Selecting the ideal stainless steel screw pump capacity for honey processing isn’t just about moving liquid—it’s about maximizing efficiency while preserving product quality. Whether you’re an artisanal beekeeper or managing large-scale extraction lines, matching pump capacity to your operational demands ensures smoother workflows and better resource utilization.

Choosing the Ideal Pump Capacity for Your Honey Processing

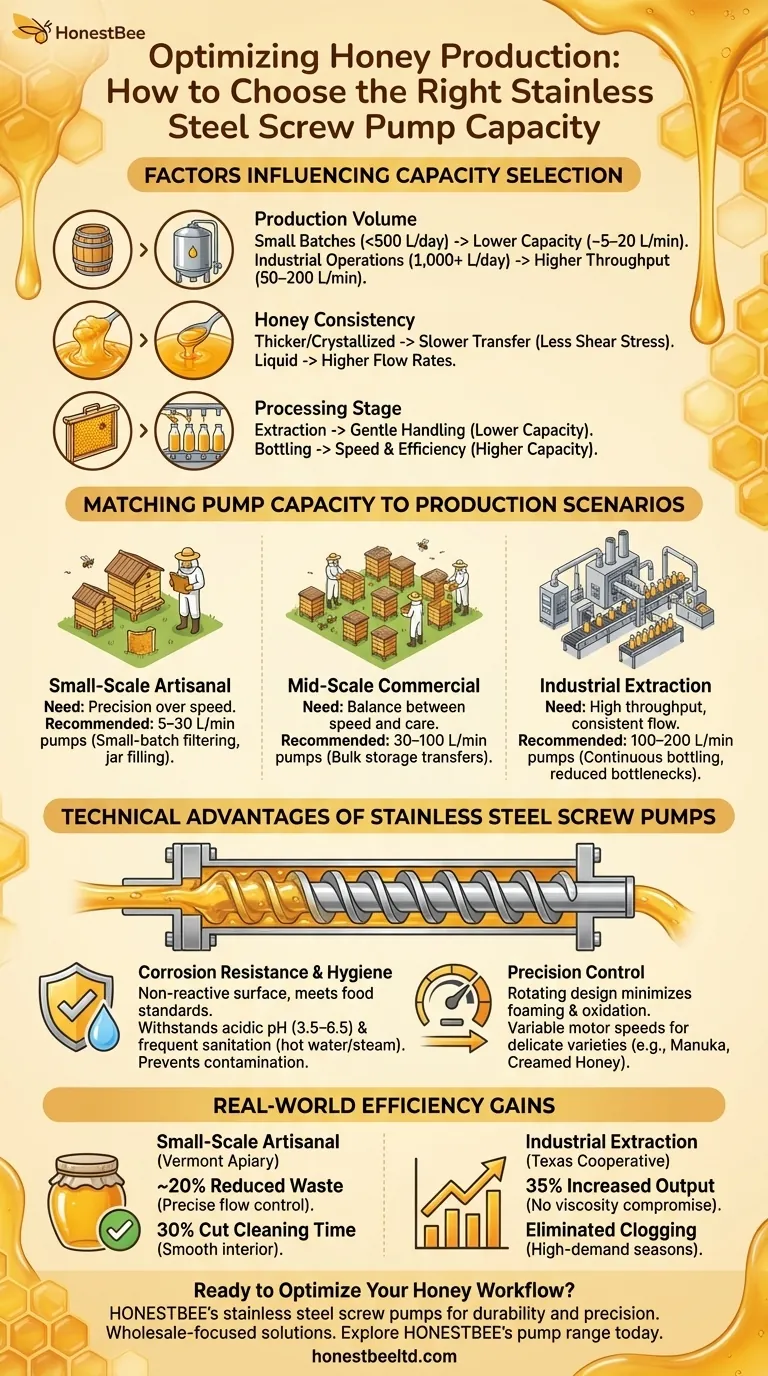

Factors Influencing Capacity Selection

Honey’s unique viscosity and variable flow properties mean pump capacity must account for:

- Production Volume: Small batches (under 500 liters/day) need lower-capacity pumps (~5–20 L/min), while industrial operations (1,000+ liters/day) require higher throughput (50–200 L/min).

- Honey Consistency: Thicker, crystallized honey demands slower, more controlled transfer to avoid shear stress, while liquid honey can tolerate higher flow rates.

- Processing Stage: Extraction from hives benefits from gentle handling (lower capacity), whereas bottling lines prioritize speed (higher capacity).

Matching Pump Capacity to Production Scenarios

-

Small-Scale Artisanal Operations

- Typical Need: Precision over speed.

- Recommended Capacity: 5–30 L/min pumps maintain control during small-batch filtering or jar filling.

-

Mid-Scale Commercial Apiaries

- Typical Need: Balance between speed and care.

- Recommended Capacity: 30–100 L/min pumps handle bulk storage transfers efficiently.

-

Industrial Extraction Facilities

- Typical Need: High throughput with consistent flow.

- Recommended Capacity: 100–200 L/min pumps reduce bottlenecks in continuous bottling lines.

Technical Advantages of Stainless Steel Screw Pumps

Corrosion Resistance and Hygiene Compliance

Stainless steel’s non-reactive surface prevents honey contamination and meets food-grade standards (e.g., FDA, EC 1935/2004). Unlike plastic or aluminum, it withstands:

- Acidic honey pH levels (3.5–6.5).

- Frequent sanitation with hot water or steam.

Precision Control for Viscous Liquids

The screw mechanism’s rotating design:

- Minimizes foaming or oxidation by reducing turbulence.

- Adjusts flow rate via variable motor speeds, critical for delicate honey varieties (e.g., Manuka or creamed honey).

Real-World Applications and Efficiency Gains

Case Study: Small-Scale Artisanal Honey Packaging

A Vermont apiary using a 15 L/min pump:

- Reduced honey waste by ~20% during jar filling due to precise flow control.

- Cut cleaning time by 30% with stainless steel’s smooth interior.

Case Study: Large-Scale Industrial Extraction Lines

A Texas honey cooperative upgraded to a 150 L/min pump:

- Increased output by 35% without compromising viscosity integrity.

- Eliminated pump clogging incidents during high-demand seasons.

Ready to Optimize Your Honey Workflow?

HONESTBEE’s stainless steel screw pumps combine durability and precision for apiaries of all sizes. Whether you’re a distributor supplying commercial beekeepers or a large-scale producer, our wholesale-focused solutions ensure you get the right capacity—without the guesswork. Explore HONESTBEE’s pump range today and streamline your honey processing.

Visual Guide

Related Products

- Honey Convey Pump Screw Honey Pump for Viscous Liquid

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Honey Press Wax Press with Tank

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

Related Articles

- How to Harvest Honey Naturally: A Beekeeper’s Guide to Crush & Strain

- The Bottleneck and the Bottle: A Systems Approach to Honey Filling

- Preserving the Golden Harvest: The Gentle Engineering of Honey Pumps

- Beyond the Strainer: The Engineering of Trust in Commercial Honey Production

- Optimizing Honey Filtration: How Mesh Sizes Shape Quality and Market Appeal