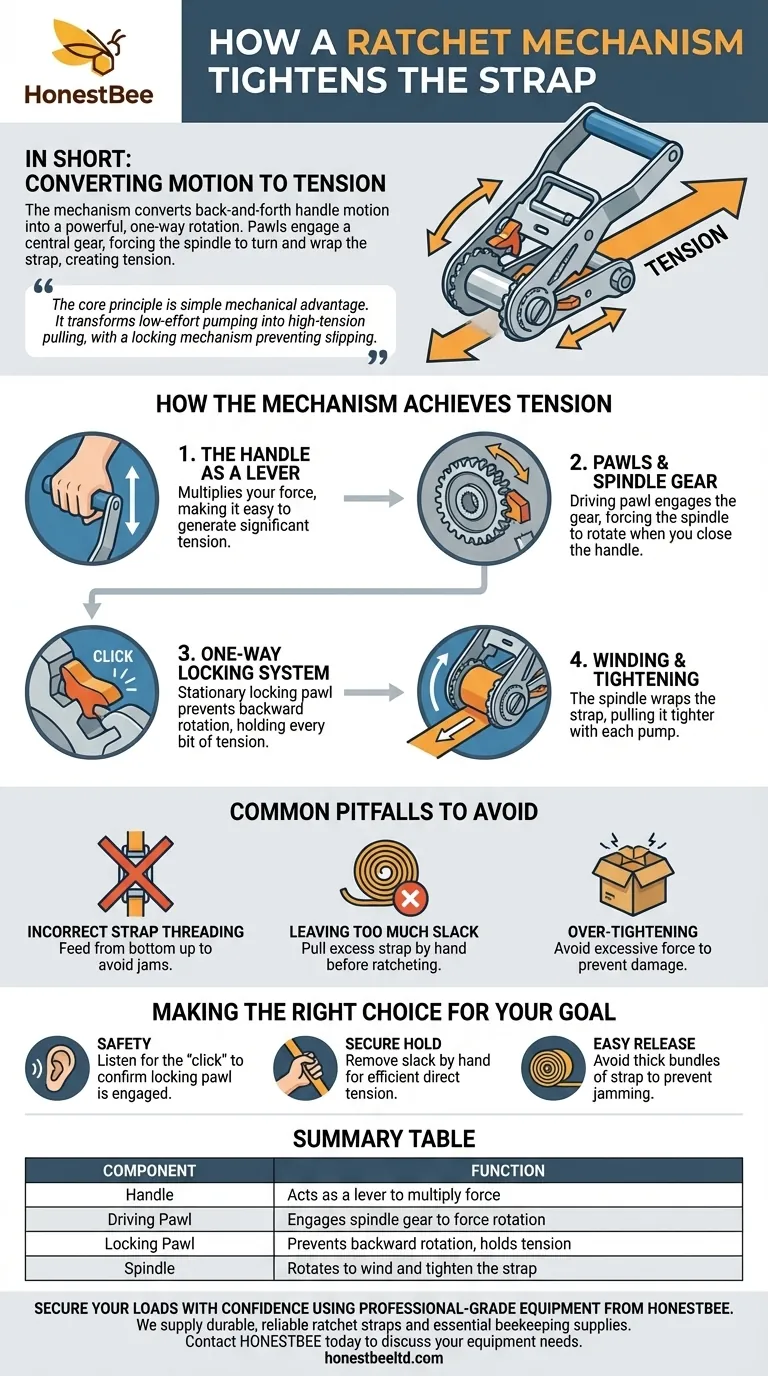

In short, the ratchet mechanism tightens the strap by converting the back-and-forth motion of its handle into a powerful, one-way rotation. As you pump the handle, a set of teeth, or pawls, engage a gear on a central spindle. This action forces the spindle to turn, wrapping the strap around it and systematically removing all slack to create tension.

The core principle is simple mechanical advantage. The ratchet transforms your low-effort handle pumping into a high-tension pulling force, while a locking mechanism prevents it from ever slipping backward until you manually release it.

How the Mechanism Achieves Tension

A ratchet strap is a simple but brilliant machine. Understanding how its components work together makes using it safer and more intuitive.

The Handle as a Lever

The handle you pump is a lever. It multiplies the force you apply, making it easy to generate the significant tension required to secure a heavy load.

The Pawls and the Spindle Gear

When you close the handle, a driving pawl (a small, spring-loaded tooth) engages with the teeth of a gear fixed to the central spindle. This engagement forces the spindle to rotate.

When you open the handle for the next pump, that driving pawl glides back over the gear teeth.

The One-Way Locking System

Crucially, a second, stationary locking pawl is always engaged with the gear. This is the component that makes the distinct "clicking" sound.

This locking pawl prevents the spindle from rotating backward while you open the handle. It ensures that every bit of tension you gain is held securely until the next cycle.

Winding and Tightening

The strap itself is threaded through a slot in the middle of the spindle. As the spindle is forced to rotate in one direction, it wraps the strap's webbing around itself, pulling the strap tighter with each pump of the handle.

Common Pitfalls to Avoid

Understanding the mechanism helps you sidestep common frustrations and use the tool correctly.

Incorrect Strap Threading

The strap must be fed through the spindle's slot from the correct direction. If you feed it from the top down, it will jam. Always feed it from the bottom up, so the strap lies flat as it winds.

Leaving Too Much Slack

Before you start ratcheting, pull all excess strap through by hand until it's taut. Leaving too much slack creates a thick, bulky coil on the spindle.

This can prevent the ratchet from closing and locking properly. In a worst-case scenario, it can become so tightly wound that the release mechanism gets jammed.

Over-tightening

The mechanical advantage of a ratchet is powerful. It is possible to apply enough force to damage the item you are securing, the anchor points, or the strap itself. Tighten until the load is secure, but avoid applying excessive force once it is stable.

Making the Right Choice for Your Goal

Using this knowledge ensures your cargo is secure and your equipment is easy to handle.

- If your primary focus is safety: Always listen for the "click" with each pump to confirm the locking pawl is engaged and holding the tension.

- If your primary focus is a secure hold: Remove as much slack as possible by hand before you begin ratcheting. This allows the mechanism to apply direct tension efficiently.

- If your primary focus is easy release: Avoid winding a thick bundle of strap onto the spindle, as this is the leading cause of a jammed mechanism.

By understanding how these simple parts work together, you transform a potentially frustrating task into a safe and predictable process.

Summary Table:

| Component | Function |

|---|---|

| Handle | Acts as a lever to multiply your force for easy tightening. |

| Driving Pawl | Engages the spindle gear when you close the handle, forcing it to rotate. |

| Locking Pawl | Prevents the spindle from rotating backward, holding the tension securely. |

| Spindle | Rotates to wind the strap, pulling it tight and removing slack. |

Secure your loads with confidence using professional-grade equipment from HONESTBEE.

We supply durable, reliable ratchet straps and other essential beekeeping supplies to commercial apiaries and beekeeping equipment distributors. Our wholesale-focused operations ensure you get the high-quality tools you need to work safely and efficiently.

Contact HONESTBEE today to discuss your equipment needs and discover how we can support your business.

Visual Guide

Related Products

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Engraved Round Hive Number Tags for Beekeeping

- Wholesales Dadant Size Wooden Bee Hives for Beekeeping

- Black Plastic Beetle Barn Hive Beetle Trap for Beehives

People Also Ask

- Why are hive straps important for beekeepers? Secure Your Hives Against Wind, Predators & Transport

- What are the two styles of hive straps? Choose the Right Strap for Your Hive Security

- What is the best length for straps used around beehives? Why 12 Feet is the Industry Standard

- How should a cam buckle strap be installed for optimal performance? Master the Leverage for Maximum Tension

- What is the advantage of using cam buckle straps? Secure Your Load Fast with Simple, Safe Tensioning