The most effective method for separating wax cappings from honey involves using water and gentle heat. When the mixture is warmed in water, the less-dense beeswax melts and floats to the surface, while the water-soluble honey dissolves. As the mixture cools, the wax solidifies into a clean cake on top, allowing for easy removal.

Your goal is not just to separate honey and wax, but to recover the maximum value from both. Understanding the trade-offs between different methods is key to preserving the quality of your honey while efficiently processing your beeswax.

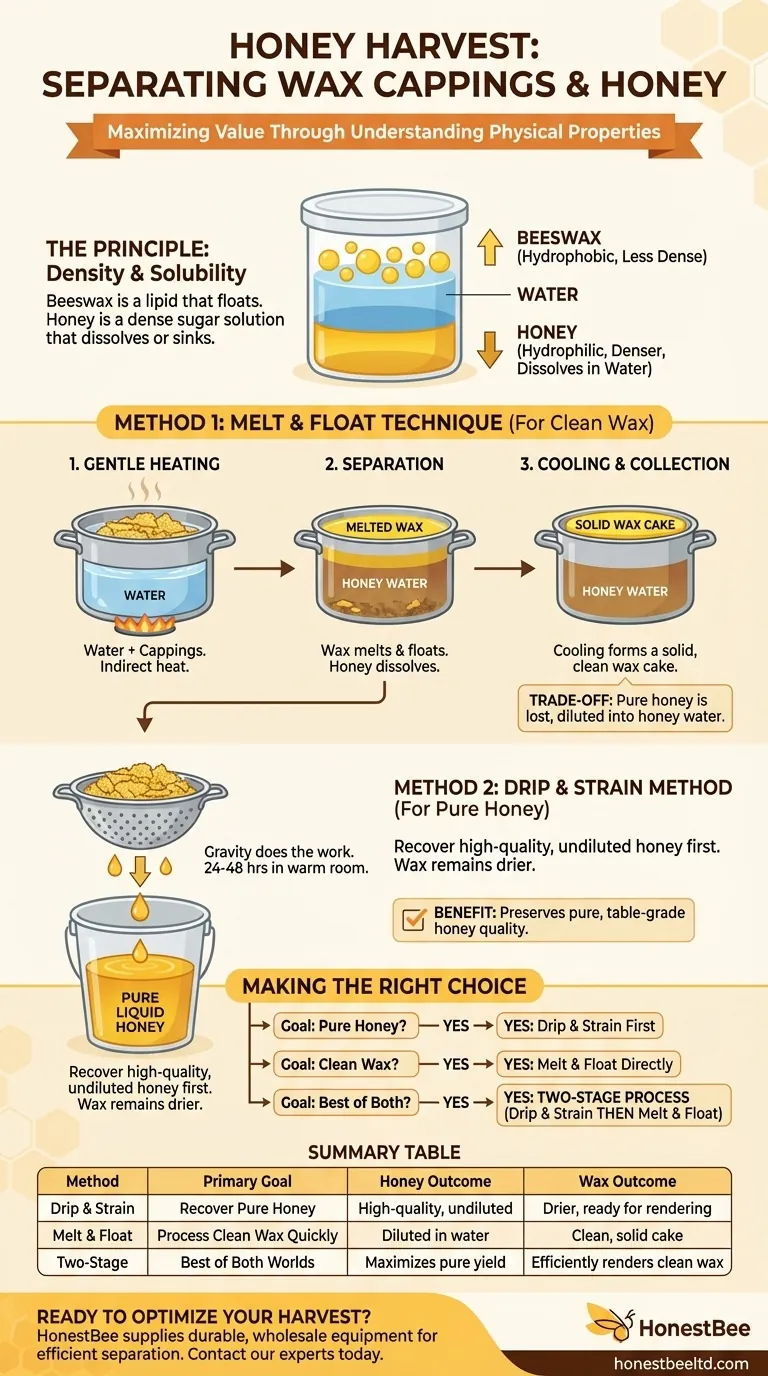

The Principle: Leveraging Density and Solubility

The separation process works by exploiting the fundamental physical properties of honey, wax, and water. This is the foundation of every technique.

How Wax Behaves

Beeswax is a lipid, meaning it is hydrophobic (it repels water) and is less dense than water. When heated past its melting point (around 145°F or 63°C), it becomes a liquid that will float on top of any water in the container.

How Honey Behaves

Honey is a supersaturated sugar solution, making it hydrophilic (it readily dissolves in water). It is also significantly denser than both water and wax, causing it to sink to the bottom of a container if not dissolved.

Method 1: The Melt and Float Technique

This is the most common method for processing cappings and is focused on producing clean, rendered beeswax.

Step 1: Gentle Heating

Place your wax cappings into a pot and cover them with water. It is crucial to use gentle, indirect heat, such as from a double boiler or a purpose-built wax melter. Direct, high heat can scorch the wax and, more importantly, degrade the quality of the honey.

Step 2: Melting and Separation

As the pot warms, the wax will melt and float to the surface. The honey trapped in the cappings will dissolve into the water below, creating what is often called "honey water." Any heavier debris, like propolis or dirt, will sink to the very bottom.

Step 3: Cooling and Collection

Turn off the heat and allow the pot to cool completely, which may take several hours. The liquid wax on the surface will harden into a solid disk. You can then easily lift this cake of clean wax from the pot.

Understanding the Trade-offs

No single method is perfect for all goals. Choosing the right approach depends on whether your priority is recovering pure honey or processing clean wax.

The Downside of Melting

The primary trade-off of the melt and float technique is the loss of pure honey. The honey dissolves into the water, resulting in a sweet liquid that is not concentrated honey. While this can be used for feeding bees or making mead, it is not the table-grade honey you started with.

An Alternative: The Drip and Strain Method

To recover pure, liquid honey, you must use gravity before introducing heat. Place your fresh cappings in a colander, nylon paint strainer bag, or a dedicated cappings strainer set over a food-grade bucket.

Let the cappings sit for 24-48 hours, ideally in a warm room. Gravity will do the work, pulling a significant amount of the pure, liquid honey away from the wax. This honey is perfectly preserved and ready for bottling. The remaining wax will be much drier and ready for the melting process.

Making the Right Choice for Your Goal

Your primary objective determines the best workflow for your harvest.

- If your primary focus is recovering the most pure honey: Always use the drip and strain method first. This maximizes your yield of high-quality, undiluted honey before you process the wax.

- If your primary focus is processing wax quickly: The melt and float method is the most direct path to clean beeswax, but you must accept that the honey will be diluted into the water.

- For the best of both worlds: Employ a two-stage process. First, drain the cappings for a day or two to recover the pure honey. Then, take the remaining semi-dry cappings and use the melt and float method to render your clean beeswax.

By separating your goals, you can efficiently capture the full value of your harvest.

Summary Table:

| Method | Primary Goal | Honey Outcome | Wax Outcome |

|---|---|---|---|

| Drip and Strain | Recover Pure Honey | High-quality, undiluted honey | Drier wax for later rendering |

| Melt and Float | Process Clean Wax Quickly | Honey is diluted into 'honey water' | Clean, solid cake of beeswax |

| Two-Stage Process | Best of Both Worlds | Maximizes pure honey yield first | Efficiently renders clean wax second |

Ready to Optimize Your Harvesting Process?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the durable, wholesale-focused supplies needed for efficient honey and wax separation. From high-capacity cappings strainers to reliable wax melters, our equipment is designed to help you maximize the value of every harvest.

Contact our expert team today to discuss your operation's needs and discover the right equipment solutions for you.

Visual Guide

Related Products

- Heavy Duty Stainless Steel Honey Processing Machine Decrystallizing Tank

- Electric Commercial Beeswax Melter for Factory Use

- Professional Thermostatic Conical Honey Melter

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

People Also Ask

- Why is a honey bucket warmer considered a valuable tool for honey storage? Preserve Quality & Streamline Bottling

- How many times can you decrystallize honey? The truth about quality loss with each cycle.

- What role do high-specification food-grade honey storage tanks play in the maturation process? | Pure Honey Solutions

- What is the heat method of processing honey? Balancing Shelf Life with Natural Quality

- What are the key features to look for in a honey warming source? Preserve Honey Quality with Gentle, Even Heat