To properly use a steam wax melter, you must first fill the steam generator with water, then load your frames into the melter's main chamber. Once the generator is heated, it forces steam through a hose into the chamber, which melts the wax from the honeycomb. The liquid wax then filters through a screen and drains through a tap into a collection container for later use.

A steam wax melter is an efficient tool for rendering beeswax, but its effectiveness is entirely dependent on understanding the process and adhering to critical safety measures. The core principle is simple: use steam's high heat to melt wax, but managing the risks of pressure and burns is non-negotiable.

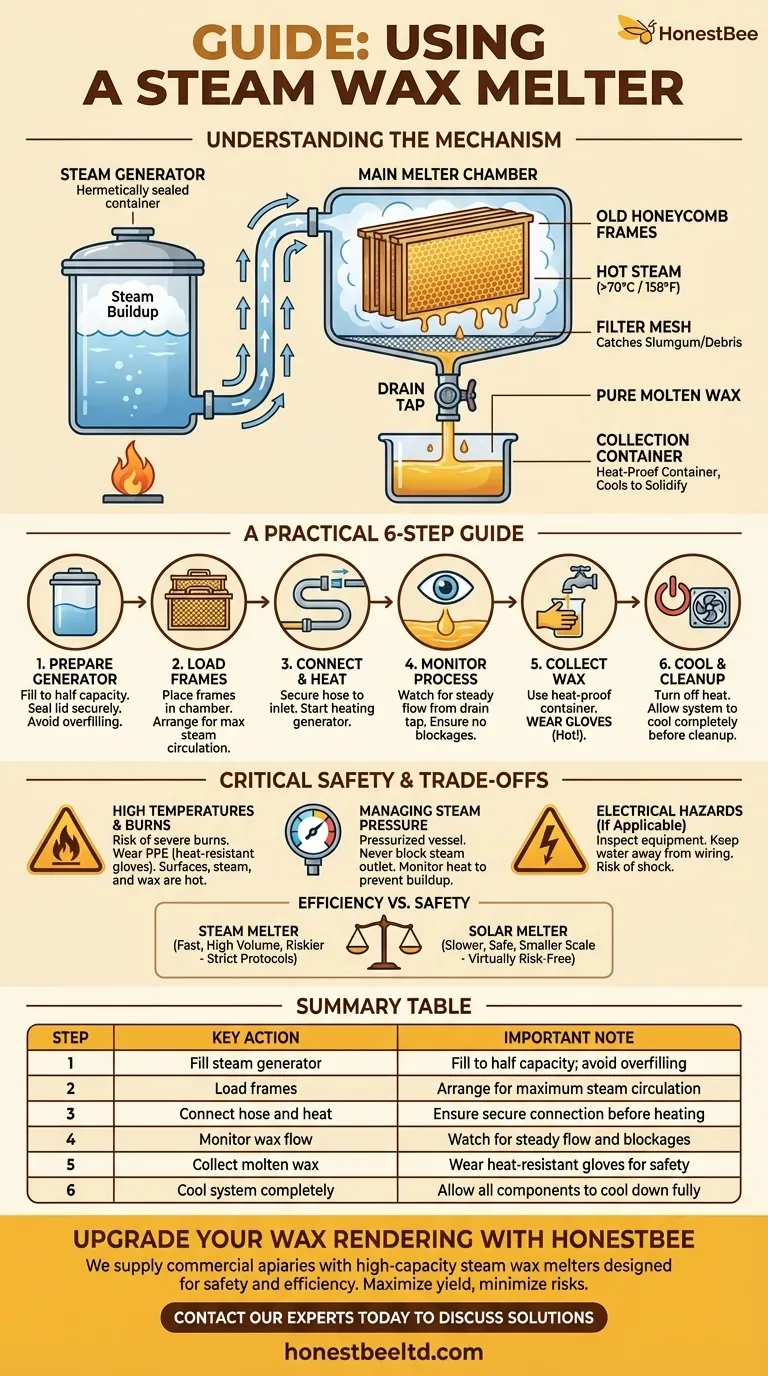

Understanding the Mechanism: How Steam Renders Wax

A steam wax melter operates by harnessing the thermal energy of steam to separate wax from old honeycomb frames. This process is far more efficient than many other methods due to the high temperature of steam.

The Role of the Steam Generator

The system starts with a steam generator, which is a hermetically sealed container. This container is filled partway with water, leaving enough headspace for steam to accumulate as the water boils.

A heat source, such as a fire or an integrated electric element, brings the water to a boil.

How Heat Transfer Works

As steam builds pressure inside the generator, it is forced through a hose connected to the main wax melter chamber. This steam, at a temperature well above the melting point of wax (approximately +70°C or 158°F), envelops the frames.

The hot steam transfers its energy directly to the honeycomb, causing the wax to liquefy rapidly.

Separation and Collection

The molten wax drips down from the frames. Most melter designs include a filter mesh or screen on a pallet at the bottom. This filter catches "slumgum" and other debris while allowing the pure liquid wax to pass through.

The clean, liquid wax then accumulates and flows out of a drain tap into a container you place underneath. Once collected, the wax is left to cool and solidify.

A Practical Guide to Using Your Steam Wax Melter

Follow these steps for a safe and effective rendering session. Always consult your specific model's manual, but these principles apply universally.

Step 1: Prepare the Steam Generator

Fill the steam generator with water to about half of its capacity. Overfilling can reduce steam production efficiency and create a safety risk. Ensure the lid is securely sealed.

Step 2: Load the Frames

Place your old frames, complete with honeycomb, inside the basket or racks of the main wax melter unit. Arrange them to allow for maximum steam circulation.

Step 3: Connect and Heat

Securely attach the hose from the steam generator to the inlet port on the wax melter. Begin heating the water in the generator.

Step 4: Monitor the Process

As the system heats up, you will see melted wax begin to flow from the drain tap. Monitor the process to ensure a steady flow of steam and that the wax is draining properly without blockages.

Step 5: Collect the Rendered Wax

Place a heat-proof container directly under the drain tap to catch the molten wax. Be aware that both the wax and the melter components will be extremely hot.

Step 6: Cooldown and Cleanup

Once the wax flow has stopped, turn off the heat source and allow the entire system to cool down completely. You can then remove the now-clean frames and collect your block of solidified beeswax.

Understanding the Critical Trade-offs

While highly effective, steam wax melters introduce risks that must be managed. Understanding these trade-offs is key to safe operation.

High Temperatures and Burns

The primary hazard is severe burns. The metal surfaces of the melter, the steam itself, and the molten wax are all at dangerously high temperatures. Always wear appropriate personal protective equipment (PPE), including heat-resistant gloves.

Managing Steam Pressure

The steam generator is a pressurized vessel. Excessive heating without a proper outlet can cause a dangerous pressure buildup, potentially leading to a rupture of the container or the hose. Never block the steam outlet and monitor the heating level closely.

Electrical Hazards (If Applicable)

For electric models, there is a risk of electric shock, especially if the heating element is damaged or if water comes into contact with wiring. Always inspect your equipment before use.

Efficiency vs. Safety

Compared to a solar wax melter, a steam melter is significantly faster and has a much larger capacity. However, solar melters are inherently safer as they operate at lower temperatures and without pressure, making them a viable, albeit slower, alternative for smaller-scale beekeepers.

Making the Right Choice for Your Goal

Your choice of equipment should align directly with your operational needs and safety tolerance.

- If your primary focus is maximum efficiency and volume: A steam wax melter is the superior choice for processing a large number of frames quickly, provided you adhere to strict safety protocols.

- If your primary focus is ultimate safety and simplicity: A solar wax melter is a slower but virtually risk-free alternative that is well-suited for smaller apiaries or hobbyists.

By understanding both the process and the principles, you can render your beeswax safely and effectively.

Summary Table:

| Step | Key Action | Important Note |

|---|---|---|

| 1 | Fill steam generator with water | Fill to half capacity; avoid overfilling |

| 2 | Load frames into main chamber | Arrange for maximum steam circulation |

| 3 | Connect hose and heat generator | Ensure secure connection before heating |

| 4 | Monitor wax flow from drain tap | Watch for steady flow and blockages |

| 5 | Collect molten wax in heat-proof container | Wear heat-resistant gloves for safety |

| 6 | Cool system completely before cleanup | Allow all components to cool down fully |

Ready to upgrade your wax rendering process with professional-grade equipment?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with high-capacity steam wax melters designed for safety and efficiency. Our wholesale-focused operations ensure you get durable, reliable equipment that maximizes your wax yield while minimizing risks.

Contact our experts today to discuss the best wax melting solutions for your commercial operation!

Visual Guide

Related Products

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Professional Rolling Wax Cutter with Ergonomic Handle

People Also Ask

- What is the process for purifying beeswax after removing it from a hive? A Simple Two-Stage Method for Pure Wax

- How does the machine flatten the beeswax? A Guide to Roller and Press Methods

- Why might a commercial beekeeper prefer an electric beeswax melter? Maximize Profit with Speed & Scale

- What are the steps involved in preparing wax sheets for milling? Master Temperature Control for Perfect Foundation

- What is the final step in making beeswax foundation sheets? Achieving Perfect Fit for a Productive Hive