After extraction, honey is filtered using materials like fine mesh sieves, cheesecloth, or specialized nylon filters. The primary purpose of this step is to remove physical impurities that are introduced during the extraction process, such as bits of beeswax, propolis, pollen, and even bee parts.

The core decision in filtering is not merely how to clean the honey, but to what extent. The method you choose—from a simple, coarse straining to a fine, multi-stage filtration—directly determines the final character of your honey, balancing raw, pollen-rich authenticity against commercial clarity and a longer shelf life.

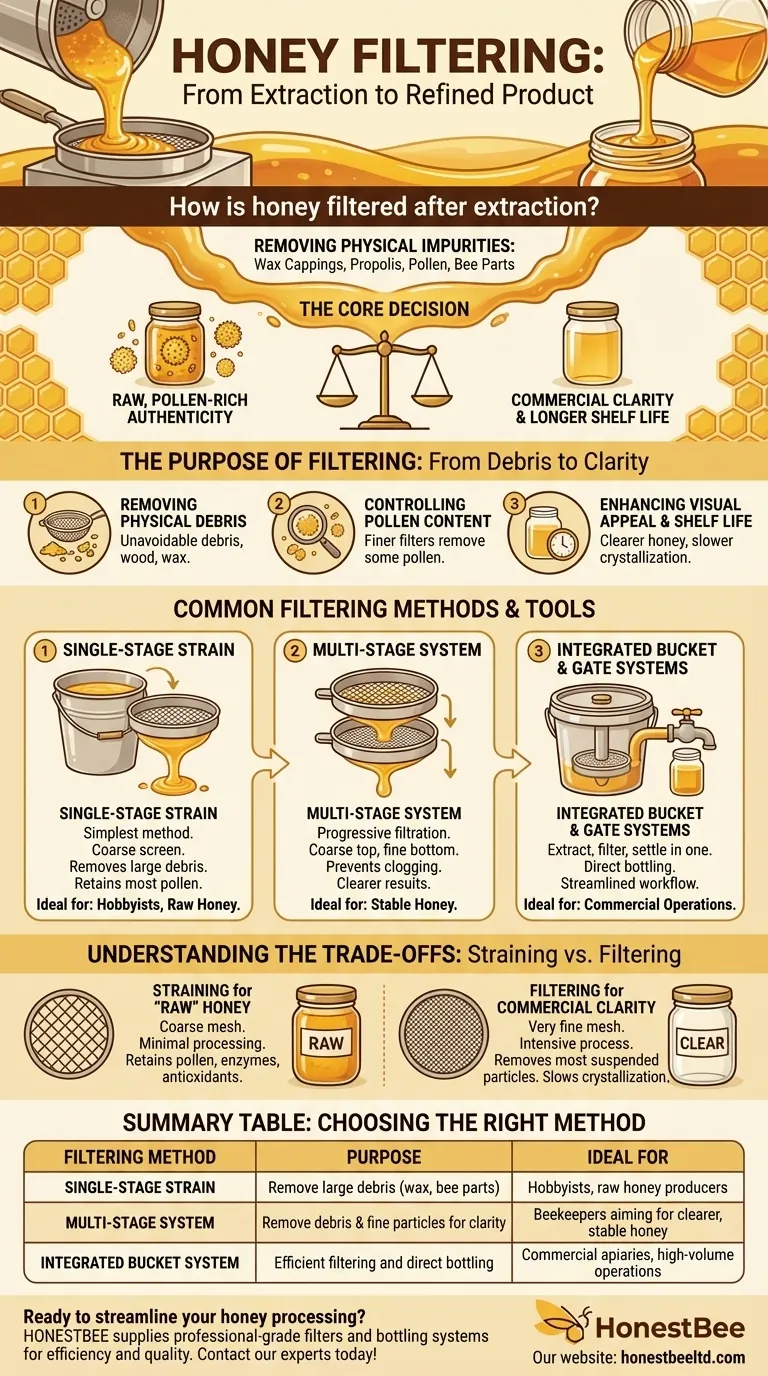

The Purpose of Filtering: From Debris to Clarity

Filtering honey is an optional step, but it's one that most beekeepers perform to refine the final product. The goals can vary significantly, from basic cleanup to preparing honey for a long time on the shelf.

Removing Physical Debris

The most immediate goal of filtering is to remove the unavoidable debris from the uncapping and extraction process. This includes wax cappings, wood splinters from the frames, and any unfortunate bees that didn't make it out. This is the baseline level of cleaning that almost all extracted honey receives.

Controlling Pollen Content

Finer filters can remove suspended particles, including some of the pollen grains. While pollen is a natural and beneficial component of honey, removing it is a common practice in large-scale commercial operations.

Enhancing Visual Appeal and Shelf Life

A honey that has been filtered more finely will appear much clearer and more uniform. This is often preferred by consumers who are accustomed to store-bought honey. An important secondary benefit is that removing fine particles (including pollen and wax) also removes nucleation sites, which can significantly slow down the natural process of crystallization.

Common Filtering Methods and Tools

The tools for filtering range from simple DIY setups to integrated, professional-grade equipment. The principle, however, remains the same: passing honey through a screen.

The Single-Stage Strain

This is the simplest and most common method for hobbyists. It involves pouring extracted honey through a single screen placed over a clean, food-grade bucket.

Common tools for this include a paint strainer bag, a large piece of cheesecloth, or a purpose-made stainless steel honey sieve. This method is excellent for removing large debris while leaving most of the beneficial pollen intact.

The Multi-Stage System

For a cleaner result, many beekeepers use a multi-stage or double-sieve system. This involves stacking two or more filters with progressively finer mesh.

The top, coarser filter catches the large pieces of wax, while the bottom, finer filter catches smaller particles. This prevents the fine filter from clogging quickly and results in a much clearer honey.

Integrated Bucket and Gate Systems

To improve efficiency, many suppliers offer integrated systems. These are typically bottling buckets that have filter inserts and a "honey gate" valve at the bottom.

This setup allows you to extract, filter, and settle the honey in a single container. Once filtering is complete, you can bottle the honey directly from the gate, streamlining the entire workflow.

Understanding the Trade-offs: Straining vs. Filtering

The terms "straining" and "filtering" are often used interchangeably, but in the context of honey, the distinction is critical. Your choice here defines the nature of your final product.

Straining for "Raw" Honey

Straining typically refers to using a coarse mesh to remove only the large, unwanted debris like wax and bee parts. This process is minimal and is designed to clean the honey without removing its core components.

Honey that has only been strained is often marketed as "raw" because it retains the full spectrum of pollen, enzymes, and antioxidants.

Filtering for Commercial Clarity

Filtering, by contrast, often implies a more intensive process using a very fine mesh. This removes not only debris but also most of the suspended pollen and other microscopic particles.

This is standard for large commercial producers because it creates a brilliantly clear product that is slow to crystallize, ensuring a long and stable shelf life. However, this process removes some of the natural elements that define raw honey.

Choosing the Right Method for Your Honey

Your approach should be dictated by the kind of honey you want to produce.

- If your primary focus is producing raw, minimally-processed honey: Use a single, coarse strainer (like a dedicated honey sieve) to remove only large debris while retaining the pollen and natural character.

- If your primary focus is a crystal-clear product with a long shelf life: Employ a multi-stage filtering system with a fine mesh on the bottom layer to remove both large debris and smaller particles.

- If your primary focus is efficiency and convenience for bottling: Invest in an integrated system with a bottling bucket, built-in filters, and a honey gate to streamline the process from filtering to jarring.

Ultimately, the right filtering technique is the one that aligns with your philosophy and the final product you wish to create.

Summary Table:

| Filtering Method | Purpose | Ideal For |

|---|---|---|

| Single-Stage Strain | Remove large debris (wax, bee parts) | Hobbyists, raw honey producers |

| Multi-Stage System | Remove debris & fine particles for clarity | Beekeepers aiming for clearer, stable honey |

| Integrated Bucket System | Efficient filtering and direct bottling | Commercial apiaries, high-volume operations |

Ready to streamline your honey processing? Whether you're a commercial apiary or a beekeeping equipment distributor, HONESTBEE supplies the professional-grade filters and bottling systems you need for efficiency and product quality. Contact our experts today to find the perfect solution for your operation!

Visual Guide

Related Products

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- Professional Thermostatic Conical Honey Melter

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Honeycomb Style Drip Free Honey Dispenser

People Also Ask

- What is the technical mechanism of multi-stage filtration for clear honey? Achieve Market-Leading Purity and Stability

- How does precision filtration equipment affect the quality of propolis extracts? Achieve Purity and Stability

- How do professional fermentation systems guarantee quality? Advanced Filtration for Superior Honey Wine Production

- Why is a precision moisture control filtration system critical for the industrial production of honey? | HONESTBEE Guide

- What is the function of a honey filter machine? Elevate Purity and Commercial Quality for Your Apiary

- What role does honey filtering equipment play in meeting commercial quality standards? Upgrade Your Honey for Export

- What key attributes should industrial honey filtration systems possess? Master High Plant Diversity and Viscosity

- Why is it important to inspect and replace filters in honey filtering equipment? Protect Your Honey Quality & Equipment