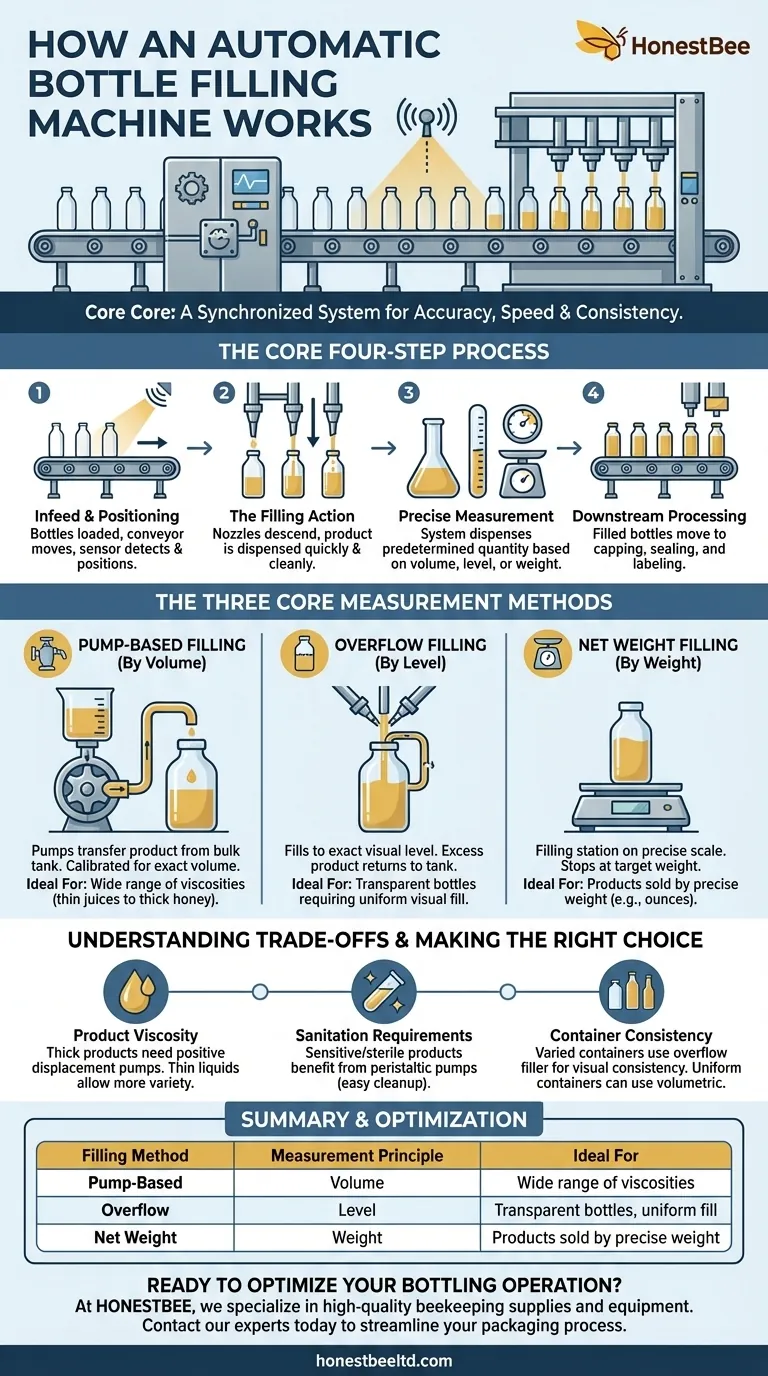

At its core, an automatic bottle filling machine is a synchronized system. It uses a conveyor to move empty bottles into position, a sensor to detect their presence, and a precision mechanism to dispense a specific amount of product before sending the filled bottles downstream for capping and labeling.

The real function of an automatic filler isn't just to put liquid in a bottle; it's to do so with exceptional accuracy, speed, and consistency. The key is understanding how it measures the product—by volume, level, or weight—as this determines the machine's ideal use.

The Core Four-Step Process

Every automatic filling machine, regardless of its specific technology, follows a fundamental sequence of operations designed for efficiency and minimal human intervention.

Step 1: Infeed and Positioning

The process begins with clean, empty bottles being loaded onto a conveyor belt. This belt transports the bottles in a single file line toward the filling station.

As the bottles approach, a sensor detects their presence and position, signaling the machine to halt the conveyor and secure the bottles for filling.

Step 2: The Filling Action

Once the bottles are correctly positioned, the filling nozzles descend into the bottle openings or position themselves directly above. The machine then dispenses the product.

This action is carefully programmed to be quick and clean, preventing spills or drips that could disrupt the operation.

Step 3: Precise Measurement

This is the heart of the machine's function. The system is programmed to dispense a predetermined quantity of product.

This measurement can be based on volume, weight, or fill level, ensuring that every bottle receives the exact same amount of product, run after run.

Step 4: Downstream Processing

After the filling cycle completes, the nozzles retract, and the conveyor moves the newly filled bottles away from the station.

They proceed to subsequent stations for capping, sealing, and labeling before being prepared for final packaging. Simultaneously, a new set of empty bottles moves into the filling station, and the process repeats.

How Machines Measure the Product: The Three Core Methods

The "magic" of an automatic filler lies in its dispensing technology. Different products and packaging goals require different methods for measuring the product accurately.

Pump-Based Filling (By Volume)

These machines use pumps—such as gear, lobe, or peristaltic pumps—to transfer the product from a bulk tank into the containers.

Each pump is calibrated to push an exact volume of liquid with each cycle. This method is excellent for a wide range of liquid viscosities, from thin juices to thick honey.

Overflow Filling (By Level)

Overflow fillers are designed to fill every bottle to the exact same visual level, which is critical for products sold in transparent containers.

Nozzles create a seal over the bottle opening and dispense liquid until it reaches an "overflow" port inside the nozzle. Excess product is then suctioned back to the main tank, preventing waste and ensuring a perfect cosmetic fill every time.

Net Weight Filling (By Weight)

For products where the exact weight is more important than the volume or fill level, a net weight filler is used.

Each filling station sits on a precise scale. The machine dispenses product until the scale registers the target weight, at which point a valve instantly shuts off the flow. This is the most accurate method for guaranteeing product quantity.

Understanding the Trade-offs

Choosing the right technology involves balancing several factors. There is no single "best" type of machine; the right choice depends entirely on the product and the business goal.

Product Viscosity

Thick, viscous products like creams or honey require the power of a positive displacement pump (like a gear or lobe pump) to be moved accurately. Thinner, free-flowing liquids can be handled by a wider variety of machine types.

Sanitation Requirements

Products that are sensitive, corrosive, or require sterile filling conditions often benefit from peristaltic pumps. In these systems, the product only ever touches a disposable, flexible tube, making cleanup and changeovers extremely fast and sanitary.

Container Consistency

If your bottles have slight variations in internal volume, an overflow filler is ideal because it guarantees the same visual fill level regardless of the container's exact capacity. A volumetric filler, by contrast, would result in visibly different fill levels.

Making the Right Choice for Your Product

To apply this knowledge, match the filling technology to your primary objective.

- If your primary focus is a uniform visual fill level in clear bottles: An overflow filler is the ideal solution to ensure aesthetic consistency.

- If your primary focus is product consistency by weight (e.g., selling by the ounce): A net weight filling machine provides the most accurate and reliable measurement.

- If your primary focus is handling high-viscosity liquids or ensuring sterile conditions: A pump-based filler, particularly one using a peristaltic or positive displacement pump, is the best fit.

Ultimately, selecting the right automatic filler depends on a clear understanding of your product's unique characteristics and your specific packaging goals.

Summary Table:

| Filling Method | Measurement Principle | Ideal For |

|---|---|---|

| Pump-Based Filling | Volume | Wide range of viscosities (juices to honey) |

| Overflow Filling | Level | Transparent bottles requiring uniform visual fill |

| Net Weight Filling | Weight | Products sold by precise weight (e.g., ounces) |

Ready to Optimize Your Bottling Operation?

Choosing the right automatic bottle filling machine is critical for maximizing your production line's efficiency, accuracy, and profitability. Whether you are a commercial apiary needing to handle viscous honey or a beekeeping equipment distributor looking for reliable solutions for your clients, the correct technology makes all the difference.

At HONESTBEE, we specialize in supplying high-quality, wholesale-focused beekeeping supplies and equipment. Our expertise can help you select the perfect filling machine to ensure consistent fills, reduce waste, and scale your production.

Contact our experts today to discuss your specific needs and discover how our equipment can streamline your packaging process.

Visual Guide

Related Products

- Semi-Automatic Pneumatic Bottle Capping Machine by HONESTBEE

- Automatic Honey Frame Uncapper Machine for Beekeeping

- Stainless Steel Triangle Support Honey Strainer and Filters

- Honey Gate Valve with Ergonomic Ball Handle Plastic Bee Honey Tap for Beekeeping Bottling and Honey Extractor Equipment

- Honey Concentrating and Filtering Dehumidifier Machine 2T Capacity for Honey

People Also Ask

- What is the importance of automated honey-filling machines? Boost Efficiency and Safety in Your Supply Chain

- What technologies are incorporated into honey filling machines? Piston, Pump, or Gravity for Your Production

- How do honey filtration and automated filling equipment contribute to commercial value? Boost Your Brand & ROI

- What key factors should be considered when choosing a honey-filling machine? Optimize Your Production Line

- Why is precision honey filling equipment critical for competitiveness? Secure Market Authority with Advanced Packaging

- Why is precision and consistency a crucial feature in a honey packaging machine? Maximize Profits and Quality

- What auxiliary machines are used with honey fillers? Build a Complete Automated Production Line

- What value do industrial honey filling machines provide? Optimize Your Final Stage Production & Market Reach