For beekeepers, protecting wooden hives from rot and weather damage is a constant battle. While paint and chemical treatments have been go-to solutions for decades, wax dipping emerges as the superior method—offering deeper protection, longer lifespan, and eco-friendly benefits. This article breaks down the science, compares alternatives, and provides actionable steps to implement wax dipping effectively.

The Science Behind Wax Dipping

How Wax Penetration Prevents Rot

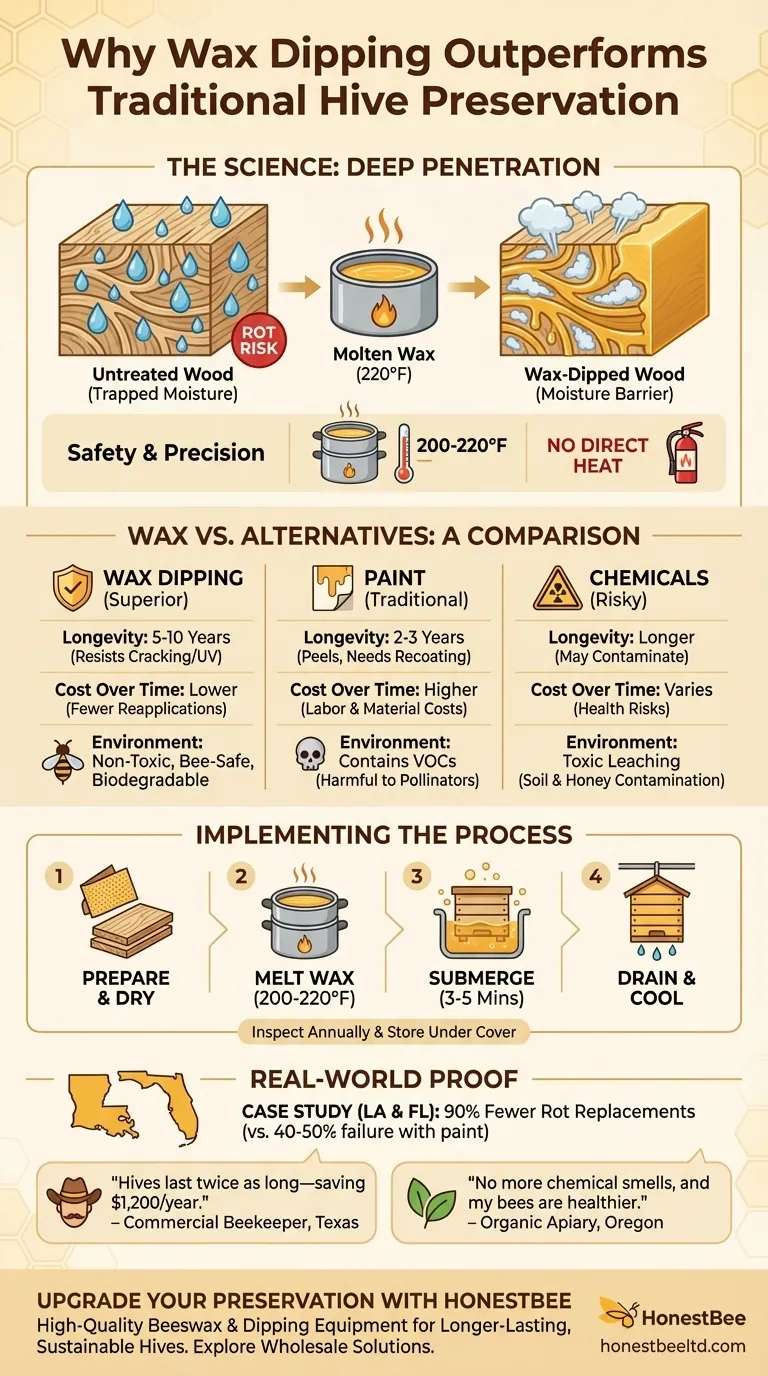

Wax dipping isn’t a surface-level treatment. By submerging wood in molten wax (heated to approximately 220°F), the wax displaces water trapped in the wood fibers, creating a moisture barrier that prevents fungal growth and rot. Unlike paint, which chips or peels, wax penetrates deeply, ensuring protection even in humid climates.

Temperature Precision and Safety

Melting wax requires careful temperature control:

- Use a double boiler or heat-resistant container (e.g., crockpot) to avoid overheating.

- Maintain temperatures below 220°F to prevent fire hazards.

- Never leave melting wax unattended—keep a fire extinguisher nearby.

This process is safer than chemical treatments, which often require toxic solvents or volatile fumes.

Wax Dipping vs. Alternatives

Longevity: Wax vs. Paint or Chemical Treatments

- Wax-dipped wood lasts 5–10 years without reapplication, as the wax resists cracking and UV damage.

- Painted wood typically needs recoating every 2–3 years due to peeling.

- Chemical preservatives (e.g., copper naphthenate) may last longer but can contaminate honey and harm bees.

Cost-Effectiveness Over Time

While wax dipping has higher upfront costs (equipment setup, bulk wax purchases), it reduces long-term expenses:

- Fewer reapplications mean lower labor and material costs.

- Less hive replacement due to rot saves commercial apiaries hundreds annually.

Environmental Impact Comparison

- Wax: Non-toxic, biodegradable, and safe for bees.

- Paint: Often contains VOCs (volatile organic compounds) harmful to pollinators.

- Chemical treatments: Risk leaching into soil or honey.

Implementing Wax Dipping Successfully

Step-by-Step Dipping Process

- Prepare the wood: Sand rough edges and dry thoroughly.

- Melt wax: Use a double boiler to heat wax to 200–220°F.

- Submerge equipment: Dip each piece for 3–5 minutes (until bubbles stop rising).

- Drain excess: Hang treated wood to cool; reuse dripped wax.

Equipment Maintenance After Treatment

- Inspect annually for wear; spot-treat with melted wax if needed.

- Store hives under cover to minimize weathering.

Real-World Proof

Case Study: Hive Survival Rates in Humid Climates

Beekeepers in Louisiana and Florida reported 90% fewer rot-related hive replacements after switching to wax dipping, compared to 40–50% failure rates with painted boxes.

Beekeeper Testimonials on Reduced Replacement Costs

- "After wax dipping, my hives last twice as long—saving me $1,200 per year." —Commercial beekeeper, Texas

- "No more chemical smells, and my bees are healthier." —Organic apiary, Oregon

Ready to Upgrade Your Hive Preservation?

HONESTBEE supplies high-quality beeswax and dipping equipment for commercial apiaries and distributors. By choosing wax dipping, you invest in longer-lasting hives, healthier bees, and sustainable practices.

Contact HONESTBEE today to explore wholesale solutions tailored to your beekeeping needs.

Visual Guide

Related Products

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- Professional 3-Bar Frame Grip with Integrated Hive Tool

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

Related Articles

- More Than Steel: How a Simple Hive Tool Dictates the Success of an Apiary

- The Typhoid Mary of the Apiary: Why Your Hive Tool is a Double-Edged Sword

- More Than Steel: The Hive Tool as a Vector for Apiary Health

- The Apiary as a System: Why Your Hive Tool is More Than Just Steel

- Beyond the Scrape: A Beekeeper's Protocol for Preventing Invisible Catastrophe