It’s a scenario every successful honey producer dreads. A major distributor places a purchase order that could redefine your year, but your facility is already running at full tilt. Your team is working overtime, running multiple small batches back-to-back, just to keep up with existing demand. You have the honey, you have the market, but you’re stuck. You’ve hit a production ceiling, and the culprit is often the one piece of equipment at the heart of your operation: your mixing tank.

Working Harder, Not Smarter: The High Cost of a Mismatched Tank

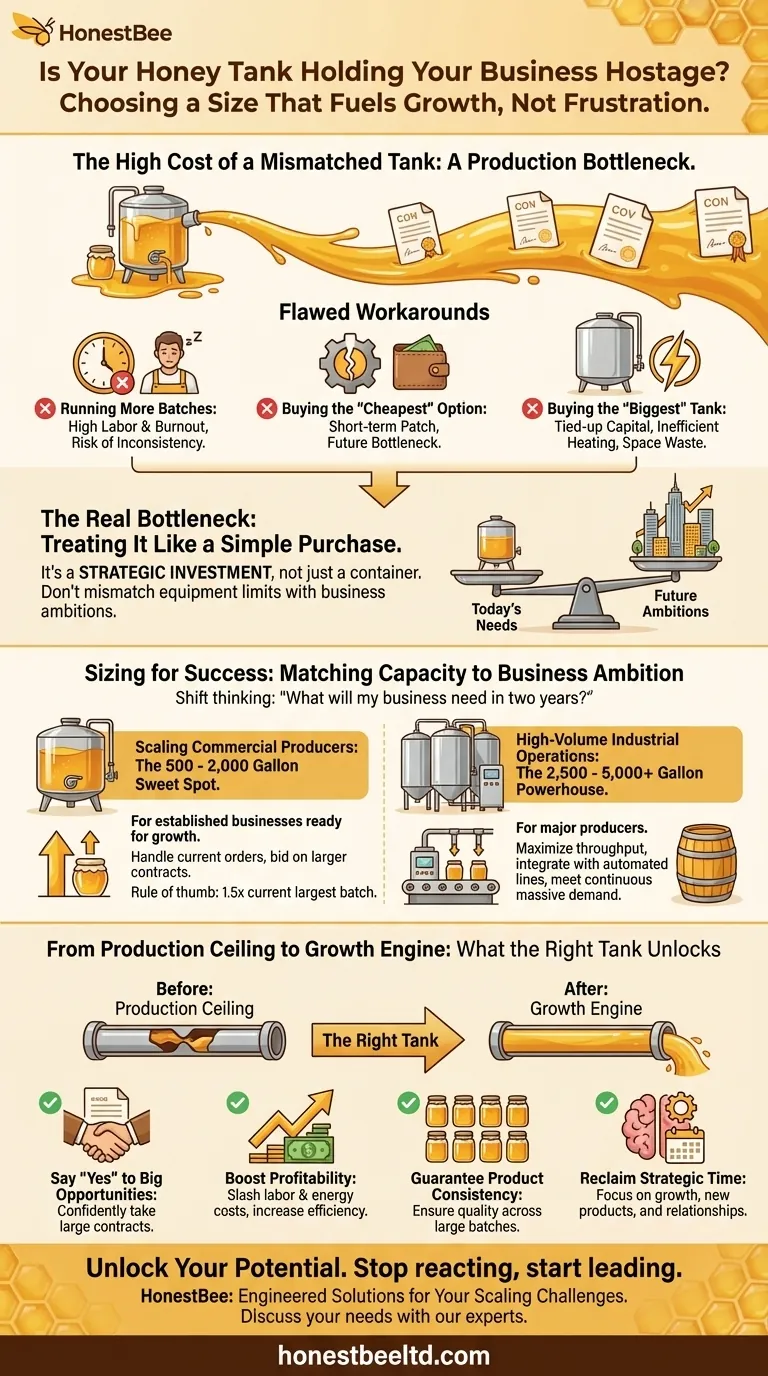

This feeling of being "stuck" is incredibly common in growing apiaries. When faced with a production bottleneck, operators often resort to a few predictable, but ultimately flawed, workarounds:

- Running More Batches: This seems like the obvious fix, but it's a trap. It dramatically increases labor costs, introduces a higher risk of inconsistency between batches, and leads to team burnout. You're constantly in a reactive mode, never able to get ahead.

- Buying the "Cheapest" Option: A small, low-cost tank might solve today's problem, but it guarantees you'll be facing the exact same bottleneck in six to twelve months. It's a short-term patch, not a long-term solution.

- Buying the "Biggest" Tank Possible: Oversizing can be just as damaging. You tie up huge amounts of capital in an asset you can't fully utilize. Heating a small batch in a 3,000-gallon tank is incredibly inefficient, driving up energy costs. That oversized tank also consumes valuable floor space that could be used for other critical functions.

These "solutions" all lead to the same negative business outcomes: missed opportunities for large contracts, strained profit margins from high operational costs, and a brand reputation at risk due to potential inconsistencies. Your business growth stalls, not for a lack of demand, but for a lack of a core piece of infrastructure.

The Real Bottleneck: Treating a Strategic Investment Like a Simple Purchase

Here is the fundamental truth: the frustration and inefficiency aren't caused by your team or your honey. The problem is rooted in treating your mixing tank selection as a simple purchase rather than a strategic business decision.

The common workarounds fail because they only address the symptom—the immediate need for more capacity. They don't address the root cause: a fundamental mismatch between your equipment’s physical limits and your business’s future ambitions.

A mixing tank isn't just a container; it's the engine of your production line. Its capacity dictates your maximum throughput, your operational efficiency, and your ability to scale. Choosing a tank based on today’s average batch size is like building a highway with only one lane when you know a city is being built at the end of it. A bottleneck is inevitable.

Sizing for Success: Matching Tank Capacity to Business Ambition

To truly solve this problem, you need to shift your thinking from "What tank do I need today?" to "What tank will my business need in two years?" The solution is to invest in a tank that is intentionally sized not just for your current needs, but for your projected growth.

This is where having a range of purpose-built options becomes critical. A truly strategic choice is based on your operational scale and future goals:

For Scaling Commercial Producers: The 500 - 2,000 Gallon Sweet Spot

This range is the workhorse for established businesses ready for significant growth. A tank in this category allows you to handle your current orders with ease while providing the capacity to confidently bid on and win the larger contracts that will define your future. A good rule of thumb is to select a tank that can handle at least 1.5 times your current largest batch.

For High-Volume Industrial Operations: The 2,500 - 5,000+ Gallon Powerhouse

For major producers and packers, maximizing throughput is everything. These tanks are designed for integration into fully automated lines, ensuring you can meet massive, continuous demand without interruption. This isn’t just a tank; it’s the cornerstone of an industrial-scale processing system.

At HONESTBEE, we supply a comprehensive range of mixing tanks precisely because we understand they are not one-size-fits-all. Our equipment is engineered to be a direct solution to the strategic challenge of scaling, providing the specific tool you need to break through your production ceiling.

From Production Ceiling to Growth Engine: What the Right Tank Unlocks

When your tank is no longer a bottleneck, it transforms into a growth engine. The change impacts your entire business. Suddenly, you can:

- Say "Yes" to Big Opportunities: Take on that large retail contract without wondering how you'll manage fulfillment.

- Boost Profitability: Slash labor and energy costs by running a single, highly efficient large batch instead of multiple smaller ones.

- Guarantee Product Consistency: Ensure every jar from a 1,500-gallon run has the exact same quality, strengthening your brand's reputation.

- Reclaim Strategic Time: Free your team from the constant pressure of "keeping up" so they can focus on what's next—developing new products, optimizing distribution, and building customer relationships.

Choosing the right mixing tank is one of the most powerful levers you can pull to unlock your business's potential. It’s the decision that allows you to stop reacting to the market and start leading it.

Your honey operation has the potential to grow, but it needs the right infrastructure to support that expansion. If you're tired of hitting a production wall, let's talk about building a more efficient and scalable future. Our team can help you analyze your current workflow and future goals to identify the perfect equipment solution. To discuss the specific challenges and opportunities within your operation, Contact Our Experts.

Visual Guide

Related Products

- Professional Honey Storage Tank with Agitation System

- Stainless Steel Honey Storage and Settling Tank with Double Strainer

- Stainless Steel Honey Storage Tank with Lid for Honey

- Stainless Steel Heated Honey Tank Warming Heating Tank

- Stainless Steel Uncapping Tank with Stand and Strainer

Related Articles

- From Hive to Jar: The Elegant Engineering of a Simple Honey Strainer

- How to Prevent and Manage Honey Crystallization in Flow Hives: A Beekeeper’s Guide

- Beyond the Strainer: The Engineering of Trust in Commercial Honey Production

- Optimizing Honey Filtration: How Mesh Sizes Shape Quality and Market Appeal

- Is Your Honey Tank a Hidden Hazard? Why Poor Sanitation Can Spoil Your Harvest