From a purely environmental standpoint, styrofoam beehives are considered healthier for bees primarily because of their superior thermal insulation. This single property dramatically reduces the energy bees must expend to regulate their internal nest temperature, leading to lower moisture levels, reduced winter stress, and less exposure to the chemical treatments often required to maintain wooden equipment.

The core issue is energy management. A bee colony's ability to thrive depends on how efficiently it can control its environment. Styrofoam hives act like a well-insulated home, freeing up the colony's energy from climate control to focus on raising brood, fighting disease, and producing honey.

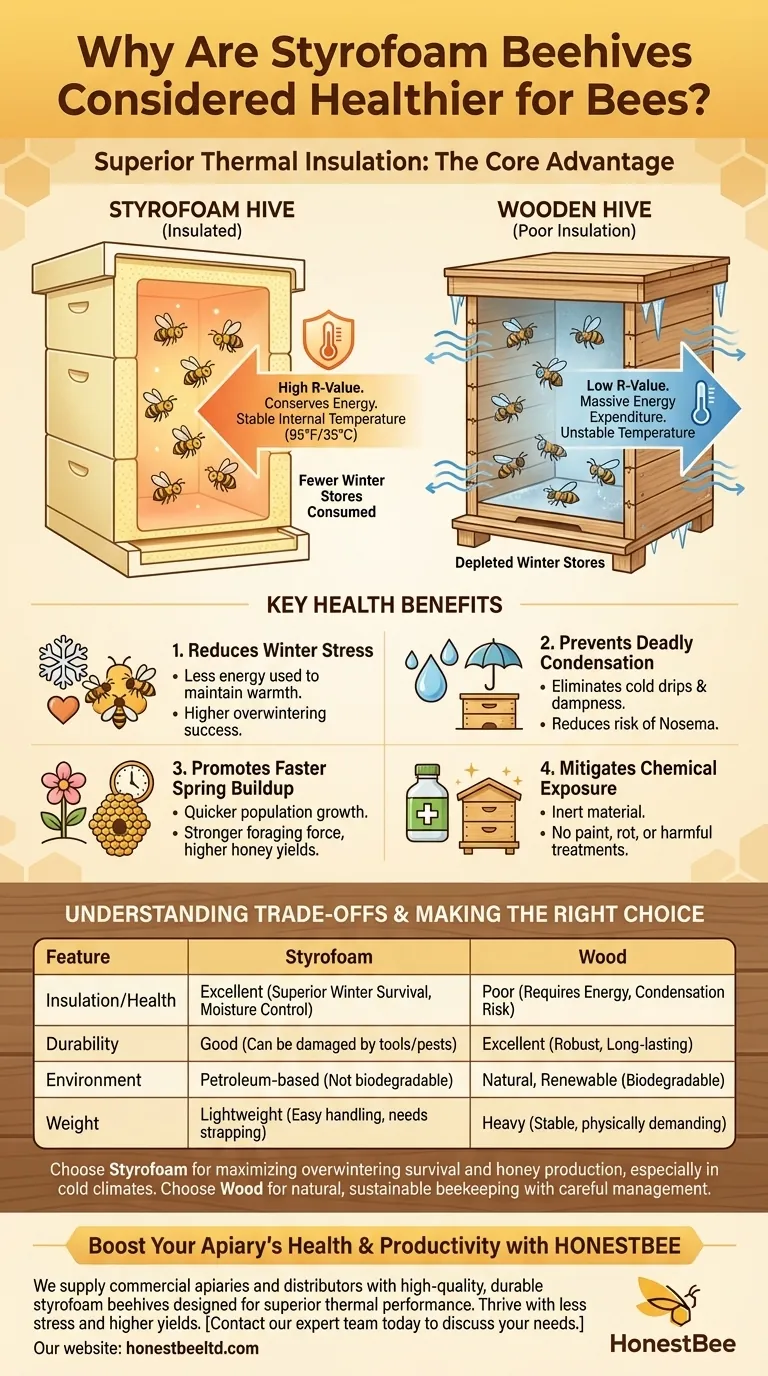

The Core Advantage: Superior Thermal Regulation

The most significant health benefit of styrofoam hives stems from their high R-value, or thermal resistance, which far exceeds that of wood. This directly impacts the colony's ability to survive and prosper.

Reducing Winter Stress

A honeybee colony's primary job in winter is to maintain the temperature of its central cluster at around 95°F (35°C). In a poorly insulated wooden hive, this requires a massive and constant expenditure of energy, consumed in the form of honey.

Styrofoam’s insulation drastically lessens this energy burden. With less heat escaping, the colony consumes fewer winter stores, emerging in the spring with a larger population and more resources, which directly contributes to higher overwintering success rates.

Preventing Deadly Condensation

A cluster of bees releases a significant amount of water vapor through respiration. In a wooden hive, this warm, moist air rises and hits the cold inner walls and cover, causing condensation to form.

This cold moisture can drip back down onto the bees, chilling and killing them. It also creates a damp environment ideal for pathogens like Nosema, a serious gut disease in bees. Styrofoam’s warm interior surfaces prevent this condensation cycle, keeping the hive drier and healthier.

Promoting Faster Spring Buildup

A colony that survives winter with a larger population and more food reserves can begin raising new brood earlier and more rapidly in the spring. This is known as the "spring buildup."

Styrofoam hives facilitate a quicker buildup, leading to a more powerful foraging force ready for the first major nectar flows. This often translates directly into higher honey production, with some studies showing yields over 35% greater than in wooden hives.

Mitigating Chemical and Pest Exposure

Beyond climate control, hive material influences the colony's direct exposure to external chemicals and pests.

Eliminating Wood-Related Treatments

Wood is a natural material susceptible to rot, warping, and pests like woodworms. To prolong its life, beekeepers must often paint or treat wooden hive bodies with preservatives.

Styrofoam is inert and does not rot. It requires no paint or chemical treatments, eliminating the risk of these substances leaching into the hive and harming the bees.

The Legacy of Old Equipment

This issue is particularly relevant when acquiring used equipment. Decades ago, it was common practice to treat wooden hives with potent chemicals like Creosote, which are now known to be harmful and have been phased out. An older wooden hive may carry a legacy of these dangerous treatments.

Understanding the Trade-offs

While styrofoam offers clear health advantages for the colony, it is not without its own set of challenges and considerations.

Durability and Handling

Wood is heavy and robust, capable of withstanding decades of rough handling. High-density polystyrene is durable, but it can be more easily damaged by hive tools or pests like wax moths and mice if not properly managed.

Environmental Impact

This is a significant factor for many beekeepers. Wood is a natural, renewable, and biodegradable resource. Expanded polystyrene (EPS), or styrofoam, is a petroleum-based plastic that is not biodegradable, posing a long-term environmental concern.

Weight and Stability

The lightweight nature of styrofoam is an advantage for the beekeeper's back, but it can be a disadvantage in the apiary. These hives are more susceptible to being blown over in high winds and often need to be strapped down for security.

Making the Right Choice for Your Goal

The decision between wood and styrofoam depends entirely on your specific climate, management style, and beekeeping philosophy.

- If your primary focus is maximizing overwintering survival in cold climates: Styrofoam is the superior choice due to its unmatched insulation and moisture control.

- If your primary focus is maximizing honey production: The energy savings and faster buildup in a styrofoam hive often translate directly into higher honey yields.

- If your primary focus is natural beekeeping and sustainability: Traditional wooden hives remain the standard, provided they are managed carefully to control moisture and sourced from reputable suppliers.

Ultimately, a healthy colony is the result of good management, and the hive is a critical tool that can either support or hinder those efforts.

Summary Table:

| Health Benefit | How Styrofoam Helps Bees |

|---|---|

| Winter Survival | Superior insulation reduces energy expenditure, preserving colony strength and food stores. |

| Moisture Control | Prevents deadly condensation, reducing risk of diseases like Nosema. |

| Spring Buildup | Colonies build up faster, leading to stronger foraging forces and higher honey yields. |

| Chemical Exposure | Inert material requires no chemical treatments, eliminating risk of contamination. |

Ready to boost your apiary's health and productivity?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with high-quality, durable styrofoam beehives designed for superior thermal performance. Our wholesale-focused operations ensure you get the equipment you need to help your colonies thrive with less stress and higher yields.

Contact our expert team today to discuss your needs and discover how our beekeeping solutions can benefit your operation.

Visual Guide

Related Products

- Professional Insulated Winter Hive Wrap for Beekeeping

- Professional Insulated Plastic Bee Hives

- Honey Flow Garden Bee Hive Flow Hive Best Beehive for Beginners

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

People Also Ask

- How do the insulation qualities of EPS bee hives benefit bees? Maximize Colony Health and Honey Yield

- What are the environmental benefits of EPS bee hives? Boost Colony Health and Reduce Your Eco-Footprint

- How do polystyrene beehives reduce the risk of starvation in honeybee colonies during winter? Superior Insulation for Winter Survival

- What are the benefits of using polystyrene beehives for thermal regulation? Maximize Winter Survival & Spring Growth

- How do high-insulation foam beehives contribute to colony productivity in extreme climates? Boost Honey Yields Today

- What makes polyurethane foam environmentally friendly? The Surprising Benefits of a Durable, Inert Material

- What is the technical value of using lightweight beehives? Optimize Insulation and Ergonomics in Your Apiary

- Is polyurethane foam considered an environmentally friendly and safe material? Expert Guide to Polyurethane Safety