To use a steam wax melter, you fill a separate generator with water, place your old frames into the melter's main body, and apply heat. As the water boils, steam is piped into the melter, where its consistent, high temperature gently melts the wax, which then drains through a filter and out a tap for collection.

The core principle is not just melting wax, but using the indirect, moist heat of steam to efficiently render a higher quality, unburnt wax while simultaneously sterilizing the wooden frames with minimal manual intervention.

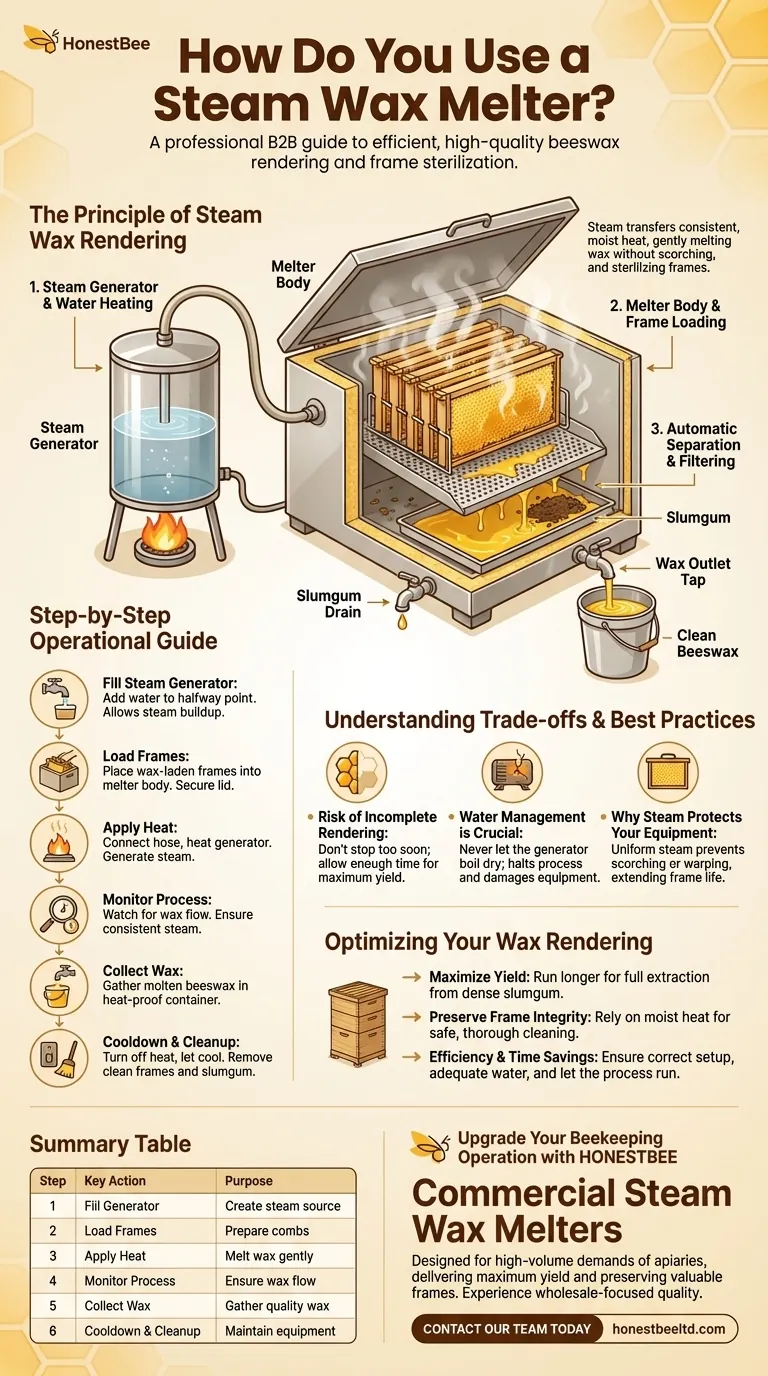

The Principle of Steam Wax Rendering

A steam wax melter operates on a simple but highly effective two-chamber system. Understanding this principle helps you use the equipment more effectively and appreciate its advantages over other methods.

How Steam Transfers Heat

Steam provides a consistent, pervasive heat source. The temperature of the steam is high enough to melt wax (which melts above 70°C) but is naturally regulated, preventing the scorching and darkening that often occurs with direct-heat methods.

This gentle, moist heat penetrates the entire honeycomb structure, releasing wax efficiently from old cocoons and propolis.

The Two-Chamber System

Your melter consists of two main parts. First is the steam generator, a sealed container where water is boiled. Second is the melter body, an insulated box where you place the frames.

A hose connects the two, directing the pressurized steam from the generator into the melter, ensuring all frames are enveloped in hot steam.

Automatic Separation and Filtering

As the wax liquefies, it drips down to a slanted collection pallet at the bottom of the melter. This process separates the liquid wax from the "slumgum"—the collection of old cocoons, pollen, and debris left behind.

The liquid wax then passes through a filter mesh before exiting through a drain tap, giving you a cleaner initial product.

Step-by-Step Operational Guide

Following the correct procedure ensures you get the highest yield and purest wax without damaging your equipment.

Step 1: Prepare the Steam Generator

Fill the steam generator with water to approximately the halfway point. This leaves sufficient space for steam to accumulate and build pressure.

Step 2: Load the Frames

Open the main melter body and place the frames you wish to render into the internal basket or rack. Close and secure the lid to ensure a good seal.

Step 3: Apply Heat and Generate Steam

Connect the hose from the steam generator to the melter body's inlet port. Begin heating the water in the generator using its designated heat source, whether it's an external fire or a built-in electric element.

Step 4: Monitor the Melting Process

Once the water boils, steam will flow into the melter. Within minutes, you should see liquid wax begin to flow from the outlet tap. The process is largely self-sustaining.

Step 5: Collect the Rendered Wax

Place a clean, heat-proof container under the tap to collect the molten beeswax. Let the process continue until the wax flow slows to a drip, indicating most of the wax has been rendered.

Step 6: Cooldown and Cleanup

Once finished, turn off the heat source and allow the system to cool completely. Carefully open the melter to remove the now-clean frames and discard the remaining slumgum.

Understanding the Trade-offs and Best Practices

While steam melters are highly efficient, knowing their operational nuances is key to achieving optimal results and avoiding common pitfalls.

Risk of Incomplete Rendering

If you stop the process too soon, a significant amount of wax can remain trapped in the slumgum. It is better to let the steam run slightly longer to ensure you have maximized your yield from the frames.

Water Management is Crucial

The most critical error is allowing the steam generator to boil dry. This can damage the generator and halts the melting process. Always ensure you start with enough water for the batch size you are processing.

Why Steam Protects Your Equipment

Unlike solar melters or direct heating methods that can create intense hot spots, steam provides uniform heat. This prevents the wood of your frames from scorching or warping, extending their usable life.

Optimizing Your Wax Rendering

Your specific goal will determine how you approach the process. Use these guidelines to tailor the operation to your needs.

- If your primary focus is maximizing wax yield: Let the melter run for an extended period, ensuring even the last remnants of wax have melted from the dense slumgum.

- If your primary focus is preserving frame integrity: The steam melter is the ideal choice, as its moist, regulated heat cleans frames thoroughly without the risk of scorching associated with dry heat.

- If your primary focus is efficiency and time savings: Set up your system correctly from the start, ensure the steam generator is adequately filled, and let the automated process work with minimal supervision.

Harnessing steam allows you to turn a time-consuming chore into a simple, productive, and highly effective part of your beekeeping workflow.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1 | Fill Steam Generator | Create a consistent steam source |

| 2 | Load Frames | Prepare wax-laden combs for rendering |

| 3 | Apply Heat | Generate steam to melt wax gently |

| 4 | Monitor Process | Ensure efficient wax flow and separation |

| 5 | Collect Wax | Gather filtered, high-quality beeswax |

| 6 | Cooldown & Cleanup | Maintain equipment and prepare for next use |

Upgrade your beekeeping operation with professional-grade equipment from HONESTBEE.

Our commercial steam wax melters are designed for the high-volume demands of commercial apiaries and distributors, delivering maximum wax yield while preserving the integrity of your valuable frames. Experience the efficiency and reliability that comes from wholesale-focused quality.

Contact our team today to discuss your equipment needs and discover how HONESTBEE can support your business growth.

Visual Guide

Related Products

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- 10L Stainless Steel Electric Honey Press Machine

People Also Ask

- What are the alternative uses for double vats with stainless steel inner barrels? Maximize Your Wax Processing Utility

- What additional function does the Solar Wax Melter serve? Sterilize Hive Frames for Healthier Bees

- What is the temperature performance of a solar wax melter? Optimize Your Yield with Passive Solar Heat

- What function does wax processing and molding equipment serve? Turn Apiary Waste Into High-Value Profit

- What role does beeswax processing equipment play in development of by-products? Turn Apiary Waste into High-Value Profit

- What is the function of the hot water extraction method in beeswax purification? Optimize Wax Quality & Purity

- Why is pressurized drying equipment used for detoxified beeswax? Enhance Foundation Sheet Quality

- What is wax dipping and how does it protect bee equipment? The Ultimate Guide to Long-Lasting Hive Protection