The Final, Perilous Journey of Honey

A commercial beekeeper stands before a full extractor. It represents the culmination of millions of flight hours by the bees and countless hours of human labor. The air is thick with the scent of success.

But between this tank of liquid gold and the final bottle lies a hidden moment of extreme risk. The simple act of moving the honey.

Most logistical problems in business are about speed and volume. But for honey, the primary challenge is preserving integrity. The final transfer is not a problem of brute force; it’s a problem of finesse. Using the wrong tool here is like having a concert pianist move their Steinway with a forklift.

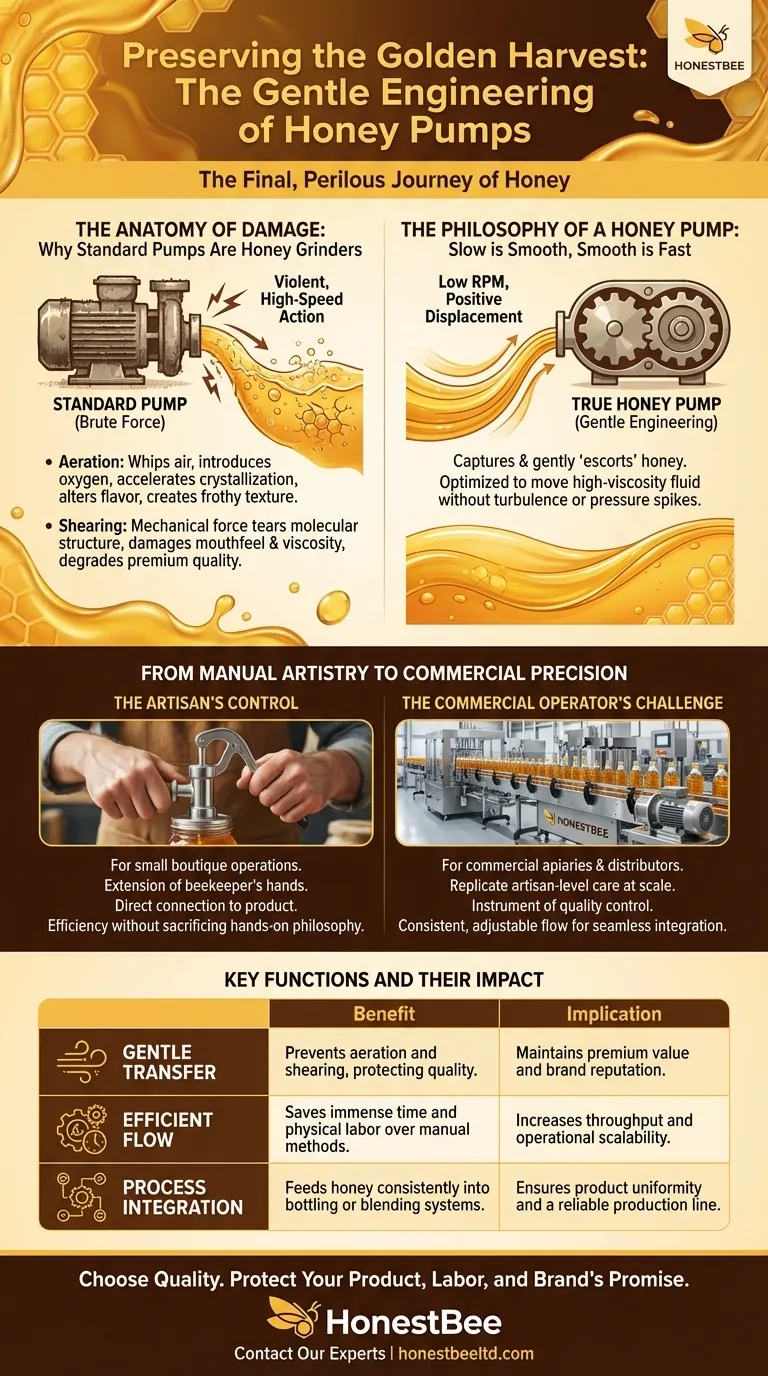

The Anatomy of Damage: Why Standard Pumps Are Honey Grinders

To understand the problem, you have to think like an engineer, but see the world through the honey's perspective. Honey is not a simple liquid like water. It’s a supersaturated solution of sugars, alive with delicate enzymes and aromatic compounds.

A standard pump—designed for water or chemicals—is an instrument of brute force. When it meets honey, two destructive things happen:

- Aeration: The pump’s violent, high-speed action whips air into the honey. These aren't just harmless bubbles. They introduce oxygen that can accelerate crystallization, alter the flavor profile, and create a frothy, undesirable texture.

- Shearing: The sheer mechanical force tears apart the honey's molecular structure. This physical breakdown damages the mouthfeel and viscosity, permanently degrading the premium quality you worked all season to achieve.

The tragic irony is that a tool meant to improve efficiency can become the very thing that ruins the product's value. It solves the problem of labor at the cost of the product itself.

The Philosophy of a Honey Pump: Slow is Smooth, Smooth is Fast

A true honey pump operates on a completely different philosophy. It isn't built for speed; it's built for gentleness.

This is the engineer's romance: designing a machine that respects the material it handles.

These pumps are typically positive displacement pumps (like gear or lobe pumps) that operate at a very low RPM. Instead of violently flinging the liquid, they capture a volume of honey and gently escort it through the system.

The entire design is optimized for a single goal: to move a high-viscosity fluid without introducing turbulence, pressure spikes, or agitation. The result is a smooth, laminar flow that protects the honey's delicate structure from start to finish.

From Manual Artistry to Commercial Precision

The right tool depends on the scale of your ambition. The underlying principle of gentle handling, however, remains the same.

The Artisan's Control

For small, boutique operations, a manual pump is an extension of the beekeeper's hands. It offers control and eliminates the mess of scooping, but more importantly, it maintains the artisan's direct connection to the product. It’s a step up in efficiency without sacrificing the hands-on philosophy.

The Commercial Operator's Challenge

For commercial apiaries and distributors, the challenge is different. The goal is to replicate that gentle, artisan-level care across thousands of gallons. This is where an electric honey pump becomes a non-negotiable cornerstone of the operation.

An electric pump isn't just a labor-saving device. It's an instrument of quality control at scale. By providing a consistent, gentle, and adjustable flow rate, it ensures that the first bottle of the batch has the exact same quality as the last. It integrates seamlessly into bottling lines, mixers, and clarifiers, forming the reliable heart of an efficient workflow.

For operations of this size, the equipment supplier is as critical as the equipment itself. You need a partner who understands the stakes. HONESTBEE specializes in supplying commercial-grade equipment built for the dual demands of efficiency and quality preservation. Our wholesale-focused model ensures that apiaries and distributors get the robust, reliable tools needed to protect their harvest and their reputation.

Key Functions and Their Impact

| Function | Core Benefit | Commercial Implication |

|---|---|---|

| Gentle Transfer | Prevents aeration and shearing, protecting quality. | Maintains premium value and brand reputation. |

| Efficient Flow | Saves immense time and physical labor over manual methods. | Increases throughput and operational scalability. |

| Process Integration | Feeds honey consistently into bottling or blending systems. | Ensures product uniformity and a reliable production line. |

Ultimately, choosing a honey pump isn't a mechanical decision; it's a business decision about quality. It reflects an understanding that the work isn't finished until the honey is safely in its final container, with its integrity perfectly intact.

Protect your product, your labor, and your brand's promise of quality by investing in the right equipment for the final, critical step of the journey. Contact Our Experts

Visual Guide

Related Products

- Honey Convey Pump Screw Honey Pump for Viscous Liquid

- Honey Convey Pump Economy Gear Pump for Viscous Liquid

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

Related Articles

- Optimizing Honey Production: How to Choose the Right Stainless Steel Screw Pump Capacity

- The Bottleneck and the Bottle: A Systems Approach to Honey Filling

- How to Harvest Honey Naturally: A Beekeeper’s Guide to Crush & Strain

- Optimizing Honey Filtration: How Mesh Sizes Shape Quality and Market Appeal

- Beyond the Strainer: The Engineering of Trust in Commercial Honey Production