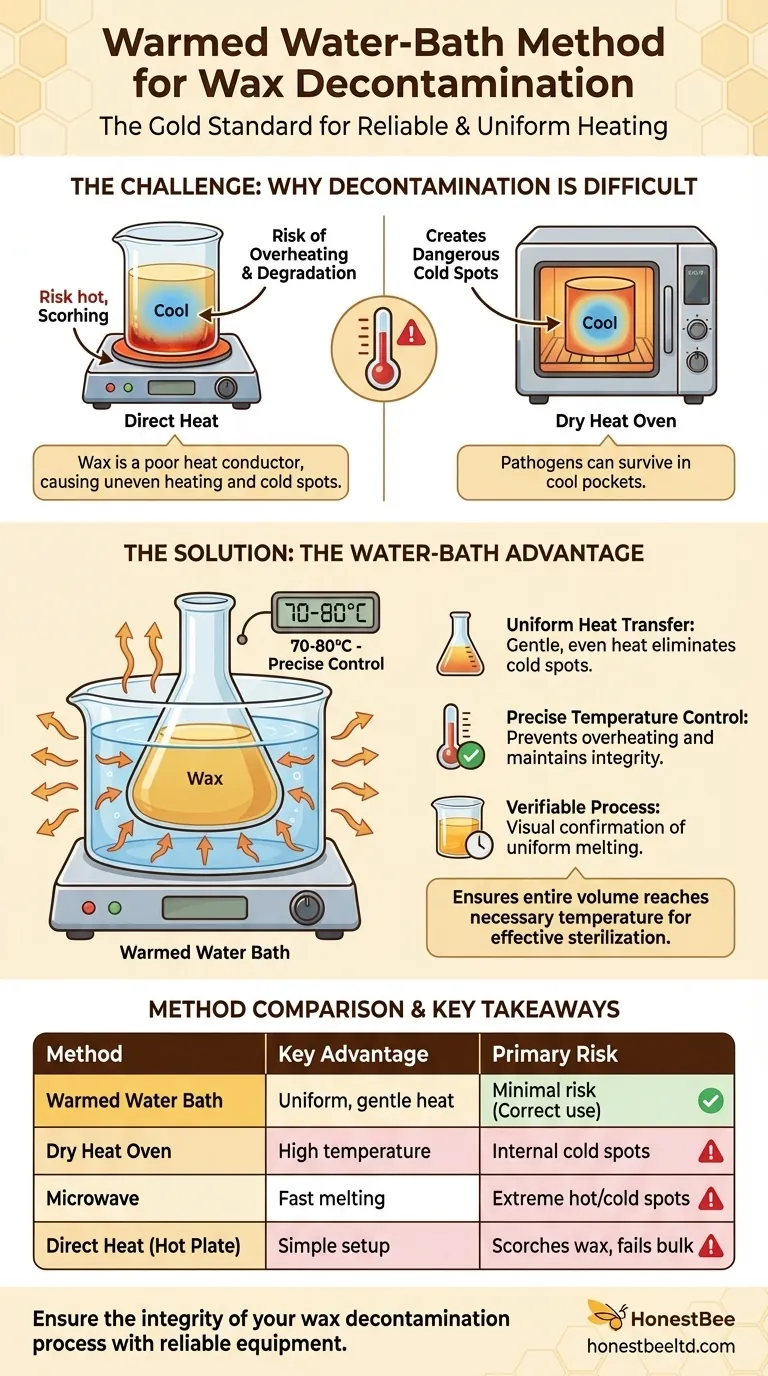

The warmed water-bath method is the gold standard for decontaminating wax because it provides the most reliable and uniform heating. Unlike other methods that can create dangerous hot spots or leave internal cold spots, a water bath ensures the entire volume of wax reaches the necessary temperature, which is critical for neutralizing contaminants effectively.

The core challenge in wax decontamination is not merely melting it, but ensuring every particle reaches and holds a specific temperature to guarantee sterilization. The water-bath method is preferred because its gentle, consistent heat transfer eliminates the cold spots and overheating risks that undermine the safety and integrity of other techniques.

The Core Problem: Why Decontaminating Wax is Uniquely Challenging

To understand the preference for a water bath, you must first appreciate the physical properties of wax that make decontamination so difficult.

Wax is a Poor Heat Conductor

Wax acts as an excellent insulator. When you apply heat from a single source, like a dry oven or a hot plate, the exterior heats up much faster than the interior.

This creates a significant temperature gradient, where the outside might be scorching hot while the center remains too cool to neutralize pathogens.

The Risk of "Cold Spots"

These cooler areas, or cold spots, in the center of the wax block are the primary point of failure in decontamination.

Microorganisms like bacteria or heat-resistant spores can survive within these pockets, rendering the entire process useless and creating a significant contamination risk for subsequent use.

The Danger of Overheating and Degradation

Conversely, aggressive heating methods like microwaves or direct hot plates can easily overheat portions of the wax.

This not only degrades the wax's chemical structure and performance characteristics but can also be a fire hazard or release noxious fumes.

How the Water Bath Solves the Decontamination Puzzle

The warmed water-bath method directly addresses the challenges of insulation and temperature control through several key principles.

Principle 1: Uniform Heat Transfer

Water is a highly efficient medium for transferring heat gently and uniformly. By immersing the wax container in heated water, heat is applied evenly from all sides simultaneously.

This process, known as conduction, slowly and consistently raises the temperature of the entire wax block, virtually eliminating the risk of internal cold spots.

Principle 2: Precise Temperature Control

Laboratory water baths allow for extremely precise temperature regulation. You can set the bath to the exact temperature required for decontamination (e.g., 70-80°C) and hold it there for the necessary duration.

This prevents the wax from ever exceeding a safe temperature, protecting its integrity and preventing scorching.

Principle 3: A Verifiable Process

The method allows for a clear, observable endpoint. Once the entire block of wax is fully molten within the water bath, you have a strong visual confirmation that it has reached a uniform temperature throughout.

Holding it in this liquid state for the prescribed time provides high confidence that the decontamination process has been completed successfully across the entire batch.

Understanding the Trade-offs: Water Bath vs. Other Methods

While the water-bath method is superior for decontamination, it's useful to understand why other common methods fall short for this specific task.

Dry Heat Ovens

A dry air oven relies on convection, which is far less efficient at transferring heat into an insulator like wax. This results in highly uneven heating and makes it almost impossible to guarantee the core of the wax has reached the target temperature.

Microwaves

Microwaves heat by agitating water molecules. While fast, this process is notoriously uneven, creating extreme hot spots and cold spots. It is not a reliable method for sterilization and poses a risk of superheating and splattering.

Direct Heat (Hot Plates)

Placing a container of wax on a hot plate creates intense bottom-up heat. This will scorch and burn the bottom layer of wax long before the top even begins to melt, destroying the material and failing to decontaminate the bulk of it.

Making the Right Choice for Your Process

Your choice of heating method should be dictated by the required level of safety and process integrity for your application.

- If your primary focus is validated decontamination (e.g., in laboratory, dental, or medical settings): The warmed water-bath method is non-negotiable, as it is the only technique that ensures uniform, controllable heating.

- If your goal is simply to melt clean, non-contaminated wax for a non-critical task: Faster methods may be acceptable, but you must tolerate the risk of uneven melting and potential damage to the wax.

- If you are considering any method other than a water bath for decontamination: You must have a robust validation protocol to prove that the entire volume of wax reached and maintained the sterilization temperature, which is often impractical.

Ultimately, choosing the right method is about managing risk and guaranteeing the effectiveness of your decontamination protocol.

Summary Table:

| Method | Key Advantage | Primary Risk for Decontamination |

|---|---|---|

| Warmed Water Bath | Uniform, gentle heat transfer from all sides | Minimal risk when used correctly |

| Dry Heat Oven | High temperature capability | Creates internal cold spots in insulating wax |

| Microwave | Fast melting | Extreme hot and cold spots; unreliable sterilization |

| Direct Heat (Hot Plate) | Simple setup | Scorches wax; fails to heat the entire volume |

Ensure the integrity of your wax decontamination process with reliable equipment from HONESTBEE.

As a leading supplier to commercial apiaries and beekeeping equipment distributors, we understand that effective decontamination is critical for maintaining hive health and product quality. Our wholesale-focused operations provide the durable, precise equipment you need to implement the gold-standard water-bath method with confidence.

Let us help you build a safer, more reliable process. Contact our experts today to discuss your needs and our range of beekeeping supplies.

Visual Guide

Related Products

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Professional Thermostatic Conical Honey Melter

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

People Also Ask

- What are the steps involved in preparing wax sheets for milling? Master Temperature Control for Perfect Foundation

- How to clean wax after extracting honey? Master the Cold Wash vs. Melting Methods

- What is beeswax and why is it valuable? Discover Its Versatility for Your Business

- Why might a commercial beekeeper prefer an electric beeswax melter? Maximize Profit with Speed & Scale

- What are the advantages of using industrial wax melters for beeswax? Achieve Scalable, Safe, and Consistent Production