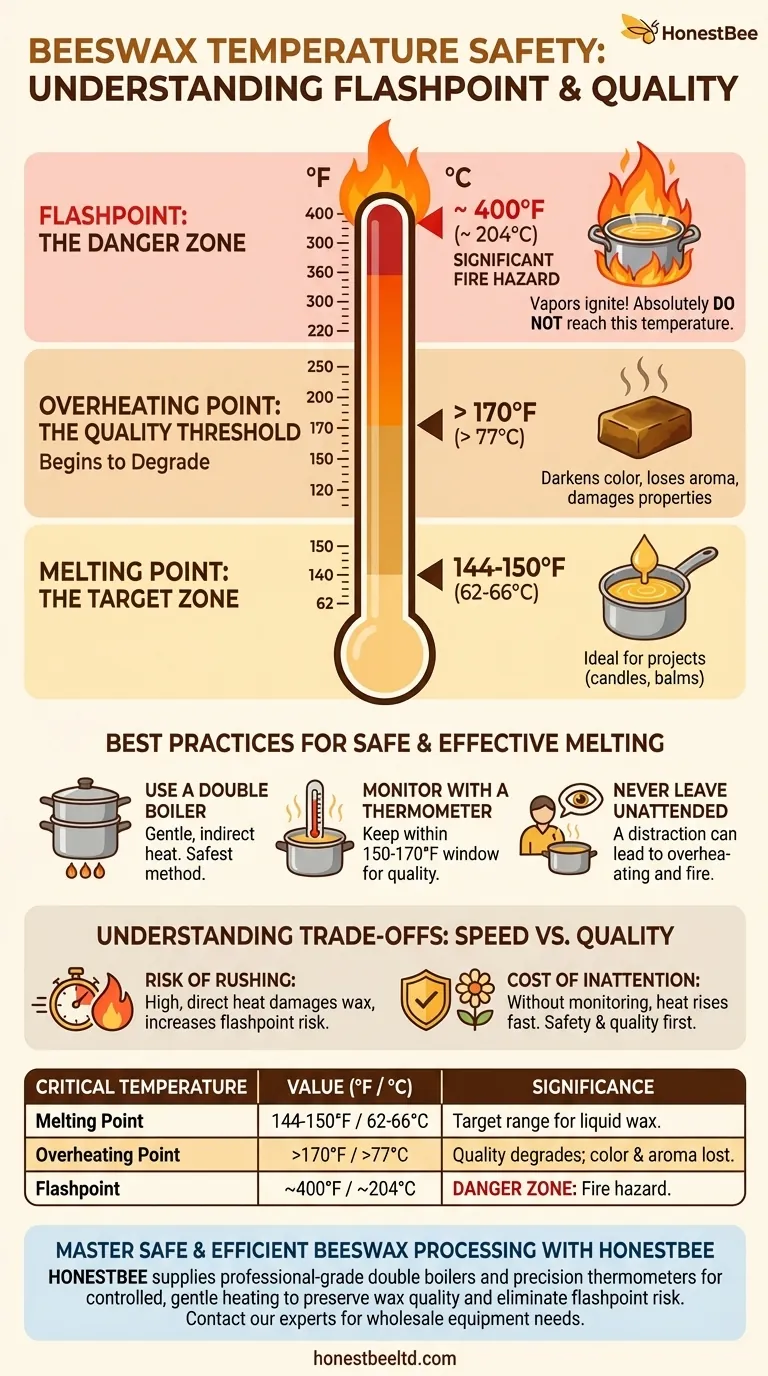

The flashpoint of pure beeswax is approximately 400°F (204°C). This is the critical temperature at which the wax produces enough flammable vapor to ignite if an ignition source is present. Monitoring the temperature is essential not only to prevent a dangerous fire but also to preserve the quality, color, and natural aroma of the wax during the melting process.

The challenge of working with beeswax isn't just about melting it; it's about controlling the heat. Exceeding the optimal melting range risks ruining its quality, while approaching the flashpoint creates a significant fire hazard.

The Two Critical Temperatures of Beeswax

To work with beeswax safely and effectively, you must understand two key temperature thresholds: the point where it melts and the point where it becomes a hazard.

Melting Point: The Target Zone

The melting point of beeswax is between 144°F and 150°F (62-66°C). This is the temperature range you are aiming for to turn the solid wax into a workable liquid for projects like candles, balms, or polishes.

Overheating Point: The Quality Threshold

While not a safety risk, exceeding 170°F (77°C) begins to degrade the beeswax. Overheating can cause the wax to darken, lose its subtle, honey-like scent, and potentially damage its beneficial properties.

Flashpoint: The Danger Zone

The flashpoint at 400°F (204°C) is the absolute upper limit and represents a serious fire risk. At this temperature, the wax vapors can ignite suddenly, creating a dangerous situation that is difficult to control. Never allow your wax to approach this temperature.

Best Practices for Safe and Effective Melting

Controlled heating is the core principle for success. Rushing the process with high, direct heat is the most common mistake.

Use a Double Boiler

The safest method for melting beeswax is a double boiler (or a makeshift version with a heat-proof bowl over a pot of simmering water). This provides gentle, indirect heat, making it nearly impossible to scorch the wax or accidentally reach its flashpoint.

Monitor with a Thermometer

Use a candy or candle-making thermometer to track the temperature precisely. This allows you to keep the wax within the ideal 150°F to 170°F window, ensuring it is fully melted without compromising its quality.

Never Leave Melting Wax Unattended

A pot of melting wax should be treated with the same caution as a pot of hot oil. A distraction can quickly lead to overheating and a potential fire hazard.

Understanding the Trade-offs: Speed vs. Quality

When melting beeswax, you are constantly balancing the desire for speed against the need for safety and quality.

The Risk of Rushing

Applying high, direct heat will melt the wax faster, but it dramatically increases the risk of scorching the wax. This damages its color and aroma and brings you unnecessarily closer to the flashpoint.

The Cost of Inattention

The significant gap between the ideal melting temperature (around 150°F) and the flashpoint (400°F) can create a false sense of security. However, without monitoring, a stovetop on high can cause the temperature to rise much faster than you expect.

How to Apply This to Your Project

Your approach to heating beeswax should be guided by your end goal.

- If your primary focus is safety: Always use a double boiler and never leave the melting wax unattended.

- If your primary focus is preserving quality and aroma: Use a thermometer to ensure the temperature stays below 170°F (77°C).

- If your primary focus is efficiency: Recognize that the most efficient method is one that doesn't require you to start over after scorching a batch or dealing with a fire.

Ultimately, mastering the gentle and controlled heating of beeswax is the key to achieving safe, consistent, and high-quality results.

Summary Table:

| Critical Temperature | Value (°F / °C) | Significance |

|---|---|---|

| Melting Point | 144-150°F / 62-66°C | Target range for melting wax into a workable liquid. |

| Overheating Point | >170°F / >77°C | Wax quality degrades; color and aroma are lost. |

| Flashpoint | ~400°F / ~204°C | DANGER ZONE: Wax vapors can ignite, creating a fire hazard. |

Master Safe & Efficient Beeswax Processing with HONESTBEE

As a commercial apiary or beekeeping equipment distributor, maintaining product quality and workshop safety is paramount. HONESTBEE supplies professional-grade beekeeping supplies and equipment through wholesale-focused operations to help you achieve just that.

Our range of high-quality double boilers and precision thermometers provides the controlled, gentle heating essential for preserving the color and aroma of your beeswax while eliminating the risk of reaching its dangerous flashpoint.

Ready to enhance your operation's safety and product quality? Contact our experts at HONESTBEE today to discuss your wholesale equipment needs and ensure every batch of wax is processed perfectly.

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Electric Flatting and Embossing Machine with Tray for Beekeeping

People Also Ask

- What is the role of beeswax processing equipment? Maximize Your Apiary Profit Through Full Resource Utilization

- What are some alternative methods for melting beeswax? Safely Melt Wax with Slow Cookers & Solar Melters

- What is the principle of operation of a wax melter? Master Efficient Beekeeping Wax Processing

- How should liquid beeswax be poured and stored after melting? Expert Guide for Pure, Long-Lasting Beeswax Blocks

- How should processed beeswax be stored? Keep Your Wax Pure for Candles & Cosmetics

- How does the use of a Solar Melter improve beeswax quality? Upgrade to High-Purity Wax Processing

- What is the role of a double jacket pan in queen cell prep? Preserve Wax Integrity for Apis cerana Rearing

- What are the features of an electric wax melter? Gain Unmatched Control and Consistency