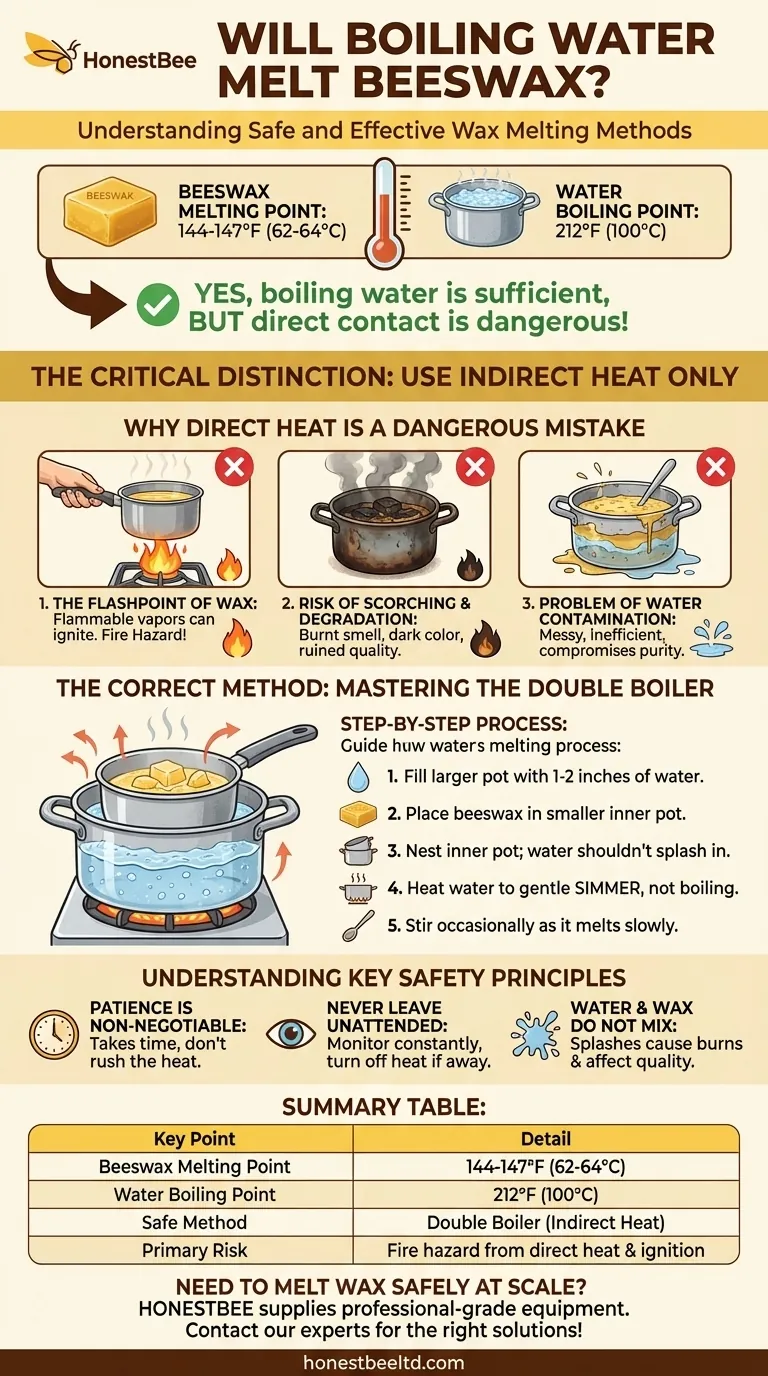

Yes, the heat from boiling water is more than sufficient to melt beeswax. Beeswax typically melts between 144-147°F (62-64°C), while water boils at 212°F (100°C). However, you should never place beeswax directly into boiling water or over a direct flame, as this is both dangerous and can ruin the wax.

The critical distinction is not if boiling water can melt wax, but how it should be used. The only safe and effective method is to use simmering water as an indirect heat source in a double boiler, which prevents the flammable wax from overheating and igniting.

Why Direct Heat is a Dangerous Mistake

Placing beeswax directly over a high heat source is a common but hazardous error. Understanding the risks involved is the first step toward handling this material correctly.

The Flashpoint of Wax

Beeswax is a flammable, oil-based substance. When heated too quickly or to an excessive temperature, it can release flammable vapors that can ignite, potentially causing a dangerous fire.

Risk of Scorching and Degradation

Direct, intense heat doesn't just pose a fire risk; it also degrades the quality of the wax. This can scorch the beeswax, giving it a burnt smell and a darkened color, rendering it unsuitable for most projects.

The Problem of Water Contamination

If you were to place beeswax directly into boiling water, the two would mix. Separating the melted wax from the water later is a messy, inefficient process that can compromise the purity and texture of your final product.

The Correct Method: Mastering the Double Boiler

The universally recommended technique for melting beeswax safely is the double boiler method. This approach uses gentle, indirect heat to melt the wax evenly and without risk.

How It Works

A double boiler consists of a smaller pot or heat-proof container that sits inside a larger pot of water. The water in the outer pot is heated, and the resulting steam and hot water gently transfer heat to the inner pot, melting the wax.

This method ensures the wax never comes into contact with the direct flame or heating element, keeping its temperature from rising too quickly.

Step-by-Step Process

- Fill your larger pot with one to two inches of water.

- Place your beeswax (in chunks, pellets, or pastilles) into the smaller, inner pot.

- Nest the smaller pot inside the larger one. The water should surround the bottom of the inner pot but not be high enough to splash into it.

- Heat the water on medium until it reaches a gentle simmer, not a rolling boil.

- Stir the beeswax occasionally with a dedicated utensil as it melts slowly and evenly.

Understanding the Key Safety Principles

Even when using the correct method, safety must remain your top priority. Melting wax is a straightforward process, but it is not one to be taken lightly.

Patience is Non-Negotiable

Melting wax properly takes time, potentially 30 minutes or more depending on the volume. Rushing the process by increasing the heat defeats the purpose of the double boiler and reintroduces risk.

Never Leave Melting Wax Unattended

This is the most important rule. A pot of melting wax should be monitored at all times. If you must step away, turn off the heat.

Water and Wax Do Not Mix

Be careful not to splash any water from the bottom pot into your melting wax. This can cause the hot wax to bubble and splatter, which is a burn hazard. It also introduces moisture that can negatively affect candles or cosmetic products.

Making the Right Choice for Your Project

Your approach should be guided by safety and the quality of your desired outcome.

- If your primary focus is safety and quality: Always use a double boiler or a dedicated electric wax melter with temperature controls.

- If you are working with a small amount of wax for a one-off project: A simple DIY double boiler using two saucepans is a perfectly effective and safe solution.

- If you plan to melt wax frequently or in larger volumes: Investing in a purpose-built wax melter is the most efficient and safest long-term option.

By respecting the properties of the material and using controlled, indirect heat, you can safely melt beeswax for any application.

Summary Table:

| Key Point | Detail |

|---|---|

| Beeswax Melting Point | 144-147°F (62-64°C) |

| Water Boiling Point | 212°F (100°C) |

| Safe Method | Double Boiler (Indirect Heat) |

| Primary Risk | Fire hazard from direct heat and wax ignition |

Need to melt wax safely and efficiently at scale? HONESTBEE supplies professional-grade beekeeping supplies and equipment, including safe and reliable wax melters, to commercial apiaries and beekeeping equipment distributors. Ensure the quality and safety of your operations—contact our experts today to find the right equipment for your needs!

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

People Also Ask

- What are wax melters used for? Unlock Efficient Wax Processing for Your Business

- What factors should be considered when choosing a wax melter? Optimize Your Beekeeping Efficiency

- What temperature range is considered gentle heat for melting beeswax? Preserve Aroma & Color

- What is the flash point of beeswax, and why is it important? Essential Safety Guide for Beekeepers

- How do you pour melted beeswax into a mold? A Step-by-Step Guide for a Flawless Finish