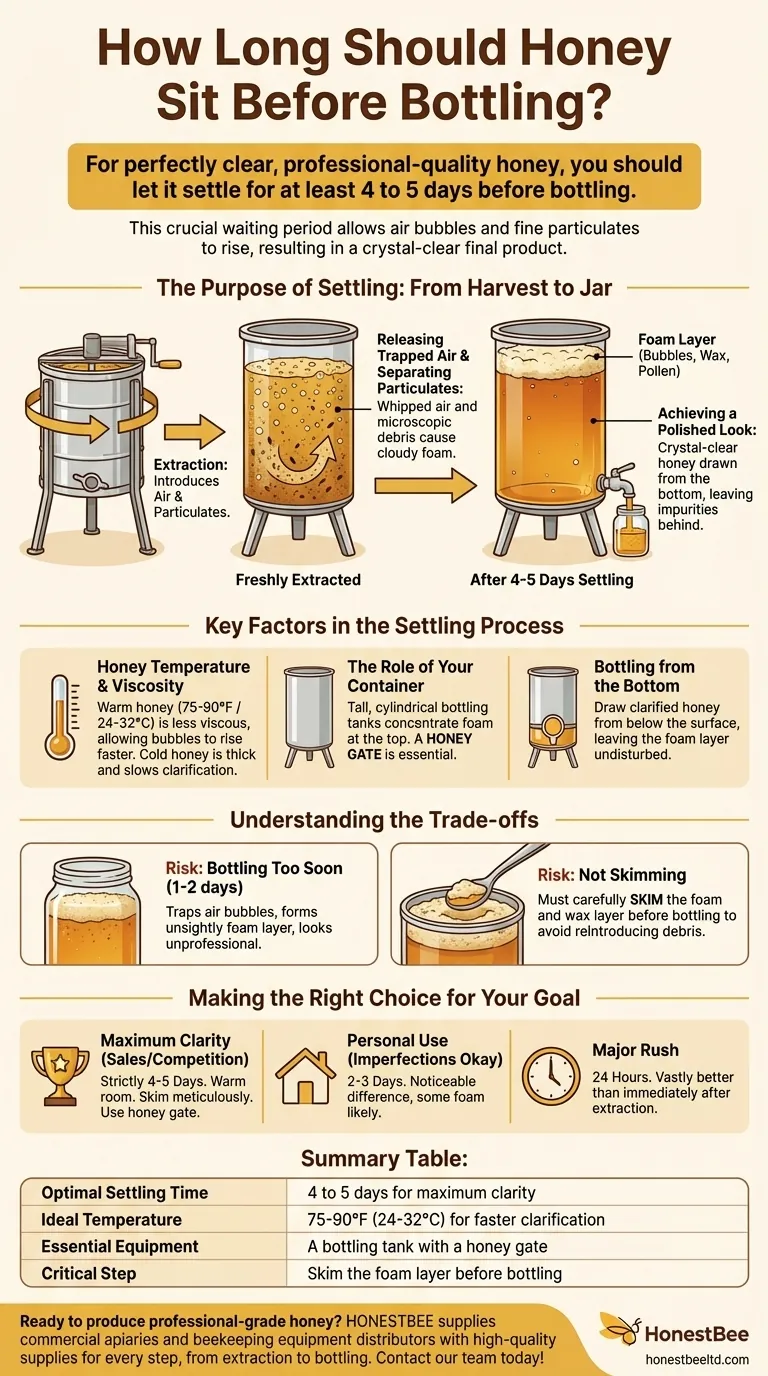

For perfectly clear, professional-quality honey, you should let it settle for at least 4 to 5 days before bottling. This crucial waiting period allows the tiny air bubbles and fine particulates introduced during extraction to naturally rise to the surface, resulting in a crystal-clear final product.

The goal of settling is not just to pass time, but to allow for natural clarification. Rushing this step is the most common reason for cloudy honey and foam inside the jar, directly impacting the quality and appeal of your final product.

The Purpose of Settling: From Harvest to Jar

After honey is extracted from the comb, it's often cloudy and full of air. The settling process is designed to correct this by allowing gravity to separate the pure honey from these imperfections.

Releasing Trapped Air

The process of spinning honey in an extractor, pumping it, and even pouring it whips a significant amount of air into the liquid. This creates thousands of tiny bubbles, resulting in a cloudy or foamy appearance. Letting the honey rest undisturbed gives these bubbles the time they need to slowly rise to the top.

Separating Fine Particulates

Even after straining, microscopic particles of wax, pollen, and other hive debris can remain suspended in the honey. During the settling period, these fine particulates will also rise to the surface, collecting in the same foamy layer as the air bubbles.

Achieving a Polished Look

The result of this process is crystal-clear honey from the bottom of your tank to just below the surface. This clarity is the hallmark of high-quality, carefully prepared honey and is what customers expect to see on a shelf.

Key Factors in the Settling Process

While 4-5 days is a reliable guideline, certain factors can influence how quickly your honey clarifies.

Honey Temperature and Viscosity

Warm honey is less viscous (thinner), which allows air bubbles to rise to the surface much more easily and quickly. Storing your settling tank in a warm room—ideally between 75-90°F (24-32°C)—can significantly aid the clarification process. Cold honey is thick and will hold onto air bubbles for much longer.

The Role of Your Container

Using a dedicated, food-grade bottling tank is ideal. These are typically tall and cylindrical, which helps concentrate the foam and particulates at the top. Most importantly, they are equipped with a honey gate or spigot near the bottom.

Bottling from the Bottom

A honey gate is essential for a clean bottling run. It allows you to draw the purely clarified honey from below the surface, leaving the entire top layer of foam and debris undisturbed in the tank.

Understanding the Trade-offs

Patience is key, and cutting corners at this stage has direct consequences.

The Risk of Bottling Too Soon

If you bottle your honey after only a day or two, you will trap countless microscopic air bubbles in the jars. These bubbles will eventually rise, forming a distinct layer of foam at the top of every jar. This looks unprofessional and can be mistaken for spoilage by uninformed consumers.

The Risk of Not Skimming

After the settling period, a thick layer of foam and wax will be on the surface. Before bottling, you must carefully skim this layer off with a spatula or large spoon. Failing to do so risks reintroducing this debris back into the honey as you drain the tank.

Making the Right Choice for Your Goal

Use your desired outcome to determine your approach to settling.

- If your primary focus is maximum clarity for sales or competition: Strictly follow the 4-5 day settling period in a warm room, skim meticulously, and bottle using a honey gate.

- If your primary focus is for personal use and you don't mind imperfections: A shorter period of 2-3 days will still make a noticeable difference, though some foam in the jars is likely.

- If you are in a major rush: Even letting the honey settle for 24 hours is vastly better than bottling it immediately after extraction.

Patience during the settling process is the final, critical step that transforms your hard-won harvest into beautiful, shelf-stable honey.

Summary Table:

| Factor | Key Insight |

|---|---|

| Optimal Settling Time | 4 to 5 days for maximum clarity. |

| Ideal Temperature | 75-90°F (24-32°C) for faster clarification. |

| Essential Equipment | A bottling tank with a honey gate. |

| Critical Step | Skim the foam layer before bottling. |

Ready to produce professional-grade honey? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the high-quality supplies needed for every step of the process, from extraction to bottling. Our wholesale-focused operations ensure you get the reliable equipment to maximize your honey's quality and appeal. Contact our team today to discuss your apiary's needs!

Visual Guide

Related Products

- Hexagonal Glass Honey Jars with Metal Lug Caps Elegant Versatile Packaging

- Inverted Squeezable Honey Jar with No Drip Flip Top Cap for Easy Pouring

- Stainless Steel Honey Tank Stand for Honey Storage

- Premium Diamond-Faceted Glass Honey Dispenser

- Stainless Steel Honey Press Wax Press with Tank

People Also Ask

- What role does specialized packaging play in marketing and preservation? Master Honey Branding & Quality

- Why are Glass Jars preferred as storage equipment for honey? The Ultimate Choice for Purity and Long-Term Quality

- What are the primary functional benefits of high-standard glass packaging for honey? Protect Purity and Brand Value

- Why are transparent glass containers utilized in honey storage stability studies? Simulating Real-World Quality Decay

- Why is it necessary to use storage containers with tight-fitting lids? Prevent Honey Spoilage and Loss