Every spoonful of honey represents months of careful nectar collection by bees—and days of critical decision-making by beekeepers. Harvest too early, and fermentation ruins your batch; wait too long, and you risk losing yield to pests or crystallization. This guide reveals the science-backed methods commercial apiaries use to pinpoint harvest time and maintain honey quality through precise moisture control.

Understanding Honey Fermentation Risks

The Science Behind Moisture and Fermentation

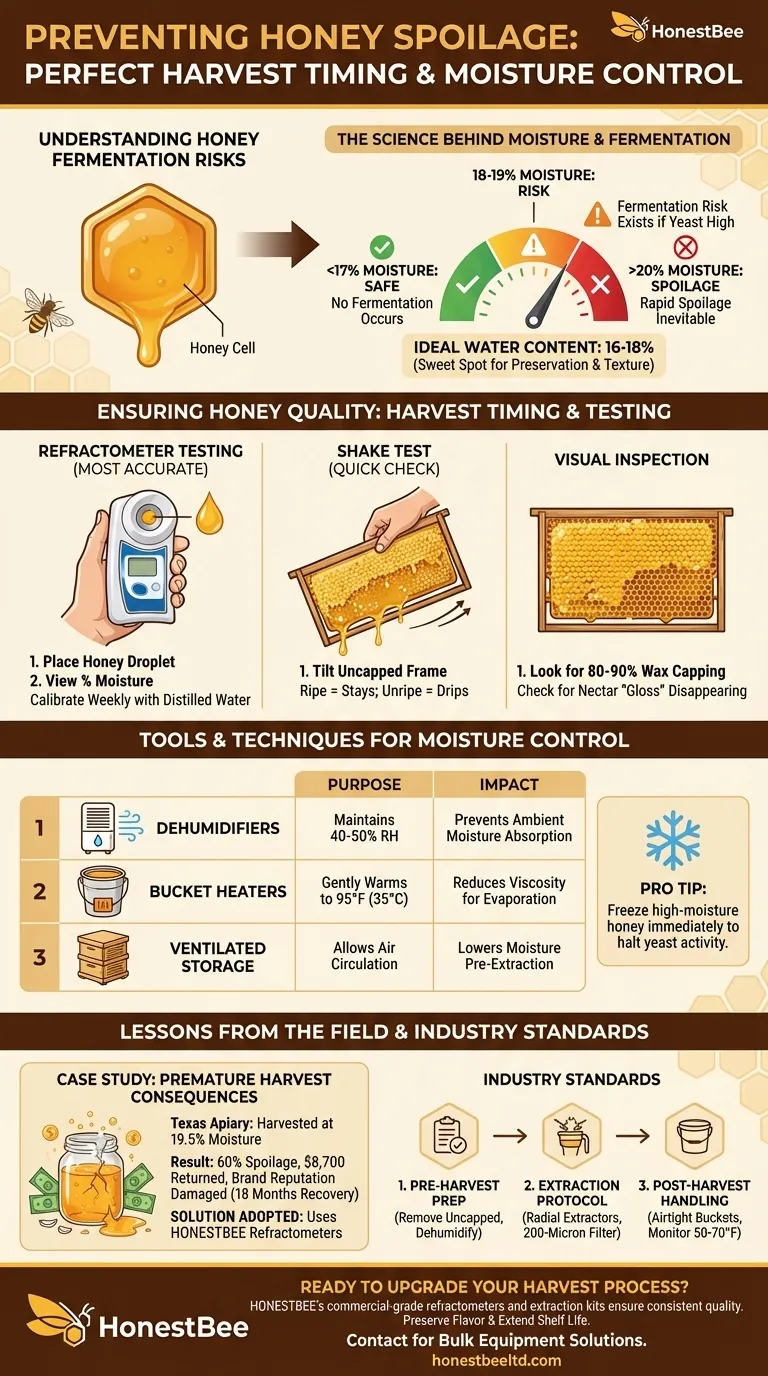

Honey’s natural preservative properties rely on its low water content. When moisture levels exceed 18%, naturally occurring yeasts activate, converting sugars into alcohol and carbon dioxide. Research shows:

- Below 17% moisture: No fermentation occurs

- 18-19% moisture: Fermentation risk exists if yeast populations are high

- Above 20% moisture: Rapid spoilage becomes inevitable

Climatic factors like wet springs or humid extraction environments frequently elevate moisture beyond safe thresholds.

Critical Thresholds: Ideal Water Content for Harvest

Commercial operations target 16-18% water content—the sweet spot between preservation and texture. Beekeepers achieve this through:

✔️ Monitoring hive humidity with hygrometers

✔️ Avoiding harvest during rainy periods

✔️ Controlling extraction-room conditions

"We lost 300 lbs of honey last season by harvesting after a thunderstorm. Now we test every frame with a refractometer before extraction."

— Oregon commercial beekeeper

Ensuring Honey Quality

How Beekeepers Test Honey Ripeness

Three field-tested methods determine harvest readiness:

-

Refractometer testing (Most accurate)

- Place a honey droplet on the prism

- View moisture percentage through the eyepiece

- Calibrate weekly with distilled water

-

Shake test (Quick check)

- Tilt uncapped frame sideways

- Ripe honey stays in cells; unripe honey drips

-

Visual inspection

- Look for 80-90% wax capping coverage

- Check for nectar "gloss" disappearing from cells

Tools and Techniques for Moisture Control

| Tool | Purpose | Impact |

|---|---|---|

| Dehumidifiers | Maintains 40-50% RH in extraction rooms | Prevents ambient moisture absorption |

| Bucket heaters | Gently warms honey to 95°F (35°C) | Reduces viscosity for easier moisture evaporation |

| Ventilated storage | Allows air circulation around supers | Lowers moisture pre-extraction |

Pro Tip: Freeze high-moisture honey immediately after harvest to halt yeast activity until dehydration is possible.

Lessons from the Field

Case Study: Consequences of Premature Harvesting

A Texas apiary harvested 1.2 tons of honey at 19.5% moisture during a humid spell. Within weeks:

- 60% of jars showed bubbling and off-flavors

- Retailers returned $8,700 worth of product

- Brand reputation took 18 months to recover

Solution adopted: They now use HONESTBEE’s refractometer bundles to test every 10th frame during flow season.

Industry Standards for Harvesting and Storage

Leading commercial operations follow this sequence:

-

Pre-harvest prep

- Remove all uncapped frames 48 hours pre-extraction

- Run dehumidifiers in processing area

-

Extraction protocol

- Use radial extractors to minimize comb damage

- Filter through 200-micron mesh to remove debris

-

Post-harvest handling

- Store in food-grade buckets with airtight lids

- Monitor temperature (50-70°F/10-21°C ideal)

Ready to upgrade your harvest process? HONESTBEE’s commercial-grade refractometers and extraction kits help distributors and large apiaries maintain consistent honey quality—because every percentage point of moisture control translates to preserved flavor and extended shelf life. Contact our wholesale team for bulk equipment solutions tailored to your operation scale.

Next-season spoilage prevention starts with today’s moisture management decisions.

Visual Guide

Related Products

- Precision Honey Refractometer Instrument for Quality Assessment

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

Related Articles

- From Profit to Spoilage: The One Number Every Commercial Beekeeper Must Know

- From Ambiguity to Certainty: The Practical Case for Digital Honey Refractometers

- How Beekeepers Prevent Honey Spoilage Through Precision Moisture Control

- Mastering Honey Refractometer Basics: A Guide to Precision and Profitability

- The Unseen Architecture of Trust: Calibrating the Honey Refractometer