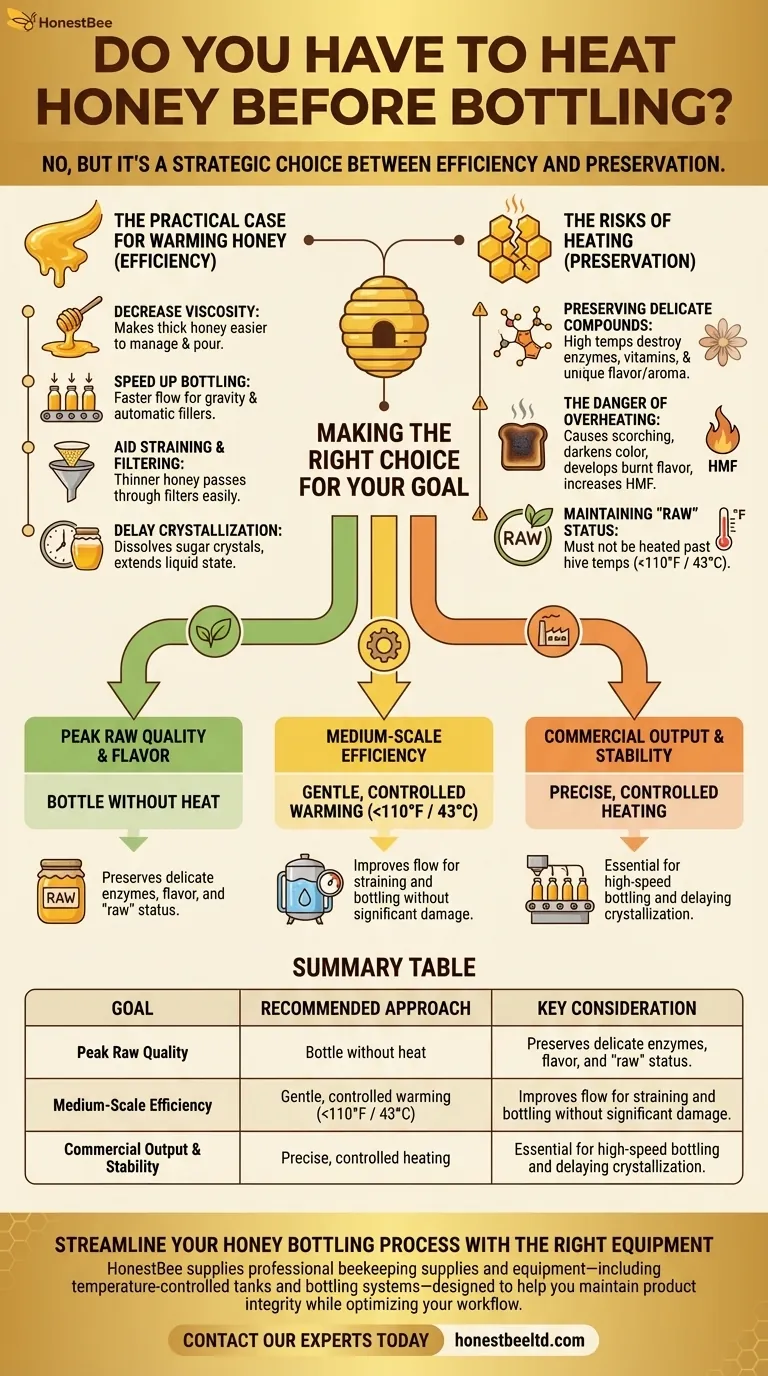

The decision to heat honey is not about safety, but a strategic choice between operational efficiency and the preservation of the honey's most delicate natural qualities. Gentle warming makes bottling easier, but excessive heat can degrade the very characteristics that make honey unique.

The Practical Case for Warming Honey

Producers often warm honey to solve logistical challenges inherent in handling a thick, viscous liquid. The primary goal is to make the honey easier to manage from the holding tank to the final bottle.

To Decrease Viscosity

Honey's thickness, or viscosity, can make it slow and difficult to pour. Gently warming it reduces this viscosity, allowing it to flow much more freely and consistently.

To Speed Up Bottling

A lower viscosity directly translates to a faster bottling process. Honey that flows easily moves more quickly through pumps, pipes, and bottling machine nozzles, increasing overall efficiency. This is critical for both simple gravity bottlers and high-speed automatic filling machines.

To Aid Straining and Filtering

Most honey is strained to remove small particles of beeswax, pollen, and other hive debris. Warmed, thinner honey passes through filters much more easily than cool, thick honey, resulting in a clearer final product with less effort.

To Delay Crystallization

Heating dissolves the tiny sugar crystals that are naturally present in honey. By doing so, it significantly delays the onset of crystallization, keeping the honey in a liquid state on the shelf for a longer period.

Understanding the Trade-offs: The Risks of Heating

While warming honey offers practical benefits, it must be done with extreme care. The very properties that define high-quality, raw honey are sensitive to heat.

Preserving Delicate Compounds

Honey contains natural enzymes, vitamins, and volatile aromatic compounds that create its unique flavor and aroma profile. High temperatures can destroy these delicate elements, fundamentally altering the character of the honey.

The Danger of Overheating

Applying too much heat can scorch the honey, causing it to darken in color and develop a caramelized or burnt flavor. It also increases the levels of Hydroxymethylfurfural (HMF), a compound that is used as an indicator of heat and storage damage.

Maintaining "Raw" Status

For honey to be marketed as "raw," it must not be heated past the temperatures naturally found in the hive (typically under 110°F or 43°C). Bottling without any heat is the surest way to preserve this valuable designation.

Making the Right Choice for Your Goal

Your approach should be dictated by your scale, your equipment, and the type of product you want to sell.

- If your primary focus is peak "raw" quality and flavor: Bottle your honey without heat, especially for smaller batches that can be handled manually.

- If your primary focus is efficiency for a medium-scale operation: Use a controlled, low-temperature warming method (like a water-jacketed tank) to improve flow without damaging the honey's core properties.

- If your primary focus is commercial output and long-term shelf stability: A precise and controlled heating process is often a necessary step to ensure product consistency and efficiency in automated systems.

Ultimately, your bottling method should be a deliberate choice that protects the integrity of the product you aim to deliver.

Summary Table:

| Goal | Recommended Approach | Key Consideration |

|---|---|---|

| Peak Raw Quality | Bottle without heat | Preserves delicate enzymes, flavor, and "raw" status. |

| Medium-Scale Efficiency | Gentle, controlled warming (<110°F / 43°C) | Improves flow for straining and bottling without significant damage. |

| Commercial Output & Stability | Precise, controlled heating | Essential for high-speed bottling and delaying crystallization. |

Streamline Your Honey Bottling Process with the Right Equipment

Whether your commercial apiary or distribution business prioritizes the pristine quality of raw honey or the high-speed efficiency of large-scale bottling, having the right equipment is crucial. HONESTBEE supplies professional beekeeping supplies and equipment—including temperature-controlled tanks and bottling systems—designed to help you maintain product integrity while optimizing your workflow.

Contact our experts today to discuss wholesale solutions tailored to your specific bottling goals.

Visual Guide

Related Products

- Silicone Rubber Honey Drum Heating Belt

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

People Also Ask

- What are the features of the adjustable thermostat on a honey heating blanket? Precision Control for Professional Beekeeping

- What sizes are honey heating blankets available in? Find the Perfect Fit for Your Pails and Drums

- Are there specialized designs of honey heating blankets for easier dispensing? Optimize Your Bottling Workflow

- How does specialized industrial honey equipment maintain quality? Preserve Premium Flavor and Purity

- What are the steps involved in the conventional thermal processing of honey? Optimize Your Honey Quality